China's Leading Pneumatic Solenoid Valve Manufacturers, Suppliers, and Factory

Read More

Top 10 Diet Tips for Maintaining a Healthy Weight

Title: Revolutionary Content Star Feeder Revolutionizes the Digital Marketing LandscapeIntroduction:In this digital age where content is king, businesses are constantly on the lookout for innovative tools and strategies to stay ahead of the competition. Enter Content Star Feeder, a pioneering platform that is revolutionizing the way companies approach their digital marketing efforts. By harnessing advanced technologies and sophisticated algorithms, Content Star Feeder enables businesses to effectively disseminate and manage their content across various online channels, boosting engagement, visibility, and ultimately, business growth.I. The Rise of Content Marketing:Over the past decade, content marketing has emerged as a powerful strategy for businesses to connect with their target audience on a deeper level. With the proliferation of social media platforms, blogs, and online communities, companies have recognized the need to create engaging and valuable content to capture the attention of consumers. Content Star Feeder has recognized this trend and developed a platform that streamlines the content marketing process, empowering businesses to deliver their message effectively and efficiently.II. How Content Star Feeder Works:Content Star Feeder utilizes cutting-edge technology to automate and optimize the content marketing process. Through an intuitive and user-friendly interface, businesses can effortlessly create, distribute, and measure the impact of their content across multiple channels. The platform aggregates data from various sources to generate insights and recommend the most effective strategies to engage with target audiences.III. Key Features and Benefits:a) Content Creation and Curation: Content Star Feeder enables businesses to develop and curate high-quality content that resonates with their target audience. With a comprehensive suite of tools, including customizable templates, image editing, and video creation capabilities, companies can easily create visually stunning and compelling content.b) Seamless Distribution: The platform seamlessly integrates with popular social media networks, websites, and email marketing systems. This ensures the widest reach and maximum visibility for each piece of content, driving more traffic and generating leads.c) Analytics and Reporting: Content Star Feeder provides in-depth analytics and reporting functionalities, allowing businesses to track the performance of their content marketing efforts. With detailed insights on engagement, conversions, and audience behavior, companies can refine their strategies and optimize their content for better results.d) Collaboration and Team Management: The platform facilitates collaboration among team members, ensuring seamless coordination and alignment in content creation and distribution. Through a centralized workflow, businesses can streamline their content marketing operations and enhance productivity.IV. Success Stories:Several businesses have already harnessed the power of Content Star Feeder and experienced remarkable outcomes. An e-commerce company, for instance, saw a significant increase in website traffic and sales after incorporating the platform into their marketing strategy. Another example is a healthcare provider who successfully engaged their target audience through compelling content, resulting in improved brand awareness and patient acquisition.V. Future Innovation and Expansion:Content Star Feeder is committed to continuous innovation and development. The platform's team of experts is constantly exploring new technologies, such as artificial intelligence and machine learning, to enhance the capabilities and effectiveness of their solution. Additionally, the company has plans to expand its services globally, catering to businesses of all sizes and industries.Conclusion:Content Star Feeder has emerged as a game-changing solution in the digital marketing landscape, empowering businesses to optimize their content marketing efforts like never before. By providing an all-in-one platform that streamlines content creation, distribution, and analytics, businesses can achieve greater visibility, engagement, and ultimately, success in the highly competitive digital arena. With the promise of continuous innovation and global expansion, Content Star Feeder is set to shape the future of content marketing.

Read More

High Quality Trunnion Mounted Ball Valves with Tight Seal for Upstream and Downstream Flow Blockage - API 6D and Gost Compliant

