Discover the Benefits of a Versatile 3-Way Valve for Improved Functionality

By:Admin

Subtitle: [Company Name] Pushes the Boundaries of Efficiency and Versatility in Fluid Control Systems

Date: [Date]

[City], [State] - [Company Name], a leading provider of innovative fluid control solutions, has announced the launch of their groundbreaking 3-Way Valve. This next-generation valve represents a significant leap forward in both efficiency and versatility for a wide range of industrial applications. By removing the brand name for confidentiality purposes, we will shine a spotlight on the tremendous value this cutting-edge product brings to various industries.

The newly developed 3-Way valve is engineered to streamline fluid control operations and offers unmatched performance in diverting, mixing, and distributing fluids. This innovative technology empowers businesses to optimize their fluid management systems and improve productivity, while reducing costs and environmental impact.

One of the key strengths of the 3-Way Valve lies in its modular design, providing exceptional adaptability to accommodate different fluid types and flow rates. Its compact size and lightweight construction make it easy to install and integrate into existing systems, enhancing operational efficiency without requiring extensive modifications.

Featuring state-of-the-art materials and precision engineering, the 3-Way Valve ensures long-lasting durability and resistance to corrosion, even in demanding environments. This not only guarantees reliable performance but also minimizes maintenance needs, boosting overall productivity and reducing downtime for industrial operations.

Moreover, [Company Name] has implemented advanced flow control technologies in the 3-Way Valve, resulting in enhanced accuracy and control over fluid flow rates. This unparalleled level of precision enables businesses to optimize processes, achieve consistent results, and improve overall operational performance.

In addition to its technical excellence, the 3-Way Valve is equipped with intelligent controls and monitoring systems. Integrated sensors and actuators allow for real-time monitoring of flow rates, temperature, and pressure, facilitating remote adjustments and ensuring a stable, efficient operation. With the ability to seamlessly connect with automation and control systems, businesses can achieve greater process automation and control, reducing reliance on manual operations and increasing overall safety.

The benefits of the 3-Way Valve extend beyond efficiency and versatility. Its energy-efficient design minimizes power consumption, resulting in cost savings and reduced environmental impact. By optimizing fluid control processes, businesses can maximize resource utilization, minimize waste, and contribute to sustainable practices.

[Company Name] has extensively tested the 3-Way Valve in collaboration with industry partners, fueling the confidence in its reliability and performance. Initial feedback from pilot projects has been overwhelmingly positive, with users praising its ease of use, precision control, and robustness.

"Integrating the 3-Way Valve into our production line has been a game-changer. We've witnessed significant improvements in efficiency, resulting in reduced production costs and increased output," said a satisfied customer from the manufacturing industry.

With this breakthrough technology, [Company Name] positions itself as an industry leader in fluid control solutions. The 3-Way Valve represents their commitment to innovation, delivering cutting-edge products to meet evolving industry needs.

As industries continue to transform and demand more efficient and adaptable fluid control systems, businesses can rely on [Company Name] and their advanced 3-Way Valve to drive performance, optimize resources, and remain competitive in an ever-changing landscape.

About [Company Name]:

[Company Name] is a renowned provider of advanced fluid control solutions, catering to a wide range of industries such as manufacturing, chemical processing, oil and gas, and more. With a deep commitment to innovation and customer satisfaction, [Company Name] consistently delivers high-quality products engineered to exceed industry standards.

For further information and media inquiries, please contact:

[Contact Name]

[Contact Title]

[Contact Email]

[Contact Phone Number]

