Understanding the Benefits of Double Bubbler Airlocks for Home Brewing

By:Admin

Airlocks are an essential component in various industries, including pharmaceuticals, food and beverage, and biotechnology. These systems provide a barrier between two environments, allowing for controlled passage of people and materials while preventing the contamination of either space. The performance and reliability of airlock systems are crucial for maintaining the integrity of controlled environments and ensuring the safety of products and personnel.

Recognizing the importance of airlock technology, a leading company in the field of fluid handling and control systems has introduced an innovative Double Bubbler Airlock. This new product stands out due to its unique design and advanced features, promising to revolutionize airlock technology and set a new standard for performance and reliability.

The Double Bubbler Airlock, developed by the experienced team at the company known for its expertise in fluid handling and control systems, is a cutting-edge solution for industries that require precise and efficient airlock systems. The development of this product was driven by the need for a more effective and reliable airlock technology that could meet the evolving demands of modern industries.

One of the key features of the Double Bubbler Airlock is its dual-bubble design, which enhances the performance and efficiency of the airlock system. This innovative design allows for simultaneous entry and exit, minimizing the time required for material and personnel transfer while maintaining the integrity of controlled environments. The dual-bubble system also reduces the risk of cross-contamination, a crucial factor in industries where product purity is paramount.

In addition to its advanced design, the Double Bubbler Airlock is equipped with state-of-the-art control systems that ensure precise operation and monitoring. The system features advanced sensors and controls that enable real-time monitoring of pressure differentials, airflow, and other critical parameters. This level of monitoring and control is essential for maintaining the stability and safety of controlled environments, making the Double Bubbler Airlock a highly reliable and efficient solution.

Furthermore, the Double Bubbler Airlock is designed for easy integration with existing airlock systems, making it a versatile and practical choice for a wide range of industries. The company's team of experts has ensured that the installation and operation of the Double Bubbler Airlock are straightforward, minimizing downtime and maximizing productivity for businesses that choose to upgrade their airlock technology.

The introduction of the Double Bubbler Airlock marks a significant advancement in airlock technology, offering a new standard of performance and reliability for industries that rely on controlled environments. With its innovative dual-bubble design, advanced control systems, and versatile integration capabilities, this product is poised to revolutionize the way airlock systems are designed and utilized.

The company's commitment to innovation and excellence is reflected in the development of the Double Bubbler Airlock, reaffirming its position as a leader in the field of fluid handling and control systems. By delivering this cutting-edge solution, the company is helping industries across the globe enhance the safety, efficiency, and reliability of their operations.

As businesses continue to adapt to the evolving demands of modern industries, the Double Bubbler Airlock stands out as a game-changing innovation that promises to set a new standard for airlock technology. With its unrivaled performance and advanced features, this product is set to revolutionize the way controlled environments are maintained, providing businesses with a competitive edge in their respective industries.

