Essential Guide: Exploring the Purpose and Functionality of Butterfly Valves

[Company Name] Develops Innovative Air Butterfly Valve for Enhanced Performance[City Name, Date] - [Company Name], a leading provider of industrial valves and control solutions, is proud to introduce its latest innovation, the Air Butterfly Valve. This revolutionary product aims to significantly enhance valve performance and efficiency in various industrial applications.The Air Butterfly Valve developed by [Company Name] utilizes cutting-edge technology to deliver superior control and monitoring capabilities. The valve is specifically designed to regulate the flow of air, gases, and certain fluids in pipelines. Its unique construction and features make it an ideal choice for industries such as oil and gas, water treatment, power generation, and chemical processing.One of the standout characteristics of the Air Butterfly Valve is its exceptional performance, which translates into improved productivity and reduced operational costs for businesses. The valve is engineered to provide accurate and precise control over flow rates, ensuring optimal process performance. This level of control enables companies to achieve desired outcomes more efficiently, leading to enhanced overall productivity.Furthermore, the Air Butterfly Valve's advanced design ensures minimal pressure drop across the valve, resulting in energy savings and reduced environmental impact. By effectively managing airflow and reducing turbulence, the valve helps companies meet sustainability goals and comply with regulatory requirements.The valve's durability and reliability are also worth mentioning. Manufactured using high-quality materials, the Air Butterfly Valve demonstrates exceptional resistance to wear, corrosion, and extreme temperatures. This durability translates into longer service life and reduced maintenance costs, contributing to overall cost savings for businesses.In addition to its successful product development, [Company Name] boasts an impressive track record in the valve industry. Established in [Year], the company has been a reliable partner for countless customers worldwide, catering to their diverse valve needs. With a commitment to continuous improvement and customer satisfaction, [Company Name] has become a trusted brand known for its innovative solutions and exceptional service."We are thrilled to introduce the Air Butterfly Valve to our esteemed customers," said [Spokesperson Name], CEO of [Company Name]. "This product is a testament to our dedication to providing cutting-edge solutions that address our customers' needs. With its superior performance and durability, we believe the Air Butterfly Valve will deliver substantial benefits to industries across the globe."[Company Name] has a highly skilled team of engineers and technical professionals who work tirelessly to develop and improve innovative valve solutions. The company's state-of-the-art manufacturing facilities ensure the highest quality standards are met throughout the production process. With a customer-centric approach, [Company Name] offers comprehensive support, including installation services, maintenance, and technical consultations.As a forward-thinking company, [Company Name] actively seeks partnerships and collaborations with industry leaders and organizations to further advance valve technology. By staying at the forefront of technological advancements and industry trends, [Company Name] aims to continue delivering innovative solutions that drive progress and create value for its customers.#####About [Company Name]:[Company Name] is a globally recognized provider of high-quality valves and control solutions. With [number] years of experience, the company has established itself as an industry leader, renowned for its innovative approach and commitment to customer satisfaction. [Company Name] serves a wide range of industries, including oil and gas, water treatment, power generation, and chemical processing. For more information, please visit [website URL].Media Contact:[Media Contact Name][Contact Job Title][Company Name][Phone Number][Email Address]