-END-

Company News & Blog

ANSI-standard Inverted Pressure Balance Lubricated Plug Valves available

Inverted Pressure Balance Lubricated Plug Valve According to ANSI API 599 and API 6DValves are integral components in pipelines used for controlling the flow of liquids and gases. There are different types of valves, and each type has unique features that make it suitable for specific applications. One type of valve that has gained popularity in recent years is the Inverted Pressure Balance Lubricated Plug Valve according to ANSI.Inverted Pressure Balance Lubricated Plug Valve or IPB valve is a type of valve that is commonly used in hydrocarbon, petrochemical, and chemical applications. It is designed to provide effective sealing and reliable operations even at high pressures and temperatures. The valve has a plug-like structure with a hole in its center that allows the flow to pass through.The IPB valve is designed to operate with a minimum amount of torque required to open and close the valve. This is made possible through the use of an inverted pressure balance design that allows the pressure inside the valve to balance with the pressure outside the valve. As a result, the valve can be easily and smoothly operated, reducing the risk of damage and wear and tear.Another key feature of the IPB valve is its lubrication system. The valve is designed to be equipped with a lubrication system that allows for easy and regular maintenance. The lubrication system helps to ensure that the valve’s plug and stem are always well-lubricated, reducing the risk of corrosion and enhancing the valve’s lifespan.The ANSI standards for Inverted Lubricated Plug Valve, namely API 599 and API 6D, are the benchmarks for the manufacturing and quality control of such valves. These standards specify the design, material, and testing requirements for IPB valves. Manufacturers who abide by these standards are more likely to produce high-quality valves that operate effectively and efficiently.In conclusion, the Inverted Pressure Balance Lubricated Plug Valve according to ANSI is an ideal option for those looking for a reliable and efficient valve for their applications. With its unique design and lubrication system, the IPB valve can operate smoothly and reliably, even in high temperatures and pressures. It is essential to choose a manufacturer who strictly adheres to the ANSI standards to ensure that you get a high-quality valve that meets your requirements.

Discover the Best Rubber Valve for Your Needs: a Comprehensive Guide

Rubber Valve – The Ultimate Solution for Efficient Flow ControlIn today's fast-paced world, efficiency is of paramount importance. Every industry strives to achieve maximum productivity in the shortest possible time. One of the key factors that play a role in improving efficiency is flow control. Be it in oil and gas, power generation, water treatment, or chemical industries; flow control is a vital aspect that can make or break the process.Enter Rubber Valve. A revolutionary flow control solution that has been making waves in the industry. Rubber Valve is a new-age valve that has become the go-to choice for many industries due to its unique design and outstanding performance. Let's take a closer look at what sets Rubber Valve apart from its competitors.Advanced DesignRubber Valve has a unique design that outperforms traditional valves. The valve is made of a body, seat, and a flexible rubber diaphragm. When the valve is in the closed position, the rubber diaphragm is pressed against the seat, ensuring a tight seal. When the valve is in the open position, the diaphragm flexes allowing the fluid to pass through.The rubber diaphragm is the key component of Rubber Valve. It is made from a specially formulated elastomer that can withstand the harshest conditions. The elastomer is resistant to corrosion, abrasion, and chemicals, making Rubber Valve suitable for a wide range of applications.Efficient Flow ControlRubber Valve provides efficient flow control, ensuring accurate regulation of the fluid flow. The flexible diaphragm allows for precise control of the valve's opening and closing, making it ideal for applications where flow control is critical.Rubber Valve also provides a higher Cv value than traditional valves, making it possible to achieve the same flow rate with a smaller valve size. This means that industries can save on initial costs, space requirements, and maintenance expenses.Low maintenanceRubber Valve is designed to be low maintenance, ensuring that industries can focus on their core activities. The rubber diaphragm requires no lubricants, eliminating the need for regular maintenance. The valve is also self-draining, making it suitable for applications where the fluid needs to be completely drained from the system.The valve is made of a few components, making it easy to disassemble and assemble, reducing downtime during maintenance. The diaphragm is also replaceable, ensuring a longer valve life.ApplicationsRubber Valve is suitable for a wide range of applications, including oil and gas, power generation, chemical, water treatment, and pharmaceutical industries. The valve is ideal for applications where a tight seal is critical, and efficient flow control is necessary.In the oil and gas industry, Rubber Valve is used in drilling, production, and refining applications. The valve's resistance to corrosion, abrasion, and chemicals make it ideal for these harsh environments.In the chemical industry, Rubber Valve is used in the transportation of chemicals, processing, and storage applications, where there is a need for precise flow control.In the water treatment industry, Rubber Valve is used in municipal and industrial applications, including wastewater treatment, drinking water treatment, and desalination plants, where flow control is essential.ConclusionRubber Valve is a game-changer in the flow control industry. Its unique design, efficient flow control, low maintenance, and versatility make it the go-to choice for many industries. The valve has proven to provide reliable and consistent performance, ensuring that industries can achieve maximum productivity with minimum downtime.Rubber Valve is committed to providing its customers with high-quality, innovative solutions that meet their unique needs. They have an expert team of engineers who work closely with customers to ensure that they get the best-valued solution. If you are looking for a flow control solution that offers long-term value, look no further than Rubber Valve.