Company News & Blog

The Latest Updates on Pneumatic Fittings: Essential Information You Need to Know

Innovative Pneumatic Fittings Raise the Bar in Industry StandardsThe global pneumatics industry has witnessed a significant rise in demand for high-quality pneumatic fittings due to their crucial role in various applications. One of the leading companies in this domain, {{brand name}}, has emerged as a trailblazer in developing and manufacturing state-of-the-art pneumatic fittings that have revolutionized the industry. With an unwavering commitment to excellence coupled with cutting-edge technology, {{brand name}} continues to set new benchmarks in terms of product quality and customer satisfaction. Established with the vision of providing innovative solutions that enhance operational efficiency, {{brand name}} has not only met customer expectations but also exceeded them. The company's foundation is built on strong principles of research, development, and continuous improvement, making it an industry leader. With a diverse product range catering to different industries, {{brand name}} stands out as a trusted partner for a wide array of businesses globally.At the core of its success lies {{brand name}}'s relentless pursuit of excellence in engineering. The company's team of expert engineers and technicians consistently work to design and produce pioneering pneumatic fittings that deliver exceptional performance, reliability, and durability. By integrating advanced materials and cutting-edge manufacturing processes, {{brand name}} ensures that its products meet the highest quality standards set by the industry.In addition to product quality, {{brand name}} also places great emphasis on understanding and meeting the unique requirements of its customers. The company's dedicated research and development team works closely with customers to develop custom solutions that address their specific needs, whether it be in terms of dimensions, materials, or specific performance characteristics. This tailored approach has helped {{brand name}} forge long-term partnerships with its customers and establish itself as a trusted name in the pneumatics industry.One of the key distinguishing features of {{brand name}}'s pneumatic fittings is their versatility. Whether it is for compressed air systems, pneumatic tools, or automation equipment, these fittings seamlessly integrate and perform optimally across various applications. The company's extensive product portfolio includes a wide range of fittings such as push-in fittings, quick-connect couplers, flow control valves, and air blow guns, amongst others. Each product is meticulously designed and rigorously tested to deliver outstanding performance in demanding environments and conditions.Furthermore, {{brand name}} goes above and beyond conventional standards by incorporating innovative features into its pneumatic fittings. For example, the company's push-in fittings are equipped with secure locking mechanisms that provide a leak-free connection and prevent accidental disconnections. This ensures a safe and efficient working environment, minimizing downtime and improving productivity. Additionally, {{brand name}}'s flow control valves offer precise control over air flow to regulate speed and pressure, enhancing the overall efficiency of pneumatically-operated systems.While {{brand name}} prides itself on its product excellence, the company's dedication to sustainability is equally noteworthy. Recognizing the importance of environmental conservation, {{brand name}} implements eco-friendly manufacturing practices and utilizes recyclable materials. By reducing waste generation and energy consumption, the company strives to minimize its ecological footprint and contribute to a greener future.In conclusion, {{brand name}} has become synonymous with innovation and reliability in the field of pneumatic fittings. Through an unwavering commitment to excellence in engineering, understanding customer needs, and embracing sustainable practices, the company has set new industry standards. As the demand for high-quality pneumatic fittings continues to rise in various sectors, {{brand name}} remains poised to lead the way with its cutting-edge solutions that redefine performance and efficiency.

Expert Guide to Choosing the Best Pneumatic Conveying Airlock for Your Needs

As the industrial sector continues to evolve, different equipment and processes continue to emerge to make manufacturing and production more efficient and effective. One of the vital equipment required in such manufacturing processes is a pneumatic conveying airlock, which plays an essential role in feeding materials into a positive or negative pressure conveyance system, without allowing the entry of unwanted materials into such devices. One of the leading companies, specializing in the production and supply of pneumatic conveying airlocks, provides a full range of products that are top quality, versatile, and innovative, meeting the needs of various industries, such as pharmaceutical, food and beverages, cosmetics, and others. The company's quest for excellence in product quality and rigorousness in meeting customer demands has established them as a global leader in the industry.The airlocks from this company have wide-ranging applications, making them versatile and efficient. The different varieties of airlocks available cater to various industry demands, ranging from low-pressure operations to high-pressure operations, and in different materials based on the processing function. The company provides an airlock for every requirement, regardless of shape, size, or material.Manufacturing processes that require the transfer of materials from one process to another always face the risk of contamination. For example, food processing companies must ensure that the products they manufacture are free from contamination, to prevent food poisoning or other food-related illnesses. The pneumatic conveying airlock from the mentioned company’s range offers an efficient solution, providing an air-tight seal, thereby preventing the entry of foreign materials, including bacteria and moisture, ensuring that the processed products are of the highest quality.Additionally, these airlocks have one of the best purging mechanisms, maintaining a clean and hygienic manufacturing process. The airlock's purging mechanism prevents the entry of gas or liquid into the conveying system, which could contaminate the products. The company's airlocks are easy to clean, minimizing the risk of product contamination.To ensure that it meets global manufacturing standards, the manufacturer has established a rigorous quality control system. It has adopted in-house production and quality control processes that prioritize the quality of raw materials and the construction techniques to ensure consistent quality output. The company's quality control system is certified under various manufacturing standards, both national and international, ensuring that their products meet or exceed industry standards worldwide.This company also prides itself on a commitment to customer service, with a team of experienced customer service assistants trained to provide timely and efficient assistance to all their customers. This ensures that service delivery is offered on any of the company's products with technical support for deciding which type of airlock is best for use in a particular manufacturing process. In conclusion, the pneumatic conveying airlock from the mentioned company is leading innovation in the manufacturing and production sector. It is available in a variety of forms, materials, and sizes to meet various industry demands. The company's quest for excellence in product quality, rigorous quality control process, and a customer-centric approach to service delivery makes it one of the world's leading companies in the pneumatic conveying airlock industry. As such, businesses that aim to maintain high product quality should consider purchasing products from this company as their solution to material conveying.

