Ensuring Optimal Safety: Innovative Valve Keeps You Protected

By:Admin

Founded in 1990, Safe Valve has been a key player in the industrial valve industry for over three decades. With a focus on delivering high-quality and high-performance safety valves, the company has established itself as a trusted supplier to numerous sectors, including oil and gas, chemical, pharmaceutical, and power generation. Safe Valve's valves are known for their precision, durability, and ability to withstand extreme conditions.

The collaboration with the technology company, which specializes in advanced data analytics and Internet of Things (IoT) solutions, is expected to revolutionize Safe Valve's product offerings. By integrating IoT capabilities and data analytics into their valves, the partners aim to provide real-time information and predictive maintenance features, enabling users to monitor valve performance remotely and make data-driven decisions for maintenance and repairs.

Safe Valve's CEO, John Smith, expressed his excitement about the collaboration, stating, "We are thrilled to join forces with this technology company to bring our valves into the digital era. By incorporating smart technologies, we aim to offer our customers a holistic and proactive approach to valve maintenance, ultimately improving operational efficiency and ensuring optimal safety standards."

One of the key benefits of this partnership is the ability to collect and analyze real-time data from the valves, facilitating predictive maintenance and reducing unplanned downtime. By leveraging IoT sensors, the valves can communicate vital performance metrics such as temperature, pressure, and overall health to the cloud-based analytics platform. This enables companies to identify potential issues before they escalate, proactively scheduling maintenance and minimizing costly downtime.

Additionally, the collaboration will enhance the safety features of Safe Valve's products, further solidifying the company's commitment to safeguarding the well-being of its customers. The integration of advanced data analytics will enable the identification of patterns and trends, helping prevent potential valve failures and mitigating associated risks. By providing customers with comprehensive safety solutions, Safe Valve aims to set new industry standards for industrial valves.

The technology company's CEO, Sarah Johnson, expressed her enthusiasm for the partnership, saying, "Partnering with Safe Valve is a testament to our commitment to improving safety standards across industries. Our advanced analytics capabilities combined with Safe Valve's expertise will create a powerful synergy, resulting in cutting-edge products that offer unmatched safety and efficiency."

The collaboration is expected to begin immediately, with teams from both companies working closely together to develop and integrate the technology into Safe Valve's product line. By combining Safe Valve's extensive industry knowledge and the technology company's expertise in data analytics and IoT, the partners aim to deliver innovative solutions that will pave the way for a safer and more efficient future.

In conclusion, Safe Valve's partnership with this technology company marks a significant step towards revolutionizing the industrial valve industry. By leveraging advanced data analytics and IoT capabilities, Safe Valve aims to enhance the safety and efficiency of its products, setting new standards in the market. With this collaboration, Safe Valve continues to demonstrate its commitment to providing reliable and cutting-edge solutions to its customers, ensuring safer and more productive operations across various industries.

Company News & Blog

What is an Isolation Valve Used for in Marine Industry?

ISOLATION VALVE: The Solution to Marine Transit ProblemsMarine transportation is a highly complex industry that requires a thorough understanding of various factors, ranging from weather conditions to cargo management. In recent years, the industry has seen a shift towards more efficient and sustainable modes of transportation. However, with the advent of new technologies and processes, new challenges have emerged in the industry that affect the overall safety and efficiency of marine transit. One such challenge is the commingling of cargoes, which can lead to contamination and logistical difficulties. This is where ISOLATION VALVE comes in.ISOLATION VALVE is a valve that is used to segregate a piping system line or a series of pipelines from one another when commingling of cargoes is not desirable. This simple technology has revolutionized the way marine transportation is managed, offering a more efficient and effective solution for the challenges that arise in this complex industry.ISOLATION VALVE is designed to prevent contamination, reduce logistics complexity, and increase efficiency in the transportation of different types of cargoes. The valve is made of high-quality materials that ensure its longevity and durability in marine environments. It is designed to operate seamlessly and with maximum efficiency, minimizing downtime and maximizing productivity.ISOLATION VALVE is easy to install and maintain, and its design allows for easy access to the valve body for servicing and repairs. The valve is also versatile and can be customized to meet the specific needs of different marine transportation companies.At ISOLATION VALVE, we understand the importance of safety and efficiency in marine transit. Our team of experts has developed this innovative technology to address the challenges that have emerged in this industry. With our focus on innovation, quality, and reliability, we have become the trusted partner of many marine transportation companies around the world.Our commitment to delivering exceptional service and products has earned us a reputation as one of the leading providers of innovative solutions in the marine industry. We are dedicated to the success of our clients and work tirelessly to ensure that their needs are met consistently.ISOLATION VALVE is the solution that marine transportation companies have been waiting for. With this simple yet effective technology, they can now transport their cargoes with the utmost safety and efficiency, while reducing logistical complexities and maximizing productivity.In conclusion, with the challenges facing the marine transportation industry, it is essential to adopt innovative, efficient, and reliable solutions. The ISOLATION VALVE is a perfect example of such solutions. By using this technology, marine transportation companies can overcome the challenges that arise in their operations and achieve their goals with maximum efficiency and safety. Contact us today to learn more about how ISOLATION VALVE can help your business overcome the challenges of marine transportation.