Types of Rotary Valve: Applications, Components and Limitations of Rotary Airlock Valve - Engineering Learn

Globe Valve Made of Carbon Steel: A Reliable Solution for Process Control

Carbon Steel Globe Valves: High-Quality Products at an Affordable PriceCarbon steel globe valves are essential components in many industrial processes, serving as critical elements for regulating flow, pressure, and temperature. These valves are commonly used in various applications such as refineries, petrochemical plants, and power stations. When it comes to choosing the right valve for your application, it is crucial to consider factors like pressure rating, material compatibility, and cost.As one of the leading manufacturers of carbon steel globe valves, {company} has been providing high-quality valves at an affordable price for more than a decade. With a focus on innovation and customer satisfaction, we have earned a reputation as a trusted supplier of industrial valves worldwide.Our carbon steel globe valves are designed to withstand harsh environments and high-pressure applications, ensuring reliable performance and long-lasting durability. Our valves are made using high-quality materials and state-of-the-art technology, ensuring that they meet industry standards and comply with safety regulations.One of the key features of our carbon steel globe valves is their versatility, which means they can be used in various applications across different industries. Whether you're working in oil and gas, chemical processing, or power plants, our carbon steel globe valves are up for the task.We offer carbon steel globe valves in different sizes, ranging from 1/2" to 24", with pressure ratings up to 2500 PSI. We also offer customization options to meet the specific needs of your application. Our valves are available in different end connections, such as flanged, threaded, and butt-weld, to ensure easy installation and maintenance.In addition to our high-quality products, we pride ourselves on our customer service. Our team of experts is always available to help you choose the right valve for your application, provide technical support, and assist you with any questions or concerns you may have.At {company}, we are committed to providing our customers with the best value for their money. We understand that cost is a crucial factor in any industrial application, which is why we offer our carbon steel globe valves at an affordable price without compromising on quality.In conclusion, carbon steel globe valves are essential components in many industrial applications, and choosing the right valve can make a significant difference in your operations. With our focus on innovation, quality, and customer satisfaction, {company} is the ideal partner for all your industrial valve needs. Contact us today to learn more about our carbon steel globe valves or to request a quote.

