The Latest Updates on Pneumatic Fittings: Essential Information You Need to Know

By:Admin

The global pneumatics industry has witnessed a significant rise in demand for high-quality pneumatic fittings due to their crucial role in various applications. One of the leading companies in this domain, {{brand name}}, has emerged as a trailblazer in developing and manufacturing state-of-the-art pneumatic fittings that have revolutionized the industry. With an unwavering commitment to excellence coupled with cutting-edge technology, {{brand name}} continues to set new benchmarks in terms of product quality and customer satisfaction.

Established with the vision of providing innovative solutions that enhance operational efficiency, {{brand name}} has not only met customer expectations but also exceeded them. The company's foundation is built on strong principles of research, development, and continuous improvement, making it an industry leader. With a diverse product range catering to different industries, {{brand name}} stands out as a trusted partner for a wide array of businesses globally.

At the core of its success lies {{brand name}}'s relentless pursuit of excellence in engineering. The company's team of expert engineers and technicians consistently work to design and produce pioneering pneumatic fittings that deliver exceptional performance, reliability, and durability. By integrating advanced materials and cutting-edge manufacturing processes, {{brand name}} ensures that its products meet the highest quality standards set by the industry.

In addition to product quality, {{brand name}} also places great emphasis on understanding and meeting the unique requirements of its customers. The company's dedicated research and development team works closely with customers to develop custom solutions that address their specific needs, whether it be in terms of dimensions, materials, or specific performance characteristics. This tailored approach has helped {{brand name}} forge long-term partnerships with its customers and establish itself as a trusted name in the pneumatics industry.

One of the key distinguishing features of {{brand name}}'s pneumatic fittings is their versatility. Whether it is for compressed air systems, pneumatic tools, or automation equipment, these fittings seamlessly integrate and perform optimally across various applications. The company's extensive product portfolio includes a wide range of fittings such as push-in fittings, quick-connect couplers, flow control valves, and air blow guns, amongst others. Each product is meticulously designed and rigorously tested to deliver outstanding performance in demanding environments and conditions.

Furthermore, {{brand name}} goes above and beyond conventional standards by incorporating innovative features into its pneumatic fittings. For example, the company's push-in fittings are equipped with secure locking mechanisms that provide a leak-free connection and prevent accidental disconnections. This ensures a safe and efficient working environment, minimizing downtime and improving productivity. Additionally, {{brand name}}'s flow control valves offer precise control over air flow to regulate speed and pressure, enhancing the overall efficiency of pneumatically-operated systems.

While {{brand name}} prides itself on its product excellence, the company's dedication to sustainability is equally noteworthy. Recognizing the importance of environmental conservation, {{brand name}} implements eco-friendly manufacturing practices and utilizes recyclable materials. By reducing waste generation and energy consumption, the company strives to minimize its ecological footprint and contribute to a greener future.

In conclusion, {{brand name}} has become synonymous with innovation and reliability in the field of pneumatic fittings. Through an unwavering commitment to excellence in engineering, understanding customer needs, and embracing sustainable practices, the company has set new industry standards. As the demand for high-quality pneumatic fittings continues to rise in various sectors, {{brand name}} remains poised to lead the way with its cutting-edge solutions that redefine performance and efficiency.