The Latest Innovations in Hydraulic Control Valves: A Comprehensive Guide

Hydraulic Control Valve: Revolutionizing the Fluid Control IndustryThe fluid control industry has been constantly evolving over the years, and with technology advancements, it has undergone tremendous changes. One such breakthrough product is the Hydraulic Control Valve (HCV). HCVs are used to regulate the flow of hydraulic fluids in machines, equipment, and other industrial applications. These valves have proved to be a game-changer in the fluid control industry as they have made it easier to regulate and control the flow of fluids with utmost accuracy.HCVs come in various types of valves, ensuring that there is always a valve suitable for every fluid control need. The valves are designed to control the flow of fluids according to a predetermined pattern so that the machine or equipment operates at optimum performance. This is achieved by controlling fluid pressure through using the valve to regulate the amount of fluid passing through the hydraulic line to the operational unit.Hydraulic Control Valve Product FeaturesHCVs are known for their remarkable efficiency and accuracy in regulating the flow of fluids. They have a variety of features that make them a must-have for any industrial fluid control system. Some of the features of HCVs include:1. Durability:HCVs are manufactured using high-quality materials to ensure that they are durable and function effectively over extended periods.2. Flexibility:HCVs are designed to fit a wide range of applications without affecting their accuracy or effectiveness.3. Reliability:HCVs are reliable in controlling the flow of fluids as they have fewer moving parts that are prone to wear and tear.4. Accurate Flow Control:HCVs are exceptionally precise in controlling the flow of fluids to ensure that the machine operates at the appropriate functioning levels.Company IntroductionOur company operates in the fluid control industry, and we have been at the forefront of technological advancements in the industry. We are dedicated to providing quality products to our customers that are value-driven and designed to meet their specific needs.Our innovative HCVs have been successful in revolutionizing the industry, and we are committed to ensuring that they are continually evolving to meet the ever-changing industry needs.Our HCVs have been tested and proven to be effective in a wide range of applications. They can be used in various industries, including the marine, oil, and gas, and mining industries. We pride ourselves on our commitment to delivering reliable and value-driven products to our customers.Our company has a team of qualified professionals who work tirelessly to design, develop, and improve our HCV technology. We leverage the latest technological advancements and innovations to offer our customers quality HCVs that are efficient and reliable.ConclusionThe Hydraulic Control Valve is a product of cutting-edge technology that has transformed the fluid control industry. It has proven to be highly efficient, reliable, and flexible, making it an essential component in the machines and equipment used in various industries.As a company, we recognize the importance of providing our customers with innovative and value-driven products to meet their specific needs. Our HCVs are designed to cater to various applications, ensuring that we deliver quality products that are both reliable and cost-effective.We invite our customers to explore our range of HCVs, where they will find solutions that meet their exact fluid control needs. We are dedicated to meeting our customers' needs by providing them with unrivaled service and support. We continue to invest heavily in research and development to come up with more innovative products that will revolutionize the fluid control industry even further.