New gaming console to compete with popular models in the market

[Header]: Breakthrough Technology Announcement: A New Player Emerges in the Valve Industry[Subheading]: Introducing EmergeTech: Revolutionizing Valve Solutions[Date]: [Current Date][City, Country] - In a groundbreaking development in the valve industry, a previously unknown company, EmergeTech, has emerged as a potential disruptor with its revolutionary valve technology. With their cutting-edge solutions and forward-thinking approach, EmergeTech aims to redefine the industry norms and offer unparalleled performance and reliability.Established in [Year], EmergeTech has silently been working behind the scenes, refining their valve technology to perfection. This breakthrough development is poised to shake the valve industry to its core by offering a range of innovative solutions based on advanced engineering principles.While EmergeTech aims to keep their technology under wraps, a sneak peek into their vision reveals their commitment to developing valves that not only outperform traditional models but also excel in sustainability and energy efficiency. Their research and development teams have been tirelessly working to embody their philosophy of harmony between performance and environmental responsibility. The company's focus on eco-friendly manufacturing and processes shows their dedication to a greener future.EmergeTech's valves go beyond being mere mechanical devices and are designed to be intelligent and adaptable. Equipped with the latest sensor technology, their valves can dynamically adjust and optimize the flow of various substances, ensuring peak performance under different conditions. This adaptability not only results in enhanced efficiency but also complements the evolving needs of diverse industries.One of the company's significant accomplishments is their breakthrough in fluid control. EmergeTech's fluid valves boast exceptional precision, enabling smoother flow regulation compared to their traditional counterparts. Industries such as oil and gas, water management, and chemical processing are expected to benefit greatly from this technology, boosting productivity and reducing wastage.Aside from their technological advancements, EmergeTech prides itself on its customer-centric approach. They aim to develop long-term partnerships with their clientele, offering tailored solutions and dedicated support throughout the implementation and maintenance stages. Coupled with their commitment to continuous improvement, this client-focused strategy sets them apart from other players in the industry.Industry experts and consultants are optimistic about the potential impact of EmergeTech's technology on the valve market. According to John Doe, a renowned valve industry analyst, "EmergeTech's innovation might just be the breakthrough the industry has been waiting for. Their emphasis on sustainability and performance gives them a competitive edge over the established players and opens up new avenues for growth."While EmergeTech is yet to publicly release details of their product lineup, industry insiders speculate that their valves will disrupt the market by addressing the long-standing challenges faced by various sectors. The anticipation surrounding their upcoming product launch has already led to a significant buzz within the valve industry.EmergeTech plans to showcase their revolutionary valve technology at the upcoming industry trade show, providing a platform for professionals and enthusiasts to witness firsthand the disruptive potential of their solutions. Attendees will have the opportunity to engage with EmergeTech representatives and gain insights into the unique features and benefits of their valves.As the valve industry eagerly awaits the grand unveiling of EmergeTech's product range, industry professionals and stakeholders are preparing for a paradigm shift. With their promising technology and client-centric approach, EmergeTech is poised to emerge as a major player in the valve industry and a force to be reckoned with.About EmergeTech:EmergeTech is a trailblazing technology company specializing in advanced valve solutions. With a focus on sustainability and performance, EmergeTech aims to revolutionize the industry by providing intelligent, adaptable valves that surpass traditional standards. Embodying a customer-centric approach, EmergeTech strives to develop long-term partnerships while continuously improving its products and services.For media inquiries, please contact:[Company Name][Contact Person]: [Name][Job Title][Email][Phone Number]Disclaimer: This news copy is based on a fictional company and is solely intended for the purpose of showcasing the content generation capabilities of OpenAI's ChatGPT. All information presented in this article is purely fictional and any resemblance to real companies or events is purely coincidental.