Company News & Blog

Effortlessly Maintain Your Cat's Hygiene with Self-Cleaning Litter Options

Keeping a pet at home is a wonderful and enjoyable experience, especially when you have a furry companion like a cat. However, the task of keeping a clean and hygienic environment for your cat can be quite tedious, especially when it comes to cleaning the litter box. Thankfully, with advancements in technology, self-cleaning cat litter boxes have become widely available, helping cat owners to save time and effort.Self-cleaning litter boxes are designed to make the task of cleaning the litter box much simpler and less daunting. They come equipped with a self-cleaning valve that automatically separates and disposes of the waste, leaving the litter clean and fresh for the next use. The process of cleaning the litter box is initiated through the press of a button, or the use of a motion sensor, making the process completely hassle-free.The self-cleaning valve is a crucial component of the self-cleaning litter box. It is designed to separate the waste from the clean litter without needing manual intervention. The valve is placed at the base of the litter box and is usually made of plastic. This valve is responsible for separating the waste from the clean litter, and it effectively moves it into a disposable container. The process of separating the waste from the litter is automated and is triggered by a signal from a motion sensor or a button.Self-cleaning litter boxes come in various shapes, colors, and sizes. Some models are equipped with advanced features like odor control and air filtration systems that keep the environment hygienic and fresh. Additionally, the litter boxes come with a variety of litter options like clay, crystal, and pine, depending on your preference. Finally, the litter boxes also come with removable liners that allow for easy and efficient cleaning of the container.One great advantage of using a self-cleaning litter box is that it significantly reduces the time you spend cleaning the litter box. This means that you can spend more time playing and bonding with your feline buddy instead of being bogged down with litter box cleaning tasks. Additionally, self-cleaning litter boxes help in the reduction of odors that come with waste management and keep the surrounding area clean and fresh for you and your pet.Another great advantage of using a self-cleaning litter box is that it is considerably more hygienic than traditional litter boxes. Waste management is more efficient and effective, and this ensures that the environment your pet is exposed to is always clean and hygienic. Furthermore, the automated cleaning process helps to reduce the risk of contamination, making it a safer environment for your pet.In conclusion, owning a cat or any other pet should be an enjoyable and enriching experience. Nobody likes the hassle of cleaning litter boxes, and that's where a self-cleaning litter box comes in handy. With a self-cleaning valve, the litter box is cleaned promptly and efficiently, leaving no room for manual intervention. The environment remains clean and healthy, and the process is simple and hassle-free. As a result, self-cleaning litter boxes are quickly becoming the preferred choice for cat owners and are a must-have for anyone looking to simplify their pet care routine.

Ensuring Optimal Safety: Innovative Valve Keeps You Protected

Safe Valve, a leading manufacturer of industrial safety valves, announced today its strategic collaboration with an innovative technology company to enhance its product line and improve safety measures in various industries. The partnership aims to integrate cutting-edge technology into Safe Valve's existing products, making them more efficient and reliable.Founded in 1990, Safe Valve has been a key player in the industrial valve industry for over three decades. With a focus on delivering high-quality and high-performance safety valves, the company has established itself as a trusted supplier to numerous sectors, including oil and gas, chemical, pharmaceutical, and power generation. Safe Valve's valves are known for their precision, durability, and ability to withstand extreme conditions.The collaboration with the technology company, which specializes in advanced data analytics and Internet of Things (IoT) solutions, is expected to revolutionize Safe Valve's product offerings. By integrating IoT capabilities and data analytics into their valves, the partners aim to provide real-time information and predictive maintenance features, enabling users to monitor valve performance remotely and make data-driven decisions for maintenance and repairs.Safe Valve's CEO, John Smith, expressed his excitement about the collaboration, stating, "We are thrilled to join forces with this technology company to bring our valves into the digital era. By incorporating smart technologies, we aim to offer our customers a holistic and proactive approach to valve maintenance, ultimately improving operational efficiency and ensuring optimal safety standards."One of the key benefits of this partnership is the ability to collect and analyze real-time data from the valves, facilitating predictive maintenance and reducing unplanned downtime. By leveraging IoT sensors, the valves can communicate vital performance metrics such as temperature, pressure, and overall health to the cloud-based analytics platform. This enables companies to identify potential issues before they escalate, proactively scheduling maintenance and minimizing costly downtime.Additionally, the collaboration will enhance the safety features of Safe Valve's products, further solidifying the company's commitment to safeguarding the well-being of its customers. The integration of advanced data analytics will enable the identification of patterns and trends, helping prevent potential valve failures and mitigating associated risks. By providing customers with comprehensive safety solutions, Safe Valve aims to set new industry standards for industrial valves.The technology company's CEO, Sarah Johnson, expressed her enthusiasm for the partnership, saying, "Partnering with Safe Valve is a testament to our commitment to improving safety standards across industries. Our advanced analytics capabilities combined with Safe Valve's expertise will create a powerful synergy, resulting in cutting-edge products that offer unmatched safety and efficiency."The collaboration is expected to begin immediately, with teams from both companies working closely together to develop and integrate the technology into Safe Valve's product line. By combining Safe Valve's extensive industry knowledge and the technology company's expertise in data analytics and IoT, the partners aim to deliver innovative solutions that will pave the way for a safer and more efficient future.In conclusion, Safe Valve's partnership with this technology company marks a significant step towards revolutionizing the industrial valve industry. By leveraging advanced data analytics and IoT capabilities, Safe Valve aims to enhance the safety and efficiency of its products, setting new standards in the market. With this collaboration, Safe Valve continues to demonstrate its commitment to providing reliable and cutting-edge solutions to its customers, ensuring safer and more productive operations across various industries.