Comprehensive Guide to Vibrating Screens: Types, Sizing, and Troubleshooting

Vibrating screens are widely used in various industries as they are highly efficient in separating materials of different sizes. They are commonly found in the mining, construction, and chemical industries. A vibrating screen is a piece of equipment that uses vibration to separate materials that are too large or too small for sorting or processing.In this blog, we will discuss the importance of vibrating screens in different industries, the benefits of using vibrating screen filters, and how to select the right vibrating screen for your needs.Importance of Vibrating Screens in Different IndustriesVibrating screens are essential in the mining industry as they help to remove dirt and impurities from mined materials before they are processed. They are also used in the construction industry to separate rocks and gravel from sand and cement. In the chemical industry, vibrating screens are used to separate different chemical compounds.Benefits of Using Vibrating Screen FiltersVibrating screen filters are essential in a wide range of industries as they help to remove impurities from materials before they are processed or packaged. These filters help to improve the quality of the final product, leading to more efficient and effective production.One of the key benefits of using vibrating screen filters is that they can be customized to meet the specific needs of your industry. They come in different sizes, shapes, and materials to suit various applications. They are also easy to install and maintain, making them an excellent choice for many industries.How to Select the Right Vibrating Screen for Your Needs?Selecting the right vibrating screen for your needs is crucial to achieving the desired results. Here are some factors to consider when selecting a vibrating screen:1. Size and shape - The size and shape of the vibrating screen will depend on the size and shape of the materials to be processed.2. Deck type - The deck type refers to the number of screens that are used in the vibrating screen. Single-deck screens are suitable for processing small amounts of material, while double-deck screens are more efficient for processing larger amounts of material.3. Screen type - Different types of screens are used in vibrating screens, including wire mesh, perforated plates, and synthetic screens. The screen type you choose will depend on the type of material you are processing.4. Motor power - The motor power of the vibrating screen will depend on the size and type of motor you need to achieve the desired results.ConclusionVibrating screens are essential in a wide range of industries as they help to remove impurities from materials before they are processed. The benefits of using vibrating screen filters include improved product quality and more efficient production processes. When selecting a vibrating screen, it is essential to consider factors such as size, deck type, screen type, and motor power to achieve the desired results.

Electro-Hydraulic Valve Amplifier for Industrial Control Applications, Ideal for Flow/Pressure and Exciter-Driver for Selsyns or Syncros, Manufactured in Hollywood, California