Read More

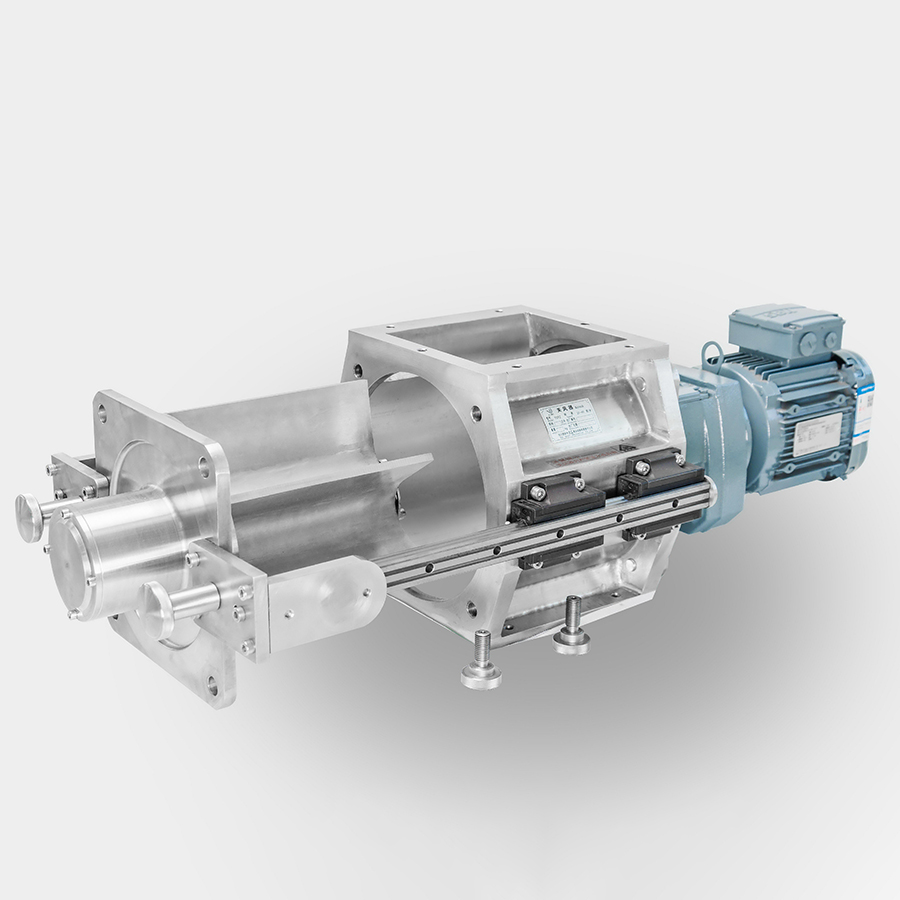

Top Manufacturers of Rotary Valves and Drop Through Air Locks in China

China Drop-Thru Rotary Valve: Revolutionizing Industrial ProcessesIn recent years, China has emerged as a leading manufacturer and supplier of rotary valves, hydraulic rotary valves, and drop-through rotary airlocks. These essential components play a crucial role in various industries, facilitating the efficient and seamless movement of materials. This blog will delve into the significance of China's drop-thru rotary valves, their applications across industries, and the benefits they offer.Drop-thru rotary valves are precision-engineered devices designed to regulate the flow of powdered or granular materials in pneumatic conveying systems. These valves are commonly used in industrial processes, such as cement production, chemical processing, food processing, and pharmaceutical manufacturing. Their diverse applications make them a vital component in ensuring the efficiency, safety, and productivity of these industries.One of the primary advantages of drop-thru rotary valves is their ability to effectively control the flow of materials. As the material flows into the valve's inlet, the rotor revolves, creating a seal between the inlet and outlet. This seal prevents air from escaping and ensures that the conveyed material is directed precisely to its destination. The controlled flow rate prevents material leakage, contamination, and wastage, thereby optimizing the overall production process.Furthermore, drop-thru rotary valves act as an integral part of pneumatic conveying systems. These systems enable the transfer of materials from one location to another using the power of compressed air. By incorporating drop-thru rotary valves into pneumatic conveying systems, industries can significantly enhance the efficiency and effectiveness of their material handling processes. The valves facilitate the regulated discharge of materials into pipelines, ensuring a continuous flow and preventing clogs or blockages.In the cement production industry, drop-thru rotary valves are extensively used in the handling of cementitious materials. These valves serve a critical function in the kiln feed, ensuring the accurate feeding and distribution of raw materials into the rotary kiln. The precise control offered by drop-thru rotary valves is vital in maintaining the appropriate mix proportions and preventing fluctuations in the overall composition of the cement mixture. This guarantees the high-quality output desired in cement production.The chemical processing industry also relies heavily on drop-thru rotary valves for the efficient and safe handling of various chemicals. With the capability to handle corrosive, hazardous, or abrasive materials, these valves play a crucial role in preventing leaks or spillages that could pose a danger to workers or equipment. Whether it is the transfer of aggressive solvents or the dosing of chemicals into reactors, drop-thru rotary valves ensure the controlled flow and accurate dosing required for seamless chemical processing.In food processing, drop-thru rotary valves are widely used in applications such as bulk handling, batch weighing, and material feeding. The valves are designed to meet strict hygienic standards, making them suitable for use in environments where cleanliness is paramount. As food products move through processing equipment, the valves provide airtight seals, preventing any contamination from external elements, such as dust or pollutants. This ensures the preservation of product quality and adherence to strict food safety regulations.The pharmaceutical industry is yet another sector that benefits from the utilization of drop-thru rotary valves. These valves are commonly employed in processes such as tablet manufacturing, powder handling, and capsule filling. Pharmaceutical products demand the highest level of cleanliness, precision, and accuracy. Drop-thru rotary valves meet these requirements by facilitating the controlled discharge of exact quantities of powders or granules into the processing equipment. This precise metering prevents overfilling or underfilling, maintaining the integrity, efficacy, and consistency of the final products.China's manufacturing prowess in drop-thru rotary valves has solidified its position as a leading supplier globally. With an extensive network of manufacturers and suppliers, China offers a wide range of options in terms of design, materials, sizes, and functionalities. Additionally, Chinese manufacturers strive to improve the quality and performance of their products while remaining competitive in terms of cost. This has positioned China as a preferred choice for businesses seeking reliable and cost-effective solutions in the form of drop-thru rotary valves.To sum up, drop-thru rotary valves have significantly revolutionized industrial processes across a range of sectors. From cement production to chemical processing, from food handling to pharmaceutical manufacturing, these valves offer precise control, improved efficiency, and enhanced safety. China, with its leading manufacturers and suppliers, has played a pivotal role in the development and supply of these vital components. As industries continue to seek effective solutions for material handling, drop-thru rotary valves from China will undoubtedly remain an indispensable asset.