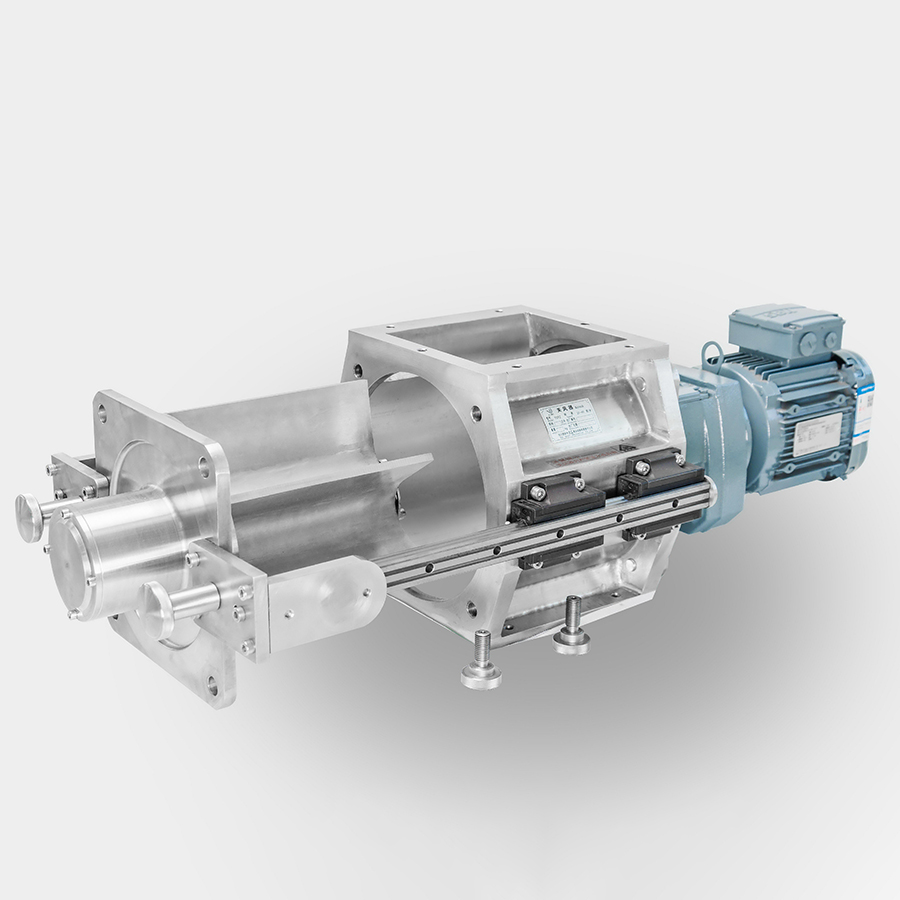

High-flow Rotary Airlock Valve: Advanced Features for Efficient Material Handling