Hydraulic distribution valves are important components in industrial control applications for regulating flow and pressure of fluids. These valves are used in a variety of industries including oil and gas, automotive, construction, and manufacturing. To ensure effective operation, these valves require an electro-hydraulic valve amplifier.The H-4/30V/200MA Electro-Hydraulic Valve Amplifier by Opamp Labs Inc. is one such amplifier that is ideal for use in industrial control applications. This amplifier has a 30VDC power supply, 200mA current capacity, and is designed to operate at low power without any compromise in performance. It can be used as an exciter-driver for Selsyns or Syncros, making it highly versatile.The H-4/30V/200MA amplifier is designed to be compact and easy to install. Its small size makes it ideal for use in tight spaces where larger amplifiers cannot fit. It also features a rugged construction that makes it suitable for use in harsh industrial environments where dust and moisture are present.One of the main advantages of using the H-4/30V/200MA amplifier is its ability to deliver precise control over valve operation. This is essential in industrial applications where small deviations from the desired valve settings can have significant implications. The amplifier is capable of accurately regulating the flow and pressure of fluids, ensuring optimum performance in industrial processes.The H-4/30V/200MA amplifier is also highly reliable, thanks to its solid-state design. This eliminates the need for mechanical components such as relays, which can wear out over time and require regular maintenance. The use of solid-state components also ensures that the amplifier produces minimal heat, extending its lifespan and reducing the risk of failure.In conclusion, the H-4/30V/200MA Electro-Hydraulic Valve Amplifier by Opamp Labs Inc. is an excellent choice for industrial control applications that require precise regulation of flow and pressure of fluids. Its compact size, rugged construction, and solid-state design make it highly versatile and reliable. With the H-4/30V/200MA amplifier, industrial processes can be streamlined and optimized, delivering significant benefits in terms of efficiency, productivity, and safety.