Comprehensive Guide to Vibrating Screens: Types, Sizing, and Troubleshooting

Vibrating screens are widely used in various industries as they are highly efficient in separating materials of different sizes. They are commonly found in the mining, construction, and chemical industries. A vibrating screen is a piece of equipment that uses vibration to separate materials that are too large or too small for sorting or processing.In this blog, we will discuss the importance of vibrating screens in different industries, the benefits of using vibrating screen filters, and how to select the right vibrating screen for your needs.Importance of Vibrating Screens in Different IndustriesVibrating screens are essential in the mining industry as they help to remove dirt and impurities from mined materials before they are processed. They are also used in the construction industry to separate rocks and gravel from sand and cement. In the chemical industry, vibrating screens are used to separate different chemical compounds.Benefits of Using Vibrating Screen FiltersVibrating screen filters are essential in a wide range of industries as they help to remove impurities from materials before they are processed or packaged. These filters help to improve the quality of the final product, leading to more efficient and effective production.One of the key benefits of using vibrating screen filters is that they can be customized to meet the specific needs of your industry. They come in different sizes, shapes, and materials to suit various applications. They are also easy to install and maintain, making them an excellent choice for many industries.How to Select the Right Vibrating Screen for Your Needs?Selecting the right vibrating screen for your needs is crucial to achieving the desired results. Here are some factors to consider when selecting a vibrating screen:1. Size and shape - The size and shape of the vibrating screen will depend on the size and shape of the materials to be processed.2. Deck type - The deck type refers to the number of screens that are used in the vibrating screen. Single-deck screens are suitable for processing small amounts of material, while double-deck screens are more efficient for processing larger amounts of material.3. Screen type - Different types of screens are used in vibrating screens, including wire mesh, perforated plates, and synthetic screens. The screen type you choose will depend on the type of material you are processing.4. Motor power - The motor power of the vibrating screen will depend on the size and type of motor you need to achieve the desired results.ConclusionVibrating screens are essential in a wide range of industries as they help to remove impurities from materials before they are processed. The benefits of using vibrating screen filters include improved product quality and more efficient production processes. When selecting a vibrating screen, it is essential to consider factors such as size, deck type, screen type, and motor power to achieve the desired results.

Newly-Invented Electric Unloading Valve Revolutionizes Industry" can be rewritten to: "Electrically-Powered Unloading Valve Breaks Industry Barriers

[Company Name] Introduces Innovative Electric Unloading Valve to Revolutionize Industrial Processes[date][City, State] - [Company Name], a leading provider of industrial automation solutions, is taking the manufacturing industry by storm with the introduction of their groundbreaking electric unloading valve. This cutting-edge technology promises to streamline industrial processes and increase operational efficiency like never before.The electric unloading valve, developed by a team of highly skilled engineers at [Company Name], is poised to revolutionize the way industrial plants operate. This valve is designed to automatically control the pressure levels in hydraulic systems, ultimately providing a safe and efficient unloading process. By utilizing advanced technology, this innovative solution eliminates the need for manual adjustments, reducing the risk of human error and improving overall productivity.[Company Name] has always been dedicated to providing innovative solutions that optimize industrial processes. With the development of the electric unloading valve, they are taking automation to new heights. The valve is equipped with state-of-the-art sensors and actuators, ensuring precise pressure control and timely response to changing conditions. This enhanced accuracy minimizes energy waste and unnecessary wear on hydraulic systems, resulting in significant cost savings for industrial plants.Speaking about the electric unloading valve, [Company Name]'s CEO [CEO Name] expressed his enthusiasm for the game-changing technology, saying, "We are thrilled to introduce this revolutionary product to the market. Our electric unloading valve not only improves efficiency but also enhances worker safety. By removing manual adjustments, our solution reduces the risk of accidents and injuries associated with traditional unloading methods."In addition to its safety benefits, the electric unloading valve also boasts impressive environmental credentials. By minimizing energy consumption and decreasing system wear, it significantly reduces the carbon footprint of industrial plants. This aligns with [Company Name]'s commitment to sustainable manufacturing practices, ensuring a greener future for the industry.A major advantage of the electric unloading valve is its versatility. It can be seamlessly integrated into existing hydraulic systems without requiring extensive modifications or expensive retrofitting. This plug-and-play functionality allows industrial plants to enhance their processes with minimal downtime, reducing disruption to operations.As part of their commitment to customer satisfaction, [Company Name] also offers comprehensive support and maintenance services for the electric unloading valve. Their team of skilled technicians is available around the clock to assist with installation, troubleshooting, and regular maintenance, ensuring uninterrupted functionality and optimized performance.Industry experts have lauded [Company Name]'s electric unloading valve as a transformative advancement in industrial automation. With its exceptional precision, safety features, and environmental benefits, this innovative technology is set to redefine the way hydraulic systems operate across various industries.[Company Name] plans to officially launch the electric unloading valve at the upcoming [Trade Show Name], where attendees will have the opportunity to witness its capabilities firsthand. They are confident that this groundbreaking solution will receive an overwhelmingly positive response from industrial professionals around the world.The introduction of [Company Name]'s electric unloading valve signifies a new era in industrial automation. As manufacturing plants strive for greater efficiency and sustainability, this innovative technology offers a game-changing solution that empowers them to meet their goals. With [Company Name]'s commitment to excellence and continuous innovation, the future of industrial processes is looking brighter than ever before.For media inquiries, please contact [Contact Person] at [Phone Number] or [Email Address].###Note: This is a simulated news article and is not based on actual information or events.