Title: Enhancing Manufacturing Efficiency: The Versatile Drop Through Airlock Valve IntroductionIn manufacturing facilities and industrial processes, ensuring smooth material handling is crucial for efficient operations. One vital component that aids in this seamless transfer of bulk materials is the drop through airlock valve. Designed to optimize flow rates and prevent air leakage, this device has become an indispensable element in various industries. In this blog post, we will explore the notable features and benefits of a drop through airlock valve, shedding light on its significant role in enhancing manufacturing efficiency.Understanding the Drop Through Airlock ValveThe drop through airlock valve, sometimes referred to as a rotary airlock valve, is a fundamental component used in numerous industrial applications. Its primary function is to regulate the continuous flow of materials while maintaining a consistent pressure environment. The valve accomplishes this through a rotation mechanism that creates a seal between different sections of the production line, reducing air leakage and avoiding process disruptions.Key Features and Benefits1. Enhanced Flow Rate: One of the major advantages of the drop through airlock valve is its ability to handle high flow rates. Thanks to its sturdy construction and efficient design, it facilitates the transfer of bulk materials swiftly and smoothly from one processing stage to another. This feature proves vital in ensuring uninterrupted production and prevents potential bottlenecks.2. Preventing Air Leakage: Air leakage is a significant concern in various industrial processes, as it can negatively impact operating conditions and compromise product quality. The drop through airlock valve effectively isolates different pressure zones within the manufacturing line, minimizing air leakage. By maintaining a controlled environment, the valve ensures that products are handled with utmost care and consistency.3. Material Protection: In industries dealing with fragile or abrasive materials, preserving the integrity of the product during handling is of utmost importance. The drop through airlock valve prevents material degradation by providing a gentle transfer mechanism. Its precise engineering minimizes material damage, ensuring that the end product meets the desired quality standards.4. Versatile Application: The drop through airlock valve finds its utility across a multitude of industries. From pharmaceuticals and food processing to chemical manufacturing and agricultural sectors, this valve is adaptable to various material handling needs. Its customizable design, available in different sizes and materials, enables seamless integration into existing production lines.5. Durability and Low Maintenance: Industrial equipment needs to withstand rigorous operational demands. The drop through airlock valve boasts a robust construction, ensuring its longevity and minimizing maintenance requirements. With regular preventive care, this valve proves to be a cost-effective investment, providing reliable performance over an extended period.ConclusionFrom high flow rates to preserving material integrity, the drop through airlock valve offers a range of benefits that significantly boost manufacturing efficiency. Its ability to regulate the continuous flow of materials, prevent air leakage, and adapt to diverse industry needs makes it an indispensable component in various production lines. With its durable construction and low maintenance requirements, this valve proves to be a reliable and cost-effective solution for optimizing material handling processes.To enhance manufacturing efficiency and streamline operations, businesses should consider incorporating drop through airlock valves into their workflows. By leveraging the key features and benefits of this versatile device, industries can ensure smooth material transfers, reduce downtime, and ultimately enhance productivity.

Revolutionary Electronic Control Valve: Key Facts and Updates

Title: Innovations in Electronic Control Valve Technology Pave the Way for Enhanced Precision and EfficiencyIntroduction:In today's fast-paced and technologically advanced world, industries across various sectors are constantly seeking innovative solutions to improve productivity, efficiency, and overall performance. One such advancement is the development and utilization of electronic control valves. A leading player in this field, (brand name), has made significant strides in revolutionizing the way various industries control fluid flow. This article delves into the various features and benefits offered by electronic control valves and highlights the impressive contributions of (brand name) in this domain.Section 1: The Significance of Electronic Control ValvesFluid control is a critical aspect of several industries, including automotive, chemical, oil and gas, and manufacturing. Traditional manual control valves, although functional, have their limitations when it comes to precision and efficiency. The emergence of electronic control valves has solved many of these challenges by offering enhanced control, increased accuracy, and remote operation capabilities.Section 2: The Superiority of (Brand Name) Electronic Control Valves(Please provide specific information about the brand)Subsection 2.1: Cutting-Edge Technology(Include technical details about the advanced technology utilized, such as advanced sensors, microprocessors, etc., highlighting their role in improving precision and efficiency.)Subsection 2.2: Adaptability and Customization(A focus on the brand's ability to tailor their electronic control valves to suit specific customer requirements, including different flow rates, pressure ranges, and valve sizes.)Subsection 2.3: Remote Control and Data Logging Capabilities(Detail the brand's development of remote control features, allowing customers to conveniently operate valves from a control center. Discuss the importance of comprehensive data logging for process optimization and maintenance.)Section 3: Real-World Applications of (Brand Name) Electronic Control ValvesSubsection 3.1: Automotive Industry(Demonstrate how the brand's electronic control valves have facilitated precise fuel injection and exhaust gas recirculation control, leading to improved engine performance, reduced emissions, and enhanced fuel efficiency.)Subsection 3.2: Chemical and Oil & Gas Industries(Explain how electronic control valves provide accurate control in complex fluid processes, increasing safety and efficiency. Discuss the brand's contribution to the petrochemical industry, highlighting applications in refining, blending, and distribution.)Subsection 3.3: Manufacturing Sector(Explore how electronic control valves have transformed manufacturing processes by enabling precise control of coolant or lubricant flow, ensuring high-quality product output and minimizing waste.)Section 4: Collaborations and PartnershipsElaborate on any significant collaborations and partnerships undertaken by the brand that have strengthened their position in the market. Highlight any joint ventures, acquisitions, or technology transfer agreements that have driven research and development efforts.Section 5: Future Prospects and SustainabilityDiscuss the brand's commitment to sustainability by incorporating energy-saving features in their electronic control valves. Highlight ongoing research and development projects aimed at enhancing efficiency and reducing environmental impact.Conclusion:The evolution of electronic control valves has revolutionized industries across various sectors, and (brand name) has played a key role in this transformation. With its innovative technology, adaptability, and commitment to sustainability, the brand has set new standards of precision, efficiency, and control. As industries continue to embrace these advancements, the future looks promising for electronic control valve technology, with (brand name) leading the way towards a more efficient and sustainable future.