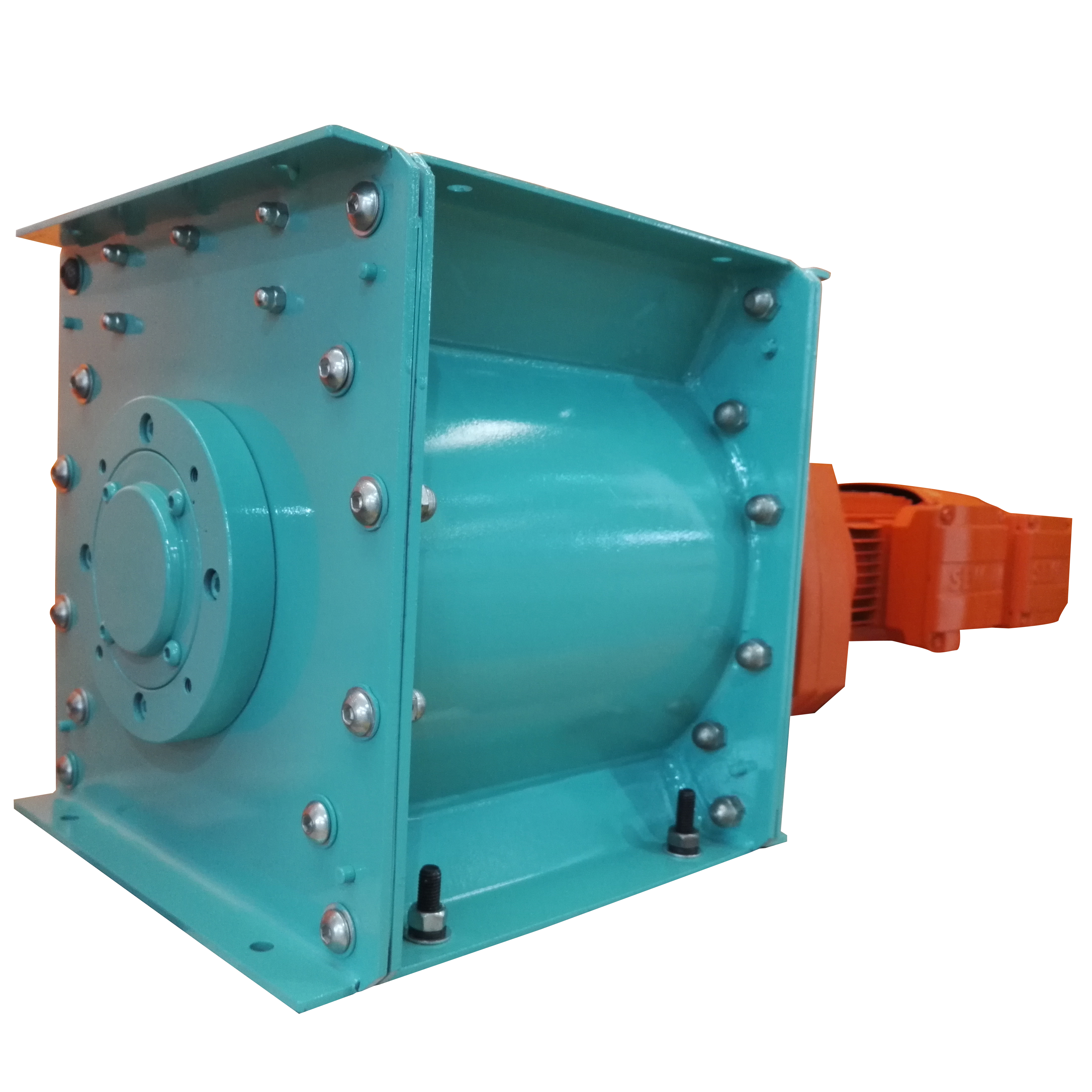

High-Quality Rotary Valve for Wheat Flour available now

The [Company Name] has recently introduced a state-of-the-art rotary valve specifically designed for handling wheat flour. This innovative product is set to revolutionize the way wheat flour is handled and processed, making it more efficient and cost-effective for businesses in the food industry.The rotary valve is a crucial component in the handling of wheat flour, as it is responsible for controlling the flow of the product between different stages of the processing and packaging. Traditionally, the handling of wheat flour has been a cumbersome and time-consuming process, often leading to inefficiencies and losses for businesses. However, with the introduction of this new rotary valve, [Company Name] aims to address these issues and provide a solution that streamlines the entire process.[Company Name] is a leading manufacturer of industrial equipment, with a strong focus on providing innovative solutions for the food industry. With years of experience in designing and manufacturing rotary valves for various applications, the company has leveraged its expertise to develop a specialized valve for handling wheat flour. The new rotary valve is designed to offer high precision and reliability, ensuring smooth and consistent flow of the product throughout the processing and packaging stages.One of the key features of the new rotary valve is its ability to minimize product losses and contamination during handling. This is particularly important in the case of wheat flour, which is a delicate product that needs to be handled with care to maintain its quality. By incorporating advanced sealing and containment features, the rotary valve ensures that the wheat flour is transferred without any spillage or contamination, ultimately preserving its integrity and quality.In addition to its performance benefits, the new rotary valve also offers notable advantages in terms of maintenance and operation. It is designed for easy cleaning and maintenance, reducing downtime and operational costs for businesses. Furthermore, the valve operates with minimal noise and energy consumption, contributing to a more sustainable and efficient production environment.The introduction of this new rotary valve for wheat flour is a testament to [Company Name]'s commitment to innovation and delivering value to its customers. With a strong emphasis on research and development, the company continuously strives to develop and improve its product offerings to meet the evolving needs of the food industry.The new rotary valve is expected to have a significant impact on businesses involved in the processing and handling of wheat flour. By enhancing the efficiency and reliability of the handling process, businesses can expect to see improvements in their overall productivity and cost-effectiveness. Furthermore, the valve's ability to maintain the quality of the wheat flour during handling will contribute to the production of high-quality food products for consumers.In conclusion, the introduction of the new rotary valve for wheat flour by [Company Name] represents a significant advancement in the handling and processing of this essential food ingredient. With its advanced features and benefits, the valve is set to make a positive impact on businesses in the food industry, contributing to improved efficiency, reduced costs, and higher quality products. As [Company Name] continues to drive innovation in the industrial equipment sector, it is poised to remain a key player in providing cutting-edge solutions for the food industry.