Read More

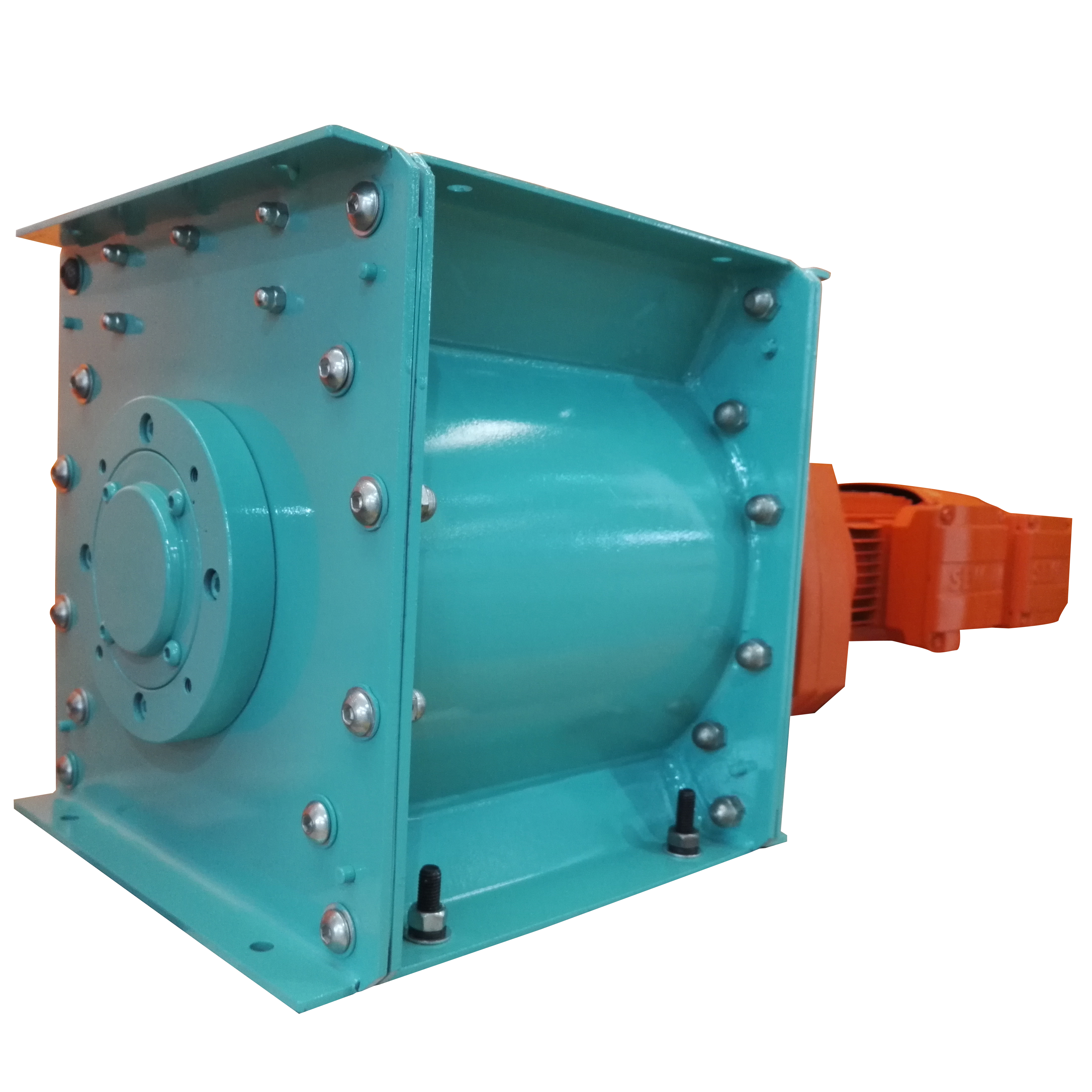

Discover the Latest Advancements in Rotary Feeder Technology

Title: High-Performance Rotary Feeder Innovates Material Handling ProcessesIntroduction:In a constant quest for superior material handling solutions, companies across industries rely heavily on innovative technology to enhance productivity and efficiency. One such groundbreaking development is the recently launched Valve Rotary Feeder, designed to revolutionize material handling processes. Developed by a prominent engineering firm, this state-of-the-art rotary feeder seamlessly combines exceptional performance with precision, ensuring seamless material flow and optimal operations.Body:1. Transition to discussing the Valve Rotary Feeder:The Valve Rotary Feeder showcases a range of cutting-edge features that set it apart from conventional material handling systems. Built with the latest advancements in engineering technology, this comprehensive solution has the potential to redefine material handling across various sectors.2. Efficient Material Handling:The Valve Rotary Feeder boasts an unmatched ability to handle bulk materials with the utmost precision. Its high-performance operation drastically reduces issues related to contamination, spillages, and product loss during transfer. This innovative technology ensures continuous, uniform material flow, thus streamlining downstream processes and improving overall productivity.3. Reliable and Durable Construction:Engineered using top-grade materials, the Valve Rotary Feeder exhibits remarkable strength and durability, guaranteeing a long operational life for companies investing in this solution. Its resilient construction also ensures resistance to various abrasive materials and harsh working conditions, making it an ideal choice for industries handling challenging materials.4. Precision Control:With the incorporation of advanced control mechanisms, the Valve Rotary Feeder enables precise material dosing and flow control. This feature facilitates accurate material distribution and ensures optimal usage, significantly reducing waste and associated costs. The feeder's ability to handle a wide range of materials of varying textures and characteristics enhances its adaptability, making it suitable for diverse industry applications.5. Easy Maintenance and Enhanced Safety:Designed with user convenience in mind, the Valve Rotary Feeder offers hassle-free maintenance procedures while adhering to strict safety standards. Its modular design allows for quick and easy repairs or replacements, reducing downtime and maximizing productivity. Furthermore, the incorporation of safety features, such as emergency shut-off mechanisms and enhanced sealing, ensures the well-being of operators and prevents potential accidents.6. Versatile Applications:The Valve Rotary Feeder finds vast applications in numerous sectors, including but not limited to cement, mining, food processing, pharmaceuticals, and chemicals. Its ability to handle various materials, such as powders, granules, pellets, and abrasive substances, makes it an indispensable asset for industries prioritizing seamless material handling with minimal downtime.7. Environmental Considerations:Keeping sustainability in mind, the Valve Rotary Feeder minimizes the risk of emissions and dust, thereby reducing environmental impact. Its efficient material handling and precise control contribute to responsible resource utilization, ensuring companies meet stringent environmental regulations without compromising on operational efficiency.8. Industry Impact and Potential:The introduction of the Valve Rotary Feeder holds significant potential for revolutionizing material handling practices across industries. Its ability to automate processes, optimize efficiency, and minimize product loss positions it as a game-changer in