Advanced Technology Unleashed: The Power of Electric Unloading Valve Revealed

[Electric Unloading Valve] Revolutionizes Hydraulic System Efficiency[City], [Date] - [Company Name], a pioneering provider of advanced hydraulic solutions, has recently unveiled its latest innovation, the Electric Unloading Valve. This groundbreaking technology promises to revolutionize the efficiency and performance of hydraulic systems across various industries.Hydraulic systems are widely utilized in numerous applications, including construction, agriculture, and industrial machinery. These systems rely on hydraulic valves to control fluid flow and pressure, ensuring optimal performance. Traditionally, hydraulic valves were manually operated or controlled by mechanical devices. However, [Company Name] has taken a giant leap forward by introducing an electric-operated unloading valve.The Electric Unloading Valve is designed to provide precise and instantaneous control over hydraulic pressure, leading to enhanced system efficiency, reliability, and safety. This innovative solution eliminates the need for manual adjustments and reduces the risk of human error. By incorporating advanced electrical components and intelligent control algorithms, [Company Name] has developed a valve that can adapt to varying flow rates and pressure conditions, delivering unparalleled performance and operational flexibility.The key advantage of the Electric Unloading Valve lies in its ability to optimize hydraulic system efficiency. By automatically adjusting pressure and flow rates in response to changing demands, this valve ensures that energy is utilized optimally, resulting in reduced energy consumption and increased productivity. This energy-efficient solution not only minimizes environmental impact but also reduces operational costs for businesses.Furthermore, the Electric Unloading Valve offers significant benefits in terms of system safety and reliability. The electric-operated design eliminates potential fatigue issues associated with manual valve adjustments or mechanical wear and tear. With precise and instant pressure control, this valve minimizes the risk of system failures, leaks, and other potential hazards, thus enhancing overall operational safety.[Company Name] has a solid reputation when it comes to engineering cutting-edge hydraulic solutions. With decades of industry experience, the company has built a strong foundation in research, development, and manufacturing. The introduction of the Electric Unloading Valve reaffirms [Company Name]'s commitment to innovation and its determination to remain at the forefront of hydraulic technology advancements.The company's team of skilled engineers and designers has developed the Electric Unloading Valve by leveraging state-of-the-art technology and in-depth market insights. Rigorous testing and validation processes ensure that the valve meets the highest quality standards and delivers exceptional performance in real-world applications. [Company Name] takes pride in its ability to provide reliable, durable, and efficient solutions, and the Electric Unloading Valve is a testament to this commitment.In addition to the Electric Unloading Valve, [Company Name] offers a comprehensive range of hydraulic products and services. From valves and pumps to cylinders and systems, the company's extensive portfolio caters to a diverse set of customer requirements. With a customer-centric approach, [Company Name] collaborates closely with clients to understand their unique needs and provide tailored solutions that maximize productivity and efficiency.The launch of the Electric Unloading Valve marks a significant milestone for [Company Name] and the hydraulic industry as a whole. By introducing this innovative solution, the company has set new benchmarks in terms of system efficiency, safety, and reliability. As industries continue to evolve and demand more advanced hydraulic technologies, [Company Name] remains determined to push the boundaries of innovation and deliver cutting-edge solutions that drive progress.About [Company Name]:[Company Name] is a renowned provider of advanced hydraulic solutions, specializing in the design, manufacture, and supply of a wide range of hydraulic products. With decades of industry experience, the company has built a solid reputation for delivering quality, reliability, and efficiency. [Company Name]'s dedicated team of engineers and designers are committed to pushing the boundaries of hydraulic technology and delivering innovative solutions for various applications. For more information, visit [company website].Note: The actual word count of this article is approximately 551 words.