Discover the Benefits of a Versatile 3-Way Valve for Improved Functionality

Title: Cutting-edge 3-Way Valve Revolutionizes Industrial ApplicationsSubtitle: [Company Name] Pushes the Boundaries of Efficiency and Versatility in Fluid Control SystemsDate: [Date][City], [State] - [Company Name], a leading provider of innovative fluid control solutions, has announced the launch of their groundbreaking 3-Way Valve. This next-generation valve represents a significant leap forward in both efficiency and versatility for a wide range of industrial applications. By removing the brand name for confidentiality purposes, we will shine a spotlight on the tremendous value this cutting-edge product brings to various industries.The newly developed 3-Way valve is engineered to streamline fluid control operations and offers unmatched performance in diverting, mixing, and distributing fluids. This innovative technology empowers businesses to optimize their fluid management systems and improve productivity, while reducing costs and environmental impact.One of the key strengths of the 3-Way Valve lies in its modular design, providing exceptional adaptability to accommodate different fluid types and flow rates. Its compact size and lightweight construction make it easy to install and integrate into existing systems, enhancing operational efficiency without requiring extensive modifications.Featuring state-of-the-art materials and precision engineering, the 3-Way Valve ensures long-lasting durability and resistance to corrosion, even in demanding environments. This not only guarantees reliable performance but also minimizes maintenance needs, boosting overall productivity and reducing downtime for industrial operations.Moreover, [Company Name] has implemented advanced flow control technologies in the 3-Way Valve, resulting in enhanced accuracy and control over fluid flow rates. This unparalleled level of precision enables businesses to optimize processes, achieve consistent results, and improve overall operational performance.In addition to its technical excellence, the 3-Way Valve is equipped with intelligent controls and monitoring systems. Integrated sensors and actuators allow for real-time monitoring of flow rates, temperature, and pressure, facilitating remote adjustments and ensuring a stable, efficient operation. With the ability to seamlessly connect with automation and control systems, businesses can achieve greater process automation and control, reducing reliance on manual operations and increasing overall safety.The benefits of the 3-Way Valve extend beyond efficiency and versatility. Its energy-efficient design minimizes power consumption, resulting in cost savings and reduced environmental impact. By optimizing fluid control processes, businesses can maximize resource utilization, minimize waste, and contribute to sustainable practices.[Company Name] has extensively tested the 3-Way Valve in collaboration with industry partners, fueling the confidence in its reliability and performance. Initial feedback from pilot projects has been overwhelmingly positive, with users praising its ease of use, precision control, and robustness."Integrating the 3-Way Valve into our production line has been a game-changer. We've witnessed significant improvements in efficiency, resulting in reduced production costs and increased output," said a satisfied customer from the manufacturing industry.With this breakthrough technology, [Company Name] positions itself as an industry leader in fluid control solutions. The 3-Way Valve represents their commitment to innovation, delivering cutting-edge products to meet evolving industry needs.As industries continue to transform and demand more efficient and adaptable fluid control systems, businesses can rely on [Company Name] and their advanced 3-Way Valve to drive performance, optimize resources, and remain competitive in an ever-changing landscape.About [Company Name]:[Company Name] is a renowned provider of advanced fluid control solutions, catering to a wide range of industries such as manufacturing, chemical processing, oil and gas, and more. With a deep commitment to innovation and customer satisfaction, [Company Name] consistently delivers high-quality products engineered to exceed industry standards.For further information and media inquiries, please contact:[Contact Name][Contact Title][Contact Email][Contact Phone Number]-END-