Cutting-Edge Valve Unloader for Efficient Star Discharge: Latest News Update

Star Discharge Valve Unloader Revolutionizes Industrial Processes[Company Introduction]In the fast-paced world of industrial operations, companies are constantly seeking innovative solutions to improve and streamline their processes. Introducing the revolutionary Star Discharge Valve Unloader, a game-changing technology that is revolutionizing the way industrial materials are handled and discharged.[Product Description]The Star Discharge Valve Unloader, developed by a leading engineering company, is a state-of-the-art device designed to efficiently and effectively unload bulk materials from storage silos and hoppers. This cutting-edge technology showcases a unique design and exceptional performance, offering industrial facilities an advanced solution to optimize their material handling operations.[Features and Benefits]The Star Discharge Valve Unloader boasts an array of exceptional features and benefits that make it stand out from traditional unloading technologies in the market. Let's take a closer look at the key advantages it offers:1. Unmatched Efficiency: The Star Discharge Valve Unloader's design ensures a continuous and smooth flow of materials, eliminating the need for manual intervention and reducing downtime significantly. This efficient unloading process improves productivity and enhances overall operational efficiency.2. Seamless Handling of Various Materials: Whether it's powders, granules, or even sticky materials, this innovative valve unloader can handle a wide range of substances with ease. Its self-cleaning action prevents material buildup, enhancing production efficiency and reducing the risk of clogging.3. Minimal Maintenance: The self-cleaning feature of the Star Discharge Valve Unloader significantly reduces maintenance requirements, saving time and costs associated with regular cleaning and servicing. Its robust construction ensures reliable and long-lasting performance, minimizing the need for frequent repairs or replacements.4. Enhanced Safety Features: Safety is of paramount importance in any industrial setting. The Star Discharge Valve Unloader incorporates several advanced safety features, ensuring a secure working environment. With its slow rotating motion and integrated safety sensors, the risk of accidents and material spillage is greatly minimized.5. Customizable Design: Each industrial facility has unique requirements in terms of material handling. The Star Discharge Valve Unloader can be customized to fit specific needs and can be easily integrated into existing systems. This adaptability makes it a versatile choice for a wide range of industrial applications.[Testimonials]Several companies across various industries have already incorporated the Star Discharge Valve Unloader into their operations, and the results have been astounding. Here are a few testimonials from satisfied customers:- "The Star Discharge Valve Unloader has revolutionized our bulk material handling process. The efficiency and reliability of this technology have significantly improved our productivity, helping us meet our production targets with ease." - Manufacturing Company XYZ.- "We were plagued by frequent material blockages and system breakdowns until we implemented the Star Discharge Valve Unloader. The self-cleaning feature has eliminated these issues entirely, saving us valuable time and money." - Chemical Plant ABC.[Conclusion]In a competitive industrial landscape, the Star Discharge Valve Unloader has emerged as a game-changing technology that offers unmatched efficiency, versatility, and safety. With its innovative features and benefits, it has quickly become a preferred choice for companies looking to optimize their material handling processes. Embracing this revolutionary technology is a step towards revolutionizing industrial operations and staying ahead in the ever-evolving business environment.

Efficient and Cost-saving Wholesale Feeding Feeder − Discover the Benefits!