the field of material handling. As a result, companies investing in this advanced solution can yield higher productivity, reduce costs, and gain a competitive edge in the market.Conclusion:In conclusion, the Valve Rotary Feeder represents a breakthrough in material handling technology, offering unparalleled precision, efficiency, and reliability. With its innovative design, the feeder addresses longstanding challenges in material flow, ensuring optimal operational performance across various industries. By investing in this state-of-the-art solution, companies can streamline their processes, increase productivity, and stay at the forefront of a rapidly evolving market.

Read More

High Pressure Plug Valve: Everything You Need to Know

High Pressure Plug Valve is a vital component in the oil and gas industry, playing a crucial role in controlling the flow of fluids in high-pressure applications. The valve is specifically designed to handle extreme pressure environments and is commonly used in pipelines, production facilities, and drilling operations.One of the leading manufacturers of High Pressure Plug Valve is the {Brand Name}, a renowned company with a rich history of providing high-quality industrial valves and solutions. With over 50 years of experience in the industry, {Brand Name} has established a strong reputation for delivering reliable and innovative products that meet the stringent demands of the oil and gas sector.The High Pressure Plug Valve offered by {Brand Name} is designed to meet the highest standards of performance, reliability, and safety. The valve is constructed using premium materials such as stainless steel and high-alloy steels, ensuring exceptional durability and resistance to corrosion in harsh operating conditions. In addition, {Brand Name} utilizes advanced manufacturing processes and state-of-the-art technology to produce High Pressure Plug Valves that meet or exceed industry standards.One of the key features of {Brand Name}'s High Pressure Plug Valve is its ability to withstand extreme pressure and temperature variations. The valve is engineered to provide a tight seal even under high-pressure conditions, making it an ideal choice for critical applications where leakage is not an option. Furthermore, the valve is designed for ease of operation, with smooth and precise actuation mechanisms that allow for quick and reliable flow control.In addition to its outstanding performance capabilities, {Brand Name}'s High Pressure Plug Valve is also known for its low maintenance requirements and long service life. The company's commitment to quality and reliability ensures that their valves are capable of withstanding the rigors of the oil and gas industry, reducing downtime and minimizing the need for frequent repairs or replacements.{Brand Name} also offers a range of customization options for its High Pressure Plug Valve, allowing customers to tailor the valves to their specific requirements. Whether it's a particular size, pressure rating, or material specification, {Brand Name} has the capability to design and manufacture bespoke valves that meet the unique needs of each customer.Furthermore, {Brand Name} provides comprehensive technical support and after-sales services for its High Pressure Plug Valve, ensuring that customers have access to expert assistance whenever they need it. This commitment to customer satisfaction has earned {Brand Name} a loyal base of clients who trust in the quality and reliability of their products.In conclusion, {Brand Name}'s High Pressure Plug Valve is a testament to the company's dedication to delivering superior valve solutions for the oil and gas industry. With its focus on quality, performance, and customer satisfaction, {Brand Name} continues to be a trusted partner for companies seeking high-quality valves for their most demanding applications.