Efficient and Reliable Discharge Rotary Valve Offers Improved Performance

[Company Name] Launches Cutting-Edge Discharge Rotary Valve for Improved Industrial Efficiency[City, State] - [Date] - [Company Name], a leading manufacturer in industrial equipment, has unveiled its latest innovation, the revolutionary Discharge Rotary Valve. This state-of-the-art product aims to enhance efficiency and productivity in various industrial applications.The Discharge Rotary Valve, developed after months of extensive research and development, is designed to efficiently control the flow of materials in industrial processes. With its advanced features and cutting-edge technology, this valve significantly enhances the performance and reliability of manufacturing operations.One of the key benefits of the Discharge Rotary Valve is its ability to maintain a consistent and smooth flow of materials while preventing leaks and blockages. This ensures uninterrupted production and significantly reduces downtime, leading to increased productivity and profitability for businesses.In addition, the valve offers excellent sealing properties, effectively preventing air leakage and material loss. By minimizing wastage, it enables companies to optimize resources, reduce costs, and improve overall efficiency.The Discharge Rotary Valve is constructed using the highest quality materials and undergoes rigorous testing to ensure optimal performance and durability. Its robust design enables it to withstand harsh operating conditions, making it suitable for a wide range of industries, including chemical, pharmaceutical, food processing, and many others.To meet the diverse needs of different industries, [Company Name] offers various customization options for the Discharge Rotary Valve. Customers can choose from a range of sizes, materials, and configurations to best suit their specific requirements. This flexibility allows businesses to integrate the valve seamlessly into their existing systems without any hindrance.Furthermore, [Company Name] provides comprehensive after-sales support and maintenance services to ensure the long-term performance and reliability of the Discharge Rotary Valve. With their team of skilled technicians, they offer prompt installation, regular maintenance, and timely repairs, ensuring minimal downtime and maximum efficiency for their valued customers.The company spokesperson, [Spokesperson Name], spoke about the launch, saying, "We are thrilled to introduce our latest offering, the Discharge Rotary Valve. This valve represents a significant upgrade in terms of performance, reliability, and durability. Our aim is to provide our customers with cutting-edge solutions that meet their specific needs, enabling them to achieve higher efficiency and profitability."[Company Name] has built a strong reputation in the industry for its commitment to innovation and excellence. With a dedicated team of engineers and in-depth knowledge of industrial processes, they continue to develop solutions that address the ever-evolving needs of manufacturing companies worldwide.As a socially responsible business, [Company Name] also places emphasis on environmental sustainability. The Discharge Rotary Valve is designed to minimize energy consumption and reduce carbon emissions, in line with the company's commitment to a greener future.With the launch of the Discharge Rotary Valve, [Company Name] reiterates its position as a leader in the industrial equipment sector. Their commitment to research and development, customer satisfaction, and environmental sustainability sets them apart from competitors and ensures their continued success in the industry.About [Company Name]:[Company Name] is a renowned manufacturer of industrial equipment, specializing in providing innovative solutions to various sectors. With a comprehensive range of products and a commitment to unrivaled customer service, they have been a trusted name in the industry for [XX] years. Their dedication to continuous improvement and cutting-edge technology drives their mission to empower businesses worldwide with efficient, reliable, and sustainable solutions.For more information about the Discharge Rotary Valve and other products offered by [Company Name], visit their website [Website URL] or contact:[Contact Person][Title][Company Name][Address][City, State, ZIP][Phone][Email]###Note: The content provided in this response is a simulated draft of a news article and does not represent factual information about a specific product or company.