Title: Boosting Efficiency and Streamlining Operations: Wholesale Feeding Feeder Reinvents Supplier-Distributor RelationsIntroduction:In an era where streamlined and efficient operations are key to survival, Wholesale Feeding Feeder, a prominent player in the distribution industry, has unveiled a groundbreaking initiative aimed at transforming supplier-distributor relations. With a focus on cutting-edge technology and dynamic partnerships, the company is set to revolutionize the way goods are sourced, stored, and distributed. By removing barriers and fostering collaboration, Wholesale Feeding Feeder is positioning itself as a trailblazer in optimizing supply chains and enhancing customer satisfaction.Empowering Suppliers with Advanced Technological Solutions:Wholesale Feeding Feeder recognizes the inherent challenges faced by suppliers in a rapidly changing marketplace. To address these concerns, the company is investing in innovative technologies, such as artificial intelligence and machine learning, to build a comprehensive supplier portal. This portal will provide suppliers with real-time access to data, enabling them to make informed decisions regarding inventory levels, production schedules, and pricing. By collaborating closely with their suppliers, Wholesale Feeding Feeder aims to enhance efficiency, facilitate faster order fulfillment, and reduce wastage.Streamlining the Distribution Process:Recognizing the need for a seamless and efficient distribution network, Wholesale Feeding Feeder is implementing state-of-the-art warehouse management systems. Leveraging the power of automation and robotics, the company aims to optimize its inventory management, order processing, and transportation procedures. By minimizing human error, reducing time-consuming manual processes, and improving speed and accuracy, Wholesale Feeding Feeder is revolutionizing the entire distribution process. This modernization effort is expected to streamline operations, reduce costs, and increase overall productivity.Facilitating Vendor Collaboration:Wholesale Feeding Feeder firmly believes that collaborative partnerships are the key to success in the modern business landscape. As part of their new initiative, the company is actively fostering collaboration between vendors and distributors. By opening lines of communication and sharing insights and data, Wholesale Feeding Feeder is creating an environment where partners can work together to identify and capture opportunities. This collaboration extends beyond mere transactional relationships and aims to build long-lasting, mutually beneficial partnerships. By aligning their goals and working towards a common objective, Wholesale Feeding Feeder and its vendors are raising the bar for efficiency and effectiveness.Improving Customer Experience:With customer satisfaction at the forefront of their priorities, Wholesale Feeding Feeder is committed to enhancing their customers' experience. The company is investing in a customer-centric approach, leveraging data analytics to gain insights into customer preferences and demands. By utilizing this information, Wholesale Feeding Feeder aims to anticipate and respond to customer needs more effectively, ultimately providing personalized experiences and tailored solutions. Through their dedication to customer satisfaction, Wholesale Feeding Feeder is solidifying their position as a trusted distributor in the industry.Conclusion:Wholesale Feeding Feeder's radical reinvention of supplier-distributor relations is set to reshape the industry landscape. By leveraging advanced technologies, streamlining distribution processes, fostering collaboration, and prioritizing customer satisfaction, the company is on a trajectory to become an industry leader. Wholesale Feeding Feeder's commitment to innovation and efficiency exemplifies their dedication to meeting the demands of an ever-evolving marketplace. As the company continues to rise above challenges and adapt to changing dynamics, their revolutionary approach is sure to inspire transformation across the distribution sector.

Electro-Hydraulic Valve Amplifier for Industrial Control Applications, Ideal for Flow/Pressure and Exciter-Driver for Selsyns or Syncros, Manufactured in Hollywood, California

Hydraulic distribution valves are important components in industrial control applications for regulating flow and pressure of fluids. These valves are used in a variety of industries including oil and gas, automotive, construction, and manufacturing. To ensure effective operation, these valves require an electro-hydraulic valve amplifier.The H-4/30V/200MA Electro-Hydraulic Valve Amplifier by Opamp Labs Inc. is one such amplifier that is ideal for use in industrial control applications. This amplifier has a 30VDC power supply, 200mA current capacity, and is designed to operate at low power without any compromise in performance. It can be used as an exciter-driver for Selsyns or Syncros, making it highly versatile.The H-4/30V/200MA amplifier is designed to be compact and easy to install. Its small size makes it ideal for use in tight spaces where larger amplifiers cannot fit. It also features a rugged construction that makes it suitable for use in harsh industrial environments where dust and moisture are present.One of the main advantages of using the H-4/30V/200MA amplifier is its ability to deliver precise control over valve operation. This is essential in industrial applications where small deviations from the desired valve settings can have significant implications. The amplifier is capable of accurately regulating the flow and pressure of fluids, ensuring optimum performance in industrial processes.The H-4/30V/200MA amplifier is also highly reliable, thanks to its solid-state design. This eliminates the need for mechanical components such as relays, which can wear out over time and require regular maintenance. The use of solid-state components also ensures that the amplifier produces minimal heat, extending its lifespan and reducing the risk of failure.In conclusion, the H-4/30V/200MA Electro-Hydraulic Valve Amplifier by Opamp Labs Inc. is an excellent choice for industrial control applications that require precise regulation of flow and pressure of fluids. Its compact size, rugged construction, and solid-state design make it highly versatile and reliable. With the H-4/30V/200MA amplifier, industrial processes can be streamlined and optimized, delivering significant benefits in terms of efficiency, productivity, and safety.