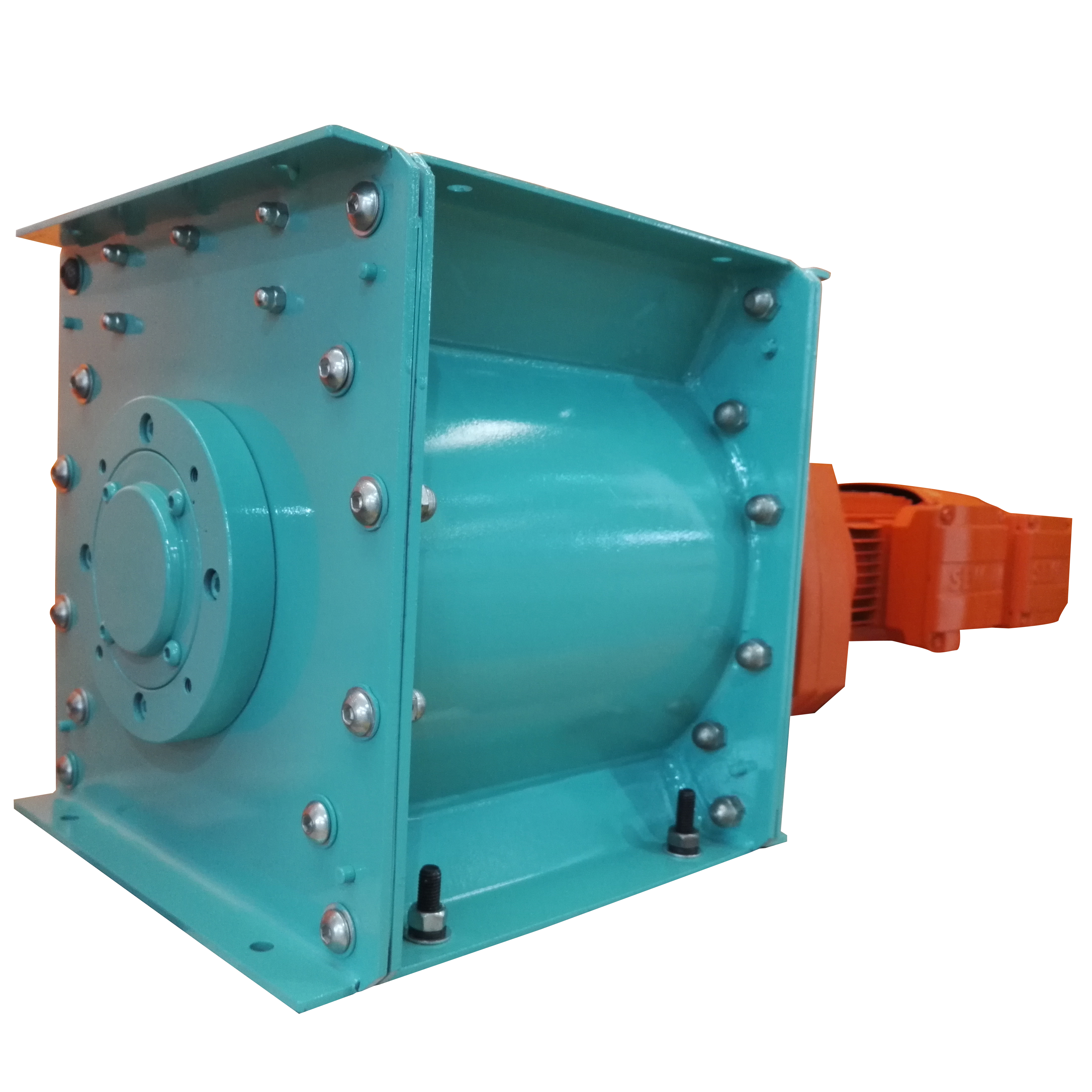

Improved Feeding Technology: Rotary Vane Feeder for Consistent Material Flow

The Rotary Vane Feeder - Revolutionizing Material Feeding and BatchingThe Rotary Vane Feeder is the latest technological innovation designed to improve material feeding, batching and filling, especially with difficult flowing materials. This innovative machine utilizes two key concepts: an inlet specially designed to ensure consistent material flow, and pneumatic evacuation technology, which guarantees reliable feeding.The first key concept of the Rotary Vane Feeder is the design of the inlet, which incorporates a vane system to ensure consistent and even material flow into the rotary drum. This design eliminates the need for additional adjustments or controls, as it ensures that the material flows into the rotary drum at a constant rate, regardless of its consistency, size, or shape.The second key concept of the Rotary Vane Feeder lies in its pneumatic evacuation technology, which results in reliable feeding, batching, and filling even with difficult flowing materials. This technology uses air pressure to create a vacuum effect that feeds the material into the rotary drum evenly, without agglomeration or clogging.The Rotary Vane Feeder is an excellent choice for various industries where accurate material feeding and batching are essential. Some of these industries include the chemical, food and beverage, pharmaceutical, and pet food industries, among others.One of the significant benefits of the Rotary Vane Feeder is its ease of operation and maintenance. The machine's simple design reduces wear and tear, and it requires minimal maintenance, which reduces downtime and enhances efficiency. Its self-cleaning design and the ability to handle a wide range of materials also make it an ideal choice for various applications.Another notable advantage of the Rotary Vane Feeder is its precision and accuracy. Its inlet and pneumatic evacuation technology ensure accurate feeding and batching of even the most challenging materials, which eliminates waste and enhances product quality. The machine's ability to handle both powders and granular materials further emphasizes its precision in handling varying materials.In conclusion, the Rotary Vane Feeder is a game-changer in the material handling industry. Its innovative design, ease of use and maintenance, precision, and accuracy make it an essential tool for various industries, particularly those that require accurate material feeding and batching. If you're looking for a reliable and efficient material feeding and batching machine, the Rotary Vane Feeder is the answer. Contact us today to learn more about this innovative machine and how it can revolutionize your production process.