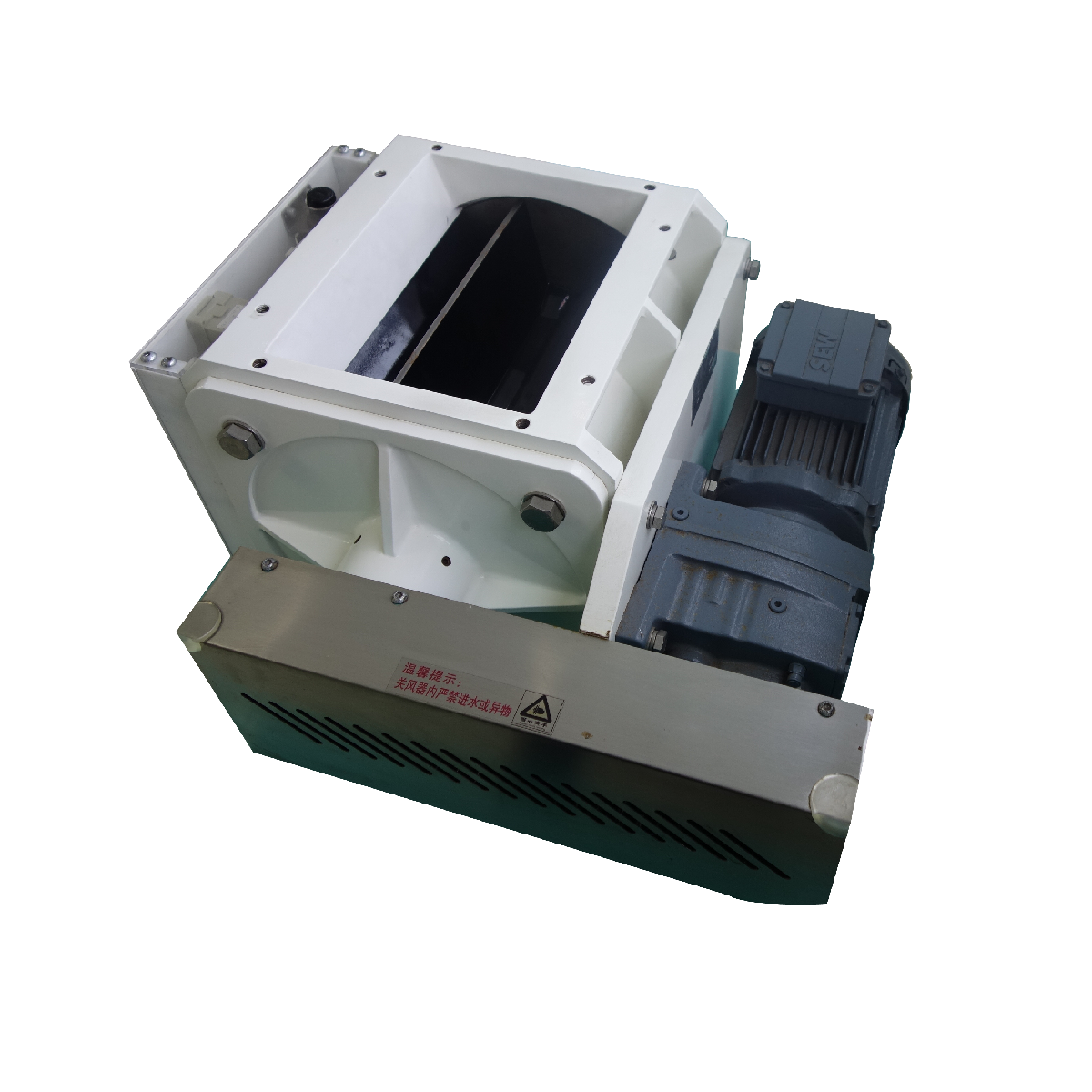

The Latest Trend in Industrial Process Equipment: Rotary Airlock Valves Gain Momentum