Read More

Benefits and Applications of Pneumatic Cylinders for Various Industries

Pneumatic Cylinder Boosts Industrial EfficiencyIn the fast-paced world of industrial automation, choosing the right pneumatic component can make or break an operation. This is where (name of company) comes in, offering a comprehensive range of high-quality pneumatic solutions, including a top-of-the-line pneumatic cylinder.What is a pneumatic cylinder? Simply put, this device converts compressed air into mechanical motion. It is a crucial component for a wide range of manufacturing, assembly, and packaging applications, from conveyor systems to pick-and-place machines.The (name of company) pneumatic cylinder boasts superior performance and durability, making it an ideal choice for demanding industrial environments. With a high-precision design, tight tolerances, and high-quality materials, this cylinder can operate at high speeds and in extreme temperatures, while maintaining accuracy and reliability.One of the key advantages of this pneumatic cylinder is its low-friction operation. This means that it can move smoothly and quickly, with minimal wear and tear on the components. This not only extends the lifespan of the cylinder but also reduces maintenance costs and downtime.Another benefit is its versatility. The (name of company) pneumatic cylinder comes in a range of sizes, styles, and mounting options, making it easy to integrate into any existing system or design. It is also customizable, with options for different seals, ports, and functionality.The pneumatic cylinder is just one of the many high-quality pneumatic components offered by (name of company). Their extensive product line includes valves, actuators, fittings, and accessories, all designed to meet the needs of industrial automation professionals.But the company's commitment to quality goes beyond just their products. They also offer exceptional customer service and technical support, ensuring that their clients have all the information and assistance they need to make the most of their pneumatic components.In addition, the company focuses on sustainability, designing products that are energy-efficient and environmentally friendly. Their pneumatic cylinders, for example, consume less air than traditional models, reducing energy costs and carbon emissions.Overall, the (name of company) pneumatic cylinder is a top-performing, versatile, and sustainable choice for industrial automation professionals. With a commitment to quality and customer satisfaction, (name of company) is a reliable partner for businesses seeking to optimize their operations.

Read More

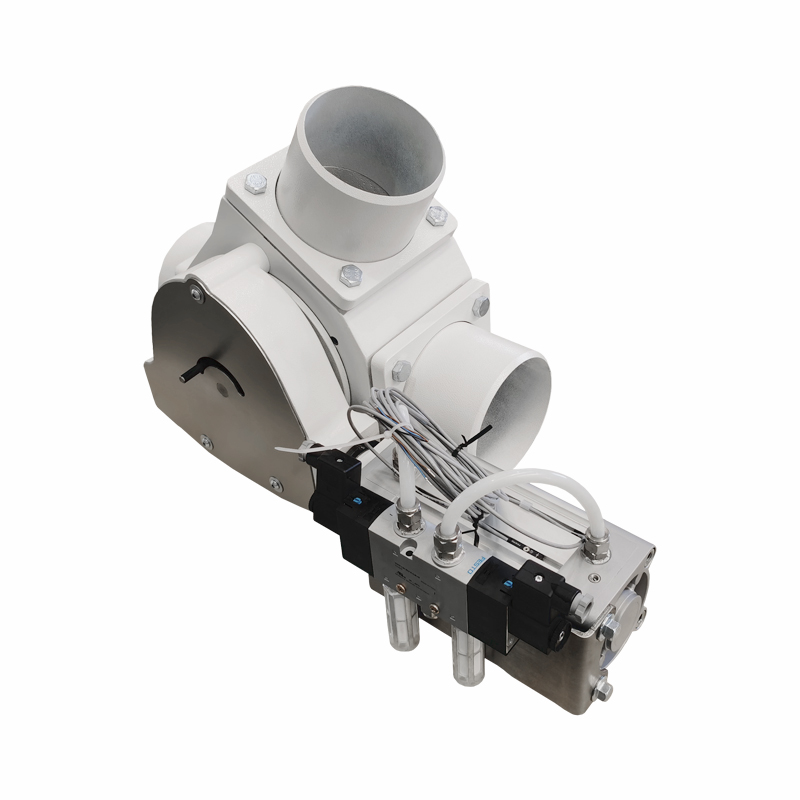

Introducing the Innovative Pneumatic Diverter Technology for Industrial Applications