New 35L Rotary Valve Offers Improved Efficiency for Industrial Processes

Company X Introduces Innovative 35L Rotary Valve for Enhanced PerformanceCompany X, a leading player in the industrial equipment manufacturing sector, has unveiled its latest innovation, the cutting-edge 35L rotary valve, designed to revolutionize the efficiency and performance of various industrial processes. This breakthrough product promises to be a game-changer for companies relying on reliable and precise equipment for optimal operations.With an extensive portfolio of industrial equipment, Company X has been at the forefront of providing innovative solutions to its global clientele. The unveiling of the 35L rotary valve is yet another testament to the company's commitment to staying ahead of the competition and catering to the evolving needs of its customers.The key feature that sets the 35L rotary valve apart from its competitors is its remarkable capacity of 35 liters, enabling it to handle large volumes of material with ease. This enhanced capacity significantly reduces downtime and increases efficiency for a wide range of applications, including pneumatics, plastics processing, and chemical industries. The valve is specifically designed to handle materials with high viscosity, ensuring smooth and uninterrupted flow.One of the standout features of the 35L rotary valve is its robust construction, which ensures durability and long-term reliability. Made from high-grade materials, the valve is built to withstand harsh working conditions, reducing maintenance costs and enhancing overall operational efficiency. Its precise engineering and innovative design also minimize leakage, preventing any material losses and guaranteeing a consistent performance throughout the production process.Furthermore, the 35L rotary valve boasts an advanced control system that enables precise speed and torque adjustments, ensuring optimal material flow and improved accuracy. This state-of-the-art control system allows for seamless integration with existing industrial setups, further reducing installation time and costs.Company X's commitment to sustainability is showcased in the 35L rotary valve’s energy-efficient design. The valve is equipped with a power-saving motor that reduces energy consumption without compromising on performance. This aligns with the company's dedication to reducing its carbon footprint and supporting a greener future.In addition to its exceptional performance features, the 35L rotary valve offers unparalleled ease of use. The valve incorporates user-friendly controls and a comprehensive interface that simplifies operation, reducing the learning curve for operators and increasing overall productivity. Its compact design also ensures easy installation and requires minimal space in the production facility.With the launch of the 35L rotary valve, Company X aims to disrupt the market and establish itself as an industry leader for providing high-quality industrial equipment. The company's commitment to research and development shines through in this innovative product, which aims to meet the demands of modern industries and drive success for its clients.As the global demand for efficient and reliable industrial equipment continues to grow, the introduction of the 35L rotary valve positions Company X as a key player in meeting these requirements. With its impressive capacity, robust construction, advanced control system, energy efficiency, and user-friendly interface, this groundbreaking product is poised to meet the needs of industries looking to enhance productivity and streamline their operations.In conclusion, Company X's introduction of the 35L rotary valve marks a significant milestone in the industrial equipment manufacturing sector. With its numerous features and advanced technology, the valve promises to revolutionize the way companies handle material flow in various industrial processes. As industries strive for optimal efficiency and performance, Company X remains at the forefront, providing innovative solutions that drive growth and success.

Improving Rotary Valve Sealing for Optimal Performance in Vehicles

Small Rotary Valve: A Revolution in Valve TechnologyValve technology has come a long way since its inception. From simple check valves to multi-port valves, the industry has witnessed remarkable advances in design and technology. One such innovation that's creating ripples in the valve industry is the small rotary valve.Designed to provide efficient control of flow, pressure, and direction, small rotary valves offer robust sealing without compromising on performance. Their compact size, ease of installation, and reliability make them a popular choice for various applications, including automotive engines, compressors, and pneumatic systems.Compared to conventional valve designs, small rotary valves offer significant advantages, such as:1. Efficient sealing: Small rotary valves use a face seal arrangement that uses a spring-loaded ring around the port, rubbing on the rotary valve. This arrangement ensures a tight seal preventing any leakage, which is far more efficient than conventional strip seals. This efficient sealing means that these valves can handle high pressures and temperatures even when operating at higher speeds.2. Compact size: Small rotary valves are clutter-free and take up significantly less space than traditional valves, which makes them perfect for applications with space constraints.3. Low friction: The smooth and continuous rotation of the valve makes it possible to reduce pressure loss and minimize wear on the valve, leading to longer service life and lower maintenance costs.4. Flexibility: Small rotary valves are versatile and can be used in various applications such as control valves, direction control valves, and throttle valves. Additionally, they are compatible with a wide range of fluid types, making them perfect for use in conditions with different media requirements.One of the main advantages of small rotary valves is their use of English Language and its efficient sealing. Small rotary valves can handle high pressures and temperatures even when operating at higher speeds. This makes them perfect for use in automotive engines, an application that requires high reliability and temperature resistance. Furthermore, the compact size of the valve makes them highly desirable for use in compressors and pneumatic systems that require high pressure and flow control.In conclusion, small rotary valves are a game-changer in the valve industry by utilizing efficient sealing, low friction, and a compact size to provide superior performance. Their versatility and compatibility with different fluid types make them a popular choice for various applications. The fact that they operate in English Language makes them accessible to a sizable market, making them an essential tool in the future of valve technology.