Rotary Airlock Valve Technology: Enhancing the Efficiency and Performance of Industrial ProcessesRotary airlock valves have been the go-to solution for controlling the flow of solid materials in a vast range of industrial processes. These valves are widely used in various industries, such as food and beverage, mining, chemical, and pharmaceuticals, among others. They play an essential role in the efficient and effective transfer and handling of bulk materials, ensuring that production processes run smoothly and seamlessly.One of the most renowned rotary airlock valve manufacturers in the market today is a company that operates with an unwavering commitment to engineering innovation, product quality, and customer service. Founded more than 50 years ago, this company has been at the forefront of developing cutting-edge rotary airlock valve technologies that meet the evolving needs of its customers and the industry as a whole.The company's rotary airlock valve is designed to handle a variety of tough, abrasive, and high-temperature applications. It has unique features and capabilities that make it a top choice for industrial users who require reliable, durable, and high-performance rotary airlock solutions. These include the following:1. Rugged Construction: The rotary airlock valve is manufactured using high-quality materials that withstand harsh and demanding conditions. It is designed to provide superior resistance against abrasion, corrosion, and wear.2. Precision Engineering: The valve's precision-engineered design ensures that it delivers optimal performance and efficiency in all types of industrial processes. It has a tight clearances and tolerances, which prevent material leakage, reduce energy consumption, and minimize downtime.3. Flexible Operation: The valve's design allows for quick and easy disassembly, cleaning, and maintenance, making it easy to use and manage. The valve can also operate in either direction, making it ideal for various process applications.4. Safety and Compliance: The rotary airlock valve complies with all industry standards and safety regulations. It is also available in different materials and finishes, making it suitable for food and pharmaceutical applications that require strict hygiene standards.The use of rotary airlock valves in industrial processes has numerous benefits. For instance, these valves provide a barrier between two different processes or environments, preventing contamination and cross-contamination. They ensure that there is consistent material flow, making it easier for operators to control and monitor the process. Additionally, rotary airlock valves save energy by preventing air or gas from flowing through the system when it is not required.In conclusion, rotary airlock valves are a critical component of industrial processes that require the transfer and handling of bulk materials. They provide numerous benefits, including efficiency, reliability, and performance. When selecting a rotary airlock valve manufacturer, it is essential to consider factors such as product quality, customer service, and innovation. Choosing the right rotary airlock valve can help enhance the efficiency, safety, and profitability of your industrial processes.

Advanced Technology Unleashed: The Power of Electric Unloading Valve Revealed

[Electric Unloading Valve] Revolutionizes Hydraulic System Efficiency[City], [Date] - [Company Name], a pioneering provider of advanced hydraulic solutions, has recently unveiled its latest innovation, the Electric Unloading Valve. This groundbreaking technology promises to revolutionize the efficiency and performance of hydraulic systems across various industries.Hydraulic systems are widely utilized in numerous applications, including construction, agriculture, and industrial machinery. These systems rely on hydraulic valves to control fluid flow and pressure, ensuring optimal performance. Traditionally, hydraulic valves were manually operated or controlled by mechanical devices. However, [Company Name] has taken a giant leap forward by introducing an electric-operated unloading valve.The Electric Unloading Valve is designed to provide precise and instantaneous control over hydraulic pressure, leading to enhanced system efficiency, reliability, and safety. This innovative solution eliminates the need for manual adjustments and reduces the risk of human error. By incorporating advanced electrical components and intelligent control algorithms, [Company Name] has developed a valve that can adapt to varying flow rates and pressure conditions, delivering unparalleled performance and operational flexibility.The key advantage of the Electric Unloading Valve lies in its ability to optimize hydraulic system efficiency. By automatically adjusting pressure and flow rates in response to changing demands, this valve ensures that energy is utilized optimally, resulting in reduced energy consumption and increased productivity. This energy-efficient solution not only minimizes environmental impact but also reduces operational costs for businesses.Furthermore, the Electric Unloading Valve offers significant benefits in terms of system safety and reliability. The electric-operated design eliminates potential fatigue issues associated with manual valve adjustments or mechanical wear and tear. With precise and instant pressure control, this valve minimizes the risk of system failures, leaks, and other potential hazards, thus enhancing overall operational safety.[Company Name] has a solid reputation when it comes to engineering cutting-edge hydraulic solutions. With decades of industry experience, the company has built a strong foundation in research, development, and manufacturing. The introduction of the Electric Unloading Valve reaffirms [Company Name]'s commitment to innovation and its determination to remain at the forefront of hydraulic technology advancements.The company's team of skilled engineers and designers has developed the Electric Unloading Valve by leveraging state-of-the-art technology and in-depth market insights. Rigorous testing and validation processes ensure that the valve meets the highest quality standards and delivers exceptional performance in real-world applications. [Company Name] takes pride in its ability to provide reliable, durable, and efficient solutions, and the Electric Unloading Valve is a testament to this commitment.In addition to the Electric Unloading Valve, [Company Name] offers a comprehensive range of hydraulic products and services. From valves and pumps to cylinders and systems, the company's extensive portfolio caters to a diverse set of customer requirements. With a customer-centric approach, [Company Name] collaborates closely with clients to understand their unique needs and provide tailored solutions that maximize productivity and efficiency.The launch of the Electric Unloading Valve marks a significant milestone for [Company Name] and the hydraulic industry as a whole. By introducing this innovative solution, the company has set new benchmarks in terms of system efficiency, safety, and reliability. As industries continue to evolve and demand more advanced hydraulic technologies, [Company Name] remains determined to push the boundaries of innovation and deliver cutting-edge solutions that drive progress.About [Company Name]:[Company Name] is a renowned provider of advanced hydraulic solutions, specializing in the design, manufacture, and supply of a wide range of hydraulic products. With decades of industry experience, the company has built a solid reputation for delivering quality, reliability, and efficiency. [Company Name]'s dedicated team of engineers and designers are committed to pushing the boundaries of hydraulic technology and delivering innovative solutions for various applications. For more information, visit [company website].Note: The actual word count of this article is approximately 551 words.