Introduction:Trunnion mounted ball valves are used in many industries to control the flow of liquids and gases. These valves are designed to block the flow from upstream and downstream with a bubble-tight seal. The trunnion ball valve is designed to API 6D and GOST Standard, ensuring that it meets the highest possible industry standards. In this blog, we will discuss the features and benefits of trunnion mounted ball valves, their applications, and why they are a popular choice for many industries.Features and Benefits:Trunnion mounted ball valves have many features and benefits that make them an attractive choice for many industries. Here are some of the key benefits of trunnion ball valves:1. Bubble-Tight Seal: Trunnion ball valves are designed to provide a bubble-tight seal, ensuring that there is no leakage of liquid or gas. This makes them ideal for applications where safety is a top priority.2. Low Torque: The trunnion ball valve requires low torque to operate, which means that it is easy to open and close. This is a major advantage for large valves that need to be operated manually.3. Full Bore: Trunnion ball valves have a full bore design, which means that the flow rate is not restricted. This allows for a high volume of fluid or gas to flow through the valve.4. High Pressure and Temperature: Trunnion ball valves are designed to operate at high pressures and temperatures, making them suitable for use in challenging environments.Applications:Trunnion ball valves are commonly used in the following industries:1. Oil and Gas: Trunnion ball valves are ideal for use in the oil and gas industry, where they are used to control the flow of fluids and gases in pipelines, tanks, and storage facilities.2. Chemical: Trunnion ball valves are also used in the chemical industry to control the flow of hazardous and corrosive chemicals.3. Water Treatment: Trunnion ball valves are used in water treatment plants to control the flow of water and other liquids.4. Power Generation: Trunnion ball valves are used in power generation plants to control the flow of steam and other gases.Conclusion:The trunnion mounted ball valve is a popular choice for many industries due to its bubble-tight seal, low torque requirements, full-bore design, and ability to operate at high pressures and temperatures. Trunnion ball valves are used in a variety of applications, including oil and gas, chemical, water treatment, and power generation. If you're looking for a reliable and efficient valve for your industry, consider the trunnion mounted ball valve.