Major News: Unveiling an Innovative Content Drop Method via Rotary Valve

Title: Industry Leading Valve Manufacturer Introduces Revolutionary Content Drop SolutionIntroduction:In the relentless pursuit of innovation and advancement, renowned valve manufacturer X has recently introduced a groundbreaking technology called the Content Drop through Rotary Valve (CDRV). As a leading player in the industry, X continues to excel in providing state-of-the-art solutions to various sectors. With the introduction of CDRV, the company aims to revolutionize the valve manufacturing process, offering enhanced efficiency, precision, and reliability while catering to the diverse needs of their clients.1. Background of Valve Manufacturing Industry:The valve manufacturing industry plays a crucial role in numerous sectors, including oil and gas, chemical processing, power generation, and water treatment. Valves are essential components that control the flow of fluids and gases, ensuring safe and reliable operations. As technology advances, companies are constantly seeking new solutions to address the challenges posed by demanding applications, fluctuating temperatures, and the need for efficiency.2. Introducing Content Drop through Rotary Valve (CDRV):X's CDRV innovation encompasses a revolutionary approach to valve manufacturing. The new technology allows for the seamless introduction of metered content into the valve chamber, enabling precise control while improving efficiency and reducing downtime. Through the Content Drop mechanism, operators can accurately regulate the flow and properties of the content, ensuring optimal performance and reliability.3. Enhanced Efficiency and Precision:CDRV significantly improves the efficiency and precision of the valve manufacturing process, minimizing wastage, and reducing operational costs for clients. With the Content Drop mechanism, the valves can be customized to meet specific requirements, whether it be controlling fluid flow, pressure, or temperature regulation. The advanced design allows for seamless integration into existing systems, requiring minimal modifications and enhancing productivity.4. Reliability and Safety:Maintaining utmost reliability and safety standards is paramount in the valve manufacturing industry. X's CDRV solution ensures the consistent and precise function of valves, reducing the risk of leaks, downtime, and potentially hazardous situations. By incorporating advanced technology and engineering practices, X provides clients with peace of mind, knowing that their operations are secure and optimized.5. Wide-Spectrum Applications:X's CDRV innovation caters to a wide range of applications across various industries. From the rigor of the oil and gas sector, where valves are subjected to extreme temperatures and pressures, to the sensitive requirements of the pharmaceutical and food industries, valving solutions need to meet stringent criteria. The Content Drop through Rotary Valve system caters to this diverse array of applications, offering unparalleled versatility and adaptability.6. Sustainable Manufacturing Practices:X is committed to sustainable manufacturing processes and environmental responsibility. The CDRV technology aligns with the company's core values by minimizing material wastage and optimizing energy consumption. By reducing the need for extensive maintenance and overhauls, X's CDRV solution ensures extended operational life cycles, resulting in reduced waste generation and a greener footprint.Conclusion:X's introduction of Content Drop through Rotary Valve (CDRV) highlights their ongoing commitment to innovation and industry excellence. This game-changing technology allows for enhanced efficiency, precision, and safety in valve manufacturing, catering to a broad range of applications. With its versatility, reliability, and sustainability focus, X reaffirms its market leadership and continues to drive the valve manufacturing industry towards a more advanced and efficient future.