Pneumatic Diverter a Key Solution for Material Handling in Various IndustriesIn the world of material handling and processing, having the right equipment to efficiently move and divert materials is crucial for optimizing production and reducing waste. One key solution that has been gaining widespread popularity in various industries is the Pneumatic Diverter. This innovative piece of equipment, which is manufactured and supplied by leading industrial equipment supplier {}, has proven to be a game-changer for many businesses looking to streamline their material handling processes.The Pneumatic Diverter is a versatile and reliable system that is capable of diverting materials from one conveying line to another with precision and efficiency. It is commonly used in industries such as mining, construction, food and beverage, pharmaceuticals, and many others where the movement of materials is a critical component of the production process. The ability to seamlessly redirect materials from one process to another without the need for manual intervention has made the Pneumatic Diverter an invaluable tool for companies looking to automate and optimize their material handling operations.One of the key features of the Pneumatic Diverter is its use of pneumatic power to control the movement of materials. This means that the system can be integrated into existing pneumatic conveying systems with ease, making it a cost-effective solution for companies looking to upgrade their material handling capabilities. The use of pneumatic power also ensures that the system operates with precision and reliability, reducing the risk of errors and downtime that can be costly for businesses.Another advantage of the Pneumatic Diverter is its modular design, which allows for easy installation and customization to suit specific production requirements. Whether it's diverting materials at high speeds or handling abrasive and corrosive materials, the Pneumatic Diverter can be tailored to meet the unique needs of different industries. This flexibility has made it a popular choice for businesses looking for a versatile solution that can adapt to changing production demands.In addition to its technical capabilities, the Pneumatic Diverter is also designed with the highest standards of quality and safety in mind. With robust construction and adherence to industry regulations, businesses can trust that the system will operate reliably and safely, reducing the risk of accidents and costly downtime. This commitment to quality and safety has earned the Pneumatic Diverter a reputation as a trusted solution for demanding material handling environments.As a leading industrial equipment supplier, {} has been at the forefront of providing innovative solutions like the Pneumatic Diverter to businesses across various industries. With a commitment to delivering high-quality products and exceptional customer service, {} has established a reputation as a reliable partner for companies looking to enhance their material handling capabilities. The company's team of experts works closely with clients to understand their specific needs and provide tailored solutions that deliver tangible results.The success stories of businesses that have implemented the Pneumatic Diverter speak volumes about its impact on material handling efficiency and productivity. From reducing material waste to improving overall production throughput, the Pneumatic Diverter has proven to be an invaluable asset for businesses looking to stay ahead in today's competitive market.In conclusion, the Pneumatic Diverter has emerged as a key solution for material handling in various industries, offering a combination of precision, reliability, and versatility. With its seamless integration, modular design, and commitment to quality and safety, it is no wonder that businesses across the globe are turning to the Pneumatic Diverter to optimize their material handling processes. As the demand for efficient and cost-effective material handling solutions continues to grow, the Pneumatic Diverter is poised to play a pivotal role in helping businesses meet their production goals and stay competitive in the market.