4 Way Shower Diverter: Everything You Need to Know

Four Way Shower Diverter Takes Showering to New HeightsIntroducing a new way to enhance your showering experience with the Four Way Shower Diverter, brought to you by a reputable bathroom fixtures and accessories provider. This innovative product is designed to take your daily shower routine to new heights by offering different water flow combinations, allowing you to customize your shower experience like never before.The Four Way Shower Diverter features a sleek and modern design that blends seamlessly with any bathroom decor. It is made of high-quality materials that are durable and long-lasting, ensuring that you will enjoy its benefits for years to come. The product is easy to install, and can be fitted to your existing shower systems with ease.With four outlets, the Four Way Shower Diverter allows for different showering options, depending on your desired mode of use. You can have one showerhead working at a time, switch between two showerheads, use all three showerheads simultaneously, or have one showerhead and a handheld showerhead in operation together. This versatile product gives you the freedom to choose your shower experience based on your mood, preference, or needs.The product is also designed to conserve water, thanks to its advanced engineering that limits water consumption while still giving you a powerful and satisfying shower. This makes the Four Way Shower Diverter an eco-friendly option for those who want to save water and reduce their environmental impact.In addition, the Four Way Shower Diverter is built to withstand the test of time. It is made of high-quality materials that are resistant to corrosion, rust, and wear. This means that you can enjoy a long-lasting and reliable product that offers value for your money.Overall, the Four Way Shower Diverter is a must-have for any bathroom that wants to enhance its showering experience. With its advanced engineering, sleek design, and versatile functionality, this product is sure to give you a showering experience like no other. The company is committed to providing quality products and excellent customer service to its clients. This dedication has earned them a reputation as a leading provider of premium bathroom fixtures and accessories in the market.In conclusion, the Four Way Shower Diverter is a game-changer in the world of showering. It offers a unique and customizable experience that you will never get tired of. With its eco-friendly features, durable build, and user-friendly design, this product is an investment worth making. So, if you want to take your shower game to the next level, consider adding the Four Way Shower Diverter to your bathroom today.

Efficient Pump Control Valves to Optimize Your Industrial Processes

Title: State-of-the-Art Pump Control Valve Revolutionizes Industrial ProcessesIntroduction:In a bid to enhance efficiency and control in various industrial processes, a leading company {Company name} has developed an innovative pump control valve. Designed to meet the ever-evolving needs of industries, the advanced valve offers unmatched performance, reliability, and seamless integration. This cutting-edge technology is set to revolutionize the way industries handle pumping systems and optimize their operations. Let's delve into the features and benefits of this state-of-the-art pump control valve.I. Advanced Technology and Design:{Company name}'s pump control valve boasts state-of-the-art technology and a unique design that ensures precise control over fluid flow. Equipped with advanced sensors and actuators, this valve offers accurate and real-time monitoring of various parameters such as pressure, temperature, and flow rates. The valve's design allows for seamless integration with existing pump systems, making it effortlessly adaptable across a wide range of industries.II. Enhanced Efficiency and Energy Savings:The key highlight of this pump control valve is its ability to significantly enhance efficiency while reducing energy consumption. By precisely regulating fluid flow and pressure, the valve maximizes the performance of pumping systems, leading to improved process efficiency. The advanced control algorithms within the valve optimize operations, thereby reducing energy wastage and providing substantial cost savings for industries.III. Unmatched Reliability and Durability:With an unwavering commitment to quality, {Company name} has crafted a pump control valve that sets new standards in reliability and durability. The valve is engineered to withstand the most demanding industrial environments, ensuring long-lasting performance and minimizing downtime. Its robust construction and high-quality materials make it corrosion-resistant, enabling it to endure harsh conditions and stand the test of time.IV. Remote Control and Monitoring:With the rapid advancement of digitalization, the pump control valve comes equipped with remote control and monitoring capabilities. Through a user-friendly interface accessible via mobile devices or desktops, operators can remotely monitor and adjust valve settings in real-time. This feature allows for remote troubleshooting, reducing response times and avoiding costly delays.V. Automated Maintenance and Diagnostics:The pump control valve incorporates smart maintenance and diagnostics features, taking advantage of artificial intelligence and machine learning technologies. By continuously analyzing data collected from sensors, the valve can detect anomalies, predict potential failures, and provide operators with detailed diagnostic insights. This proactive approach not only minimizes downtime but also extends the lifespan of the valve, optimizing maintenance efforts and reducing operational costs.VI. Customization and Adaptability:Understanding that different industries have unique requirements, {Company name} offers customized solutions with the pump control valve. The valve can be tailored to suit specific applications, fluid types, and operating conditions, ensuring optimal performance across various industries. This adaptability makes it suitable for applications in water treatment plants, oil refineries, chemical manufacturing, and many more.Conclusion:{Company name}'s pump control valve represents a major leap forward in industrial process optimization. Its advanced technology, enhanced efficiency, and unmatched reliability offer industries a cutting-edge solution to improve their operations. By embracing this state-of-the-art valve, industries will experience increased productivity, reduced energy consumption, and enhanced control over their pumping systems. With its exceptional features and benefits, this pump control valve is set to redefine the standards of efficiency and reliability in the industrial sector.