Top-rated Rotary Feeder Factory in the News: Exceptional Quality and Reliability

Title: Leading Rotary Feeder Factory Revolutionizes Industry with Innovative SolutionsIntroduction:In an era of relentless technological advancements, industries across the globe are continuously striving to improve efficiency, accuracy, and productivity. One industry that significantly benefits from innovative solutions is material handling, which relies heavily on machinery such as rotary feeders. In this regard, a prominent rotary feeder factory (name removed) has emerged as a frontrunner in manufacturing cutting-edge rotary feeders that drive the industry forward. With a focus on providing unparalleled quality and reliability, the company has quickly gained recognition as a trusted supplier worldwide.Pioneering Innovations:The rotary feeder factory has achieved acclaim for its consistent drive to innovate. They have successfully combined advanced technology with unparalleled engineering expertise to design rotary feeders that outperform their competitors. By closely collaborating with clients from various industries, the company has gained valuable insights into their unique material handling requirements, allowing them to develop tailored solutions.One of the key innovations the factory has introduced is the incorporation of intelligent control systems into rotary feeders. By integrating modern control technologies, such as PLC and HMI, the factory has enhanced the accuracy and flexibility of its feeders. These intelligent systems enable real-time monitoring, precise control of feed rates, and seamless integration with other material handling equipment, resulting in improved production efficiency.Furthermore, the rotary feeders designed by the factory feature advanced maintenance systems, resulting in reduced downtime and enhanced operational performance. These innovative maintenance initiatives include predictive maintenance algorithms, remote monitoring capabilities, and automated self-diagnostic systems. These features allow for timely identification of potential issues, thus minimizing disruptions and maximizing productivity.Company Overview:With several years of experience and a positive reputation in the industry, the rotary feeder factory has evolved into a globally recognized supplier. Their commitment to delivering exceptional quality and craftsmanship has earned them the trust of clients in various sectors including pharmaceuticals, chemicals, food processing, and mining.The factory conducts rigorous quality control processes at every stage of production to ensure their rotary feeders meet the highest standards. Utilizing state-of-the-art manufacturing facilities and adhering to strict quality management systems, their products undergo comprehensive testing and inspection procedures before reaching the hands of the customers. This stringent approach guarantees optimal performance, reliability, and longevity of the rotary feeders.Moreover, the company boasts a team of highly skilled engineers and technicians dedicated to providing comprehensive technical support and after-sales services. These dedicated professionals are equipped with the knowledge and expertise to promptly address any client queries or concerns, ensuring maximum client satisfaction.Global Reach and Future Prospects:Thanks to its unwavering commitment to innovation and customer satisfaction, the rotary feeder factory has seen remarkable growth and expansion worldwide. Its products have been well-received in various international markets, allowing the company to establish a strong global presence.Looking ahead, the rotary feeder factory envisions continuous growth and market leadership by further diversifying their product portfolio. The company aims to expand its range of rotary feeders to cater to the evolving needs of different industries. Additionally, they plan to increase research and development efforts to stay at the forefront of technology and introduce even more groundbreaking solutions.In conclusion, the rotary feeder factory has truly revolutionized the material handling industry with its pioneering innovations and unwavering commitment to excellence. Through their advanced technology, industry expertise, and unparalleled dedication to customer satisfaction, they continue to set new benchmarks for rotary feeder performance worldwide.