Read More

Advanced Technology Unleashed: The Power of Electric Unloading Valve Revealed

[Electric Unloading Valve] Revolutionizes Hydraulic System Efficiency[City], [Date] - [Company Name], a pioneering provider of advanced hydraulic solutions, has recently unveiled its latest innovation, the Electric Unloading Valve. This groundbreaking technology promises to revolutionize the efficiency and performance of hydraulic systems across various industries.Hydraulic systems are widely utilized in numerous applications, including construction, agriculture, and industrial machinery. These systems rely on hydraulic valves to control fluid flow and pressure, ensuring optimal performance. Traditionally, hydraulic valves were manually operated or controlled by mechanical devices. However, [Company Name] has taken a giant leap forward by introducing an electric-operated unloading valve.The Electric Unloading Valve is designed to provide precise and instantaneous control over hydraulic pressure, leading to enhanced system efficiency, reliability, and safety. This innovative solution eliminates the need for manual adjustments and reduces the risk of human error. By incorporating advanced electrical components and intelligent control algorithms, [Company Name] has developed a valve that can adapt to varying flow rates and pressure conditions, delivering unparalleled performance and operational flexibility.The key advantage of the Electric Unloading Valve lies in its ability to optimize hydraulic system efficiency. By automatically adjusting pressure and flow rates in response to changing demands, this valve ensures that energy is utilized optimally, resulting in reduced energy consumption and increased productivity. This energy-efficient solution not only minimizes environmental impact but also reduces operational costs for businesses.Furthermore, the Electric Unloading Valve offers significant benefits in terms of system safety and reliability. The electric-operated design eliminates potential fatigue issues associated with manual valve adjustments or mechanical wear and tear. With precise and instant pressure control, this valve minimizes the risk of system failures, leaks, and other potential hazards, thus enhancing overall operational safety.[Company Name] has a solid reputation when it comes to engineering cutting-edge hydraulic solutions. With decades of industry experience, the company has built a strong foundation in research, development, and manufacturing. The introduction of the Electric Unloading Valve reaffirms [Company Name]'s commitment to innovation and its determination to remain at the forefront of hydraulic technology advancements.The company's team of skilled engineers and designers has developed the Electric Unloading Valve by leveraging state-of-the-art technology and in-depth market insights. Rigorous testing and validation processes ensure that the valve meets the highest quality standards and delivers exceptional performance in real-world applications. [Company Name] takes pride in its ability to provide reliable, durable, and efficient solutions, and the Electric Unloading Valve is a testament to this commitment.In addition to the Electric Unloading Valve, [Company Name] offers a comprehensive range of hydraulic products and services. From valves and pumps to cylinders and systems, the company's extensive portfolio caters to a diverse set of customer requirements. With a customer-centric approach, [Company Name] collaborates closely with clients to understand their unique needs and provide tailored solutions that maximize productivity and efficiency.The launch of the Electric Unloading Valve marks a significant milestone for [Company Name] and the hydraulic industry as a whole. By introducing this innovative solution, the company has set new benchmarks in terms of system efficiency, safety, and reliability. As industries continue to evolve and demand more advanced hydraulic technologies, [Company Name] remains determined to push the boundaries of innovation and deliver cutting-edge solutions that drive progress.About [Company Name]:[Company Name] is a renowned provider of advanced hydraulic solutions, specializing in the design, manufacture, and supply of a wide range of hydraulic products. With decades of industry experience, the company has built a solid reputation for delivering quality, reliability, and efficiency. [Company Name]'s dedicated team of engineers and designers are committed to pushing the boundaries of hydraulic technology and delivering innovative solutions for various applications. For more information, visit [company website].Note: The actual word count of this article is approximately 551 words.

Read More

High-Quality and Reliable Gate Valves Available in China

China Gate Valve Company, a leading manufacturer of industrial valves, has recently announced the launch of their new line of innovative gate valves designed to meet the evolving needs of various industries. This move is in line with the company’s commitment to continuously improve their product offerings and provide high-quality solutions to their clients.Established in 1985, China Gate Valve Company has grown to become one of the most trusted names in the valve manufacturing industry. They specialize in producing a wide range of industrial valves including gate valves, globe valves, check valves, ball valves, and butterfly valves. With a strong emphasis on quality and innovation, the company has built a solid reputation for delivering reliable and durable products that meet the stringent requirements of different applications.The newly launched gate valves feature several improvements and enhancements that set them apart from the competition. One of the key highlights is the use of advanced materials and manufacturing techniques, resulting in valves that offer superior performance and extended lifespan. These valves are also designed to handle high-pressure and high-temperature applications, making them suitable for use in demanding industrial environments.In addition to their robust construction, the new gate valves from China Gate Valve Company also boast an improved sealing mechanism that ensures tight shut-off and leak-free operation. This is particularly important for industries where fluid containment and control are critical, such as oil and gas, petrochemical, and power generation.Furthermore, the company has incorporated smart technologies into the design of their gate valves to enable remote monitoring and control. This feature allows for seamless integration with digital systems and automation platforms, offering users greater flexibility and convenience in managing valve operations.The launch of these new gate valves underscores China Gate Valve Company’s commitment to staying at the forefront of valve innovation and meeting the evolving needs of their customers. By investing in research and development, the company aims to address emerging challenges in the industry and deliver solutions that contribute to enhanced efficiency, safety, and performance.“We are excited to introduce our latest line of gate valves that have been engineered to deliver exceptional value to our customers,” said the spokesperson for China Gate Valve Company. “With these new offerings, we are confident that our clients will benefit from the improved functionality, durability, and ease of use that our valves provide. We remain dedicated to upholding the highest standards of quality and reliability in all our products.”China Gate Valve Company’s commitment to excellence extends beyond their product offerings. The company also places great emphasis on customer satisfaction, striving to provide attentive service and support at every stage of the client engagement. Their team of experienced engineers and technical experts are readily available to offer guidance and assistance, ensuring that customers receive the right valves for their specific requirements.As a global leader in the valve manufacturing industry, China Gate Valve Company continues to expand its presence in various markets around the world. Their new line of gate valves is expected to further strengthen their position as a preferred supplier of high-performance valves for a wide range of industrial applications.As industries continue to evolve and demand innovative solutions to their operational needs, China Gate Valve Company remains dedicated to developing cutting-edge valve products that meet and exceed industry standards. With a steadfast commitment to quality, reliability, and customer satisfaction, the company is poised to make a significant impact in the global valve market for years to come.