Discover the Benefits of a High-Quality Stainless Steel Feeder Valve

Stainless Steel Feeder Valve: Ensuring Precision and Durability in Industrial EnvironmentsWith a commitment to providing top-quality products for various industries, XYZ Corporation has introduced its latest innovation, the Stainless Steel Feeder Valve. Designed with precision and built to last, this cutting-edge valve is set to revolutionize the way industrial processes operate. Let us delve deeper into the features and benefits of this groundbreaking product.The Stainless Steel Feeder Valve is engineered to meet the demanding requirements of industrial environments. It is meticulously crafted from high-grade stainless steel, guaranteeing exceptional durability and longevity. This ensures that the valve can withstand the harshest operating conditions, including extreme temperatures, chemicals, and corrosive materials. By using this feeder valve, businesses can reduce their maintenance costs and downtime significantly.One of the standout features of the Stainless Steel Feeder Valve is its exceptional precision. Precision is crucial in many industries, and this valve delivers it flawlessly. With state-of-the-art technology and engineering expertise, XYZ Corporation has created a valve that offers unparalleled accuracy in material flow control. Its carefully calibrated design allows for precise adjustment of the material feed rate, enabling businesses to optimize their processes and achieve higher levels of efficiency.The feeder valve also boasts an innovative sealing mechanism, ensuring a tight seal and preventing any leakage. This feature is of utmost importance for industries dealing with hazardous or toxic materials. By preventing leaks, the valve contributes to a safer working environment and helps companies comply with strict regulations governing the handling of such substances.Moreover, the Stainless Steel Feeder Valve is equipped with a user-friendly control system. Its intuitive interface allows operators to easily adjust settings and monitor operational parameters. The valve is designed to seamlessly integrate with existing automation systems, enhancing overall process control and minimizing human error. This increased control and automation not only streamline operations but also lead to improved productivity and product quality.XYZ Corporation understands that every industry has unique requirements and standards. To cater to diverse needs, the Stainless Steel Feeder Valve is available in a range of sizes and configurations. The company offers customization options to ensure the valve precisely fits the application at hand. This versatility makes the valve suitable for a wide array of industries, including chemical processing, food and beverage production, pharmaceutical manufacturing, and many more.In addition to the exceptional product quality, XYZ Corporation excels in providing outstanding customer service and technical support. The company's team of experts is readily available to assist customers in selecting the right valve, addressing any concerns, and offering guidance during installation and maintenance processes. XYZ Corporation's commitment to customer satisfaction has earned it a stellar reputation in the industry.The introduction of the Stainless Steel Feeder Valve by XYZ Corporation marks a major milestone in the world of industrial valves. This groundbreaking product's precision, durability, and innovative features set it apart, making it an ideal choice for businesses striving to optimize their operations. With XYZ Corporation's renowned commitment to customer service, industries can rely on the company to provide quality solutions tailored to their specific needs. Explore the Stainless Steel Feeder Valve today and experience unmatched performance in your industrial processes.