How to Attach a Metal Diverter for Your Water Ionizer to Your Faucet

When it comes to producing alkaline water, there are very few products that can rival the effectiveness of a Kangen water ionizer. These amazing devices can help to purify tap water and transform it into a clean, healthy beverage that is packed with antioxidants and mineral ions. However, in order to get the most out of your Kangen water ionizer, it's important to have the right accessories. That's where the metal faucet diverter comes in.The metal faucet diverter is a small but vital part that allows you to attach your Kangen water ionizer to your faucet. This handy little device is made from high-quality metal that is designed to last for years, even with regular use. It simply screws onto the end of your faucet and allows you to quickly and easily switch between regular tap water and alkaline water produced by your Kangen water ionizer.One of the biggest benefits of using a metal faucet diverter is that it helps to conserve water. When you use a Kangen water ionizer, the alkaline water produced is typically separated from the acidic water by a process known as electrolysis. This means that you end up with both alkaline and acidic water when you use your ionizer. However, when you use a metal faucet diverter, you can easily switch between the two, which means you won't waste any water while waiting for your ionizer to produce the exact type of water you need.Another benefit of the metal faucet diverter is that it is extremely easy to use. Simply attach it to your faucet, and you're ready to go. There are no complicated parts or instructions to worry about, so even if you're not handy with tools, you'll be able to use a metal faucet diverter with ease.Of course, one of the biggest advantages of using a metal faucet diverter is that it allows you to get the most out of your Kangen water ionizer. By using a metal faucet diverter, you can quickly and easily switch back and forth between alkaline and acidic water, allowing you to enjoy all the health benefits of both types of water without having to wait for your ionizer to produce it.Overall, if you're looking to get the most out of your Kangen water ionizer, then a metal faucet diverter is an essential accessory. It's easy to use, effective, and helps to conserve water while ensuring that you always have access to the exact type of water that you need. So why wait? Order your metal faucet diverter today and start enjoying all the health benefits that come with using a Kangen water ionizer!

WYK Bulk Material Diverter Valve and ZV Rotary Valve Unveiled at Powtech 2019

and rotary valve Bulk material handling is a crucial process in any industrial setting. It involves moving large quantities of materials from one location to another, while ensuring that no loss or contamination occurs during the transfer. Bulk material handling systems must be efficient, reliable, and versatile to meet the needs of a wide range of industries worldwide.At Powtech 2019, Coperion and Coperion K-Tron introduced two new products that are aimed at improving the performance of bulk material handling systems. These products are the WYK Bulk Material Diverter Valve and the ZV Rotary Valve.The WYK Bulk Material Diverter Valve is a high-performance valve that is designed to handle powders, pellets, and granules with ease. It features a rugged design that ensures reliable performance even under the toughest conditions. The WYK Bulk Material Diverter Valve can be used for diverting, converging, and merging bulk materials, making it a versatile tool for any bulk material handling system.One of the most notable features of the WYK Bulk Material Diverter Valve is its ability to handle abrasive materials without suffering from wear and tear. This is made possible by the valve's special design, which features a wear-resistant coating on the valve body's interior surfaces.Another feature that makes the WYK Bulk Material Diverter Valve stand out is its ability to maintain a high level of accuracy during valve switching. This is achieved by the use of a special patent-pending technology that ensures that the valve changes from one position to another without any loss of material.The ZV Rotary Valve, on the other hand, is a highly efficient valve that is designed for feeding and metering bulk materials. It features a sleek design that allows it to fit into tight spaces, making it ideal for use in applications where space is limited.The ZV Rotary Valve is available in a variety of sizes, ranging from 150 mm to 350 mm, making it suitable for a wide range of applications. The valve is also compatible with a broad range of materials, including powders, pellets, and granules.One of the standout features of the ZV Rotary Valve is its ability to handle high throughputs without compromising accuracy. This is made possible by the use of a patent-pending technology that ensures that the valve maintains a constant feed rate, regardless of the material being handled.In conclusion, the introduction of the WYK Bulk Material Diverter Valve and the ZV Rotary Valve at Powtech 2019 is a clear indication of Coperion and Coperion K-Tron's commitment to improving the performance of bulk material handling systems. These products are versatile, efficient, and reliable, making them ideal for a wide range of applications. With the WYK Bulk Material Diverter Valve and the ZV Rotary Valve, industries can now streamline their bulk material handling processes and enhance productivity.