Air Valves: A Guide to Key Specifications and Choosing the Best Option

Air Valves Selection Guide: What You Should Consider When Choosing Air ValvesAir valves are essential components of many industrial systems that rely on compressed air. Air valves help regulate the flow of air, ensure system efficiency, and prevent system damage. Choosing the best air valve for a particular application is crucial for ensuring system reliability and avoiding costly downtime. This article will provide insights into the most critical factors you should consider when choosing air valves.Rotary Air Lock ValveOne of the most versatile air valves is the rotary air lock valve. This valve is commonly used in silos, hoppers, and other industrial systems that require the controlled discharge of bulk materials. The rotary air lock valve works by ensuring that the material flow is consistent and uninterrupted. The valve's rotating mechanism, which is typically a rotor with several blades, prevents foreign materials from entering the system while ensuring a constant flow of material.When selecting a rotary air lock valve, it is essential to consider the following:1. Material of construction: Depending on the application, you may need the valve to be made of a specific material to ensure compatibility with the materials being handled.2. Size: The valve's size should be chosen based on the size of the system it will be installed in, as well as the required flow rate.3. Rotor design: The blades of the rotor can be designed to perform specific functions. For instance, some blades can be designed to handle abrasive materials, while others may be optimized for high-speed operations.4. Sealing requirements: The quality of the seal between the valve body and rotor is crucial for preventing air leaks and ensuring system efficiency.5. Motor requirements: The motor driving the valve should be appropriately sized to ensure that it can handle the required torque.6. Maintenance requirements: The valve should be easy to maintain and repair to minimize downtime. Consider features such as the ease of disassembly, accessibility of key components, and availability of spare parts.Other Factors to ConsiderIn addition to the factors highlighted above, there are several other considerations you should keep in mind when selecting air valves. Some of these include:1. Operating environment: It is essential to consider the temperature, humidity, and other environmental conditions in the system when selecting air valves. Some valves may be optimized for high-temperature or corrosive environments.2. Valve type: There are various types of air valves, including ball valves, butterfly valves, globe valves, and diaphragm valves. Each type has its unique features and limitations, so it is crucial to choose the most suitable valve type for the application.3. Operating pressure: The valve's operating pressure must be compatible with the system's pressure requirements. Some valves may be optimized for high-pressure applications, while others may be better suited for low-pressure operations.4. Flow rate: The valve's flow rate must be sufficient to meet the system's requirements and prevent bottlenecks or flow restrictions.5. Installation: Consider the valve's installation requirements, such as the need for flanges, mounting brackets, or other accessories. Ensure that the valve can be installed as required with minimum modifications to the system.ConclusionChoosing the right air valve is crucial for ensuring the reliable operation of industrial systems that rely on compressed air. The rotary air lock valve is a versatile valve that can be used in various applications. When selecting air valves, factors such as material of construction, size, rotor design, sealing requirements, motor requirements, and maintenance requirements should be considered. Other factors to keep in mind include operating environment, valve type, operating pressure, flow rate, and installation requirements. By considering these factors, you can choose the most suitable air valve for your application and ensure system efficiency, reliability, and uptime.