Read More

End Discharge Formula (Granules, Packets) - Natural TCM Solution for Digestive Issues

TCMzone dimensions have recently introduced a new product, the Wan Dai Tang End Discharge Formula in granules or packets. This product is now available for purchase online and can be shipped within the continental U.S.Orders received before 3 p.m. MST will be shipped out the same day by UPS or USPS. In addition, orders over $200 will be shipped free of charge within the continental U.S. This offer is an added advantage to customers who are willing to purchase more of this product.However, it is to be noted that the returns or exchange of unopened products will be accepted only when it is returned within a period of 30 days from the date of purchase. A restocking fee of 20% will be applied on all returned items. No returns will be accepted after 30 days, and customers must call for a return authorization and include a copy of the invoice for fully credited returns.TCMzone dimensions take great care in filling, checking, and packaging your order. However, on rare occasions, a package may be damaged or lost in transit. If you receive a package that has been damaged, please save the original box or bottle and all its contents and call the customer service immediately for assistance. If you feel your package may have been lost in transit, contact the customer service immediately for tracking assistance.This product is designed to regulate a woman's period, manage period-related symptoms, and reduce heavy bleeding. This formula is made using traditional Chinese herbs that have proven to be effective over centuries. The product can help restore the balance of hormones in the body, promoting better overall health.One of the related products of TCMzone dimensions that can complement the Wan Dai Tang End Discharge Formula is the Women's Vitality Formula. This product is composed of several herbs that can help nourish the body, manage stress and promote better mental health. It also helps ease menstrual-related discomfort and supports overall reproductive health.TCMzone dimensions are committed to providing their customers with high-quality traditional Chinese medicine products that are backed by scientific research. Their products are safe and effective and have no side effects. They remain the go-to option for those interested in natural and holistic health care. In conclusion, Wan Dai Tang End Discharge Formula by TCMzone dimensions is a new product available, delivering effective results to women users suffering from menstruation-related issues. This reputed brand has been delivering health care products for a while and their Women's Vitality Formula is a product that supplements End Discharge Formula, leading to better energy-promoting, better reproductive health.

Read More

Aluminium Die-casting Rotor for Explosion-proof Motor - High-Quality and Reliable

Henan Yongrong Power Technology Co., Ltd, based in China, has recently announced the release of a new product - the Aluminium Die-casting Rotor for Explosion-proof Motor. The rotor is specifically designed for explosion-proof motors and is a welcome addition to the company's range of products.The explosion-proof motor is essential for use in hazardous environments where there are potential dangers associated with explosive gases and dust. Most industries, such as oil and gas, chemical, power generation, and mining, require the use of explosion-proof equipment for worker safety. These motors must be able to operate in an environment where an explosion could potentially occur. The Aluminium Die-casting Rotor is a critical part of the explosion-proof motor as it plays a central role in the motor's functioning.Henan Yongrong Power Technology Co., Ltd has a reputation for producing high-quality rotors that are reliable and long-lasting. The company specializes in manufacturing a wide range of rotors, including aluminium and copper rotors, for use in various industries. The company's rotors have been found to have a high tolerance to harsh conditions, and are therefore suitable for use in hazardous environments.The new Aluminium Die-casting Rotor for Explosion-proof Motor is made using a high-pressure die-casting technique, ensuring that the rotor's quality is consistent and reliable. The die-casting process ensures that the rotor has a high strength-to-weight ratio, making it ideal for use in explosion-proof motors, where the weight of the rotor can impact the motor's performance.Aluminium is a popular material for rotor manufacture because it is lightweight, easy to manufacture, and has good thermal conductivity properties. The thermal conductivity of aluminium allows for better heat dissipation, which is necessary in high-performance motors.The Aluminium Die-casting Rotor for Explosion-proof Motor also features an anti-explosion design, ensuring that the motor remains safe even when an explosion occurs. The rotor is designed to withstand an explosion, ensuring that motor damage is minimal, and that the motor can continue to function even in hazardous environments.As an industry leader in the manufacture of rotors, Henan Yongrong Power Technology Co., Ltd, is known for providing quality products that meet customer needs. The Aluminium Die-casting Rotor for Explosion-proof Motor is yet another example of the company's commitment to meeting industry requirements.In conclusion, the release of the Aluminium Die-casting Rotor for Explosion-proof Motor by Henan Yongrong Power Technology Co., Ltd is a welcome addition to the company's range of products. The rotor's high strength-to-weight ratio, anti-explosion design, and thermal conductivity properties make it ideal for use in hazardous environments. The company's reputation for producing reliable and high-quality rotors ensures that the product will meet industry needs and provide customers with a reliable product. With this new release, Henan Yongrong Power Technology Co., Ltd cements its position as a leader in the rotor manufacturing industry.

Read More