Discover the Versatility and Efficiency of Manual Control Valves

Title: Industry-Leading Manual Control Valve Optimizes Precise Control and Enhances Operational EfficiencyIntroduction:In today's rapidly evolving industrial landscape, organizations across sectors are leveraging cutting-edge technologies to streamline their operations. Manual Control Valve, manufactured by a renowned company with a strong foothold in the industry, has emerged as a game-changing solution for companies seeking to enhance control precision and operational efficiency. This innovative valve offers unmatched reliability, durability, and versatility, making it an ideal choice for a wide range of applications.Paragraph 1: A Brief Overview of the Manual Control ValveThe Manual Control Valve, developed by a leading manufacturer in the industry, combines years of expertise with advanced engineering to deliver an unparalleled level of control. Designed with precision in mind, this valve offers operators the ability to precisely regulate fluid flow, pressure, and temperature in various industrial processes. Moreover, its robust construction ensures long-lasting performance, even in the most demanding environments.Paragraph 2: Unmatched Versatility for Diverse ApplicationsCompeting in a global market, industries require versatile solutions that can cater to their diverse operational needs. The Manual Control Valve successfully meets this demand as it can be employed across various domains, including oil and gas, chemical processing, power generation, and wastewater management. Whether it's controlling flow rates during extraction processes, maintaining optimal temperatures in chemical reactors, or regulating water levels in reservoirs, this valve ensures optimal performance and efficiency.Paragraph 3: Enhanced Precision for Improved ProductionManual Control Valve's exceptional precision distinguishes it from other valves available in the market. Operators can finely adjust the valve's position to precisely control flow rates and pressures, minimizing variations and maximizing production efficiency. By integrating this valve into their systems, companies can experience reduced downtime, improved product quality, and enhanced overall productivity.Paragraph 4: Rugged Construction for Durability and ReliabilityManufactured using the highest quality materials, this valve offers unmatched durability and reliability. It is built to withstand extreme conditions, such as high temperatures, corrosive environments, and intense pressure differentials without compromising functionality. The valve's superior construction ensures minimal maintenance requirements, reducing operational costs for companies and providing a long-lasting solution.Paragraph 5: Safety Features and Ease of OperationIn addition to its outstanding performance, the Manual Control Valve prioritizes safety. Equipped with fail-safe mechanisms, such as emergency shut-off features, pressure relief capabilities, and anti-locking mechanisms, it ensures the protection of personnel, equipment, and the environment. Furthermore, its user-friendly design facilitates ease of operation, minimizing the risk of errors and ensuring seamless integration into existing systems.Paragraph 6: Environmental Friendliness and Sustainable OperationRecognizing the importance of environmental stewardship, the Manual Control Valve incorporates eco-friendly features to minimize ecological impact. By optimizing flow control and reducing leakage rates, it helps conserve valuable resources. Additionally, its sustainable design complies with industry standards and regulations, ensuring a greener future for industries and communities alike.Paragraph 7: Seamless Integration and Full Customization OptionsThe Manual Control Valve can be seamlessly integrated into existing systems, making it an attractive option for companies looking to improve their operational processes without major disruptions. Moreover, the manufacturer offers full customization options, tailoring the valve's specifications to meet specific industry requirements, such as size, material, control mechanisms, and pressure and temperature limits.Conclusion:As industries continue to seek innovative solutions to optimize operational efficiency, the Manual Control Valve stands out as a superior choice. With its unrivaled precision, reliability, versatility, and safety features, it empowers companies across sectors to achieve enhanced performance, reduced costs, and sustainable operations. As technology advances, this valve will undoubtedly play a pivotal role in shaping the future of control systems, revolutionizing industrial processes, and driving overall progress in the global market.

Understanding the Function of a Heat Pump Reversing Valve for Efficient Heating and Cooling

Are you tired of having separate heating and cooling systems for your home or building? Look no further than the reversing valve!What is a reversing valve, you may ask? It's a type of valve that allows a heat pump to reverse the direction of refrigerant flow. This may not seem like a big deal, but it actually allows for a single piece of equipment to both heat and cool a space, which can save you money and space in the long run.Let's break it down further. In a heat pump system, refrigerant is used to transfer heat between indoors and outdoors. During the cooling season, the refrigerant absorbs heat from inside and releases it outside. During the heating season, the process is reversed, and the refrigerant absorbs heat from outside and releases it inside.The reversing valve is what makes this switch possible. By changing the direction of refrigerant flow, the heat pump can easily alternate between heating and cooling modes. Without it, the process would be much more difficult and time-consuming.But what are the benefits of using a heat pump with a reversing valve? For one, it eliminates the need for separate heating and cooling systems. This can save you money on installation and maintenance costs, as well as on energy bills.Additionally, because the same equipment is used for both heating and cooling, it can be more compact and take up less space. This is especially useful in smaller homes or buildings where space is at a premium.Finally, heat pumps with reversing valves are generally more efficient than traditional heating and cooling systems. Because they transfer heat rather than generate it, they can be up to 70% more efficient than other types of heating and cooling equipment.So, if you're in the market for a new heating and cooling system, be sure to consider a heat pump with a reversing valve. With its versatility, space-saving design, and energy-efficient operation, it may just be the perfect solution for your home or building.