Read More

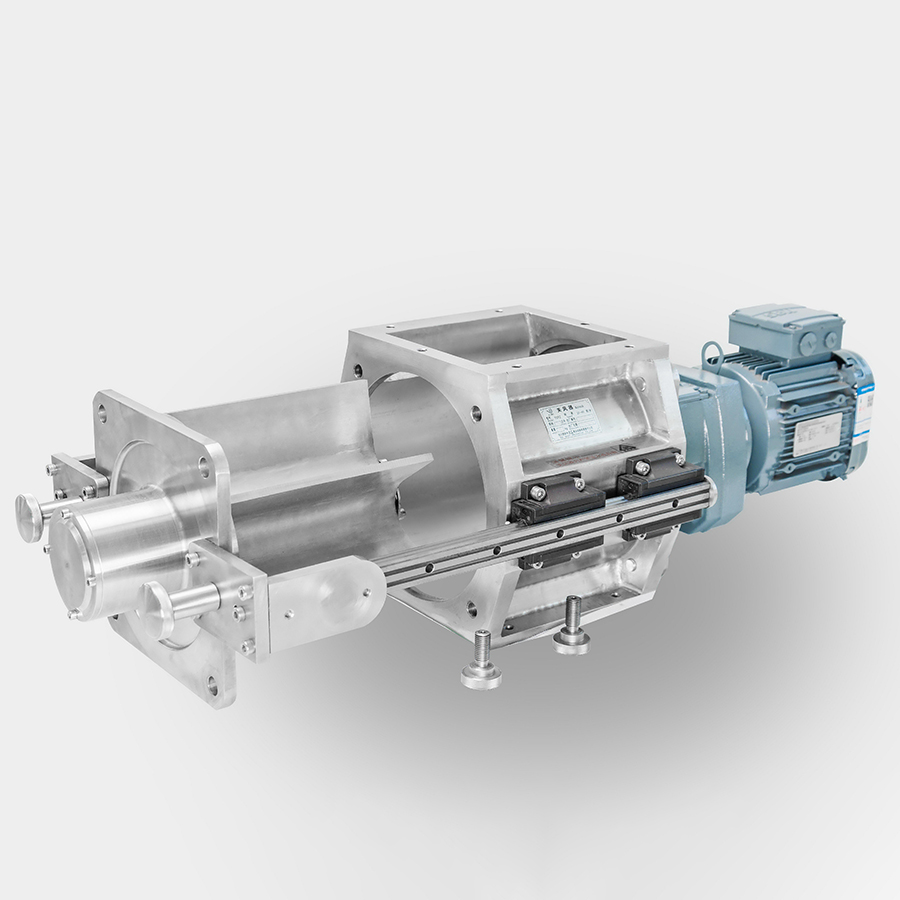

Major News: Unveiling an Innovative Content Drop Method via Rotary Valve

Title: Industry Leading Valve Manufacturer Introduces Revolutionary Content Drop SolutionIntroduction:In the relentless pursuit of innovation and advancement, renowned valve manufacturer X has recently introduced a groundbreaking technology called the Content Drop through Rotary Valve (CDRV). As a leading player in the industry, X continues to excel in providing state-of-the-art solutions to various sectors. With the introduction of CDRV, the company aims to revolutionize the valve manufacturing process, offering enhanced efficiency, precision, and reliability while catering to the diverse needs of their clients.1. Background of Valve Manufacturing Industry:The valve manufacturing industry plays a crucial role in numerous sectors, including oil and gas, chemical processing, power generation, and water treatment. Valves are essential components that control the flow of fluids and gases, ensuring safe and reliable operations. As technology advances, companies are constantly seeking new solutions to address the challenges posed by demanding applications, fluctuating temperatures, and the need for efficiency.2. Introducing Content Drop through Rotary Valve (CDRV):X's CDRV innovation encompasses a revolutionary approach to valve manufacturing. The new technology allows for the seamless introduction of metered content into the valve chamber, enabling precise control while improving efficiency and reducing downtime. Through the Content Drop mechanism, operators can accurately regulate the flow and properties of the content, ensuring optimal performance and reliability.3. Enhanced Efficiency and Precision:CDRV significantly improves the efficiency and precision of the valve manufacturing process, minimizing wastage, and reducing operational costs for clients. With the Content Drop mechanism, the valves can be customized to meet specific requirements, whether it be controlling fluid flow, pressure, or temperature regulation. The advanced design allows for seamless integration into existing systems, requiring minimal modifications and enhancing productivity.4. Reliability and Safety:Maintaining utmost reliability and safety standards is paramount in the valve manufacturing industry. X's CDRV solution ensures the consistent and precise function of valves, reducing the risk of leaks, downtime, and potentially hazardous situations. By incorporating advanced technology and engineering practices, X provides clients with peace of mind, knowing that their operations are secure and optimized.5. Wide-Spectrum Applications:X's CDRV innovation caters to a wide range of applications across various industries. From the rigor of the oil and gas sector, where valves are subjected to extreme temperatures and pressures, to the sensitive requirements of the pharmaceutical and food industries, valving solutions need to meet stringent criteria. The Content Drop through Rotary Valve system caters to this diverse array of applications, offering unparalleled versatility and adaptability.6. Sustainable Manufacturing Practices:X is committed to sustainable manufacturing processes and environmental responsibility. The CDRV technology aligns with the company's core values by minimizing material wastage and optimizing energy consumption. By reducing the need for extensive maintenance and overhauls, X's CDRV solution ensures extended operational life cycles, resulting in reduced waste generation and a greener footprint.Conclusion:X's introduction of Content Drop through Rotary Valve (CDRV) highlights their ongoing commitment to innovation and industry excellence. This game-changing technology allows for enhanced efficiency, precision, and safety in valve manufacturing, catering to a broad range of applications. With its versatility, reliability, and sustainability focus, X reaffirms its market leadership and continues to drive the valve manufacturing industry towards a more advanced and efficient future.

Read More

ANSI-standard Inverted Pressure Balance Lubricated Plug Valves available

Inverted Pressure Balance Lubricated Plug Valve According to ANSI API 599 and API 6DValves are integral components in pipelines used for controlling the flow of liquids and gases. There are different types of valves, and each type has unique features that make it suitable for specific applications. One type of valve that has gained popularity in recent years is the Inverted Pressure Balance Lubricated Plug Valve according to ANSI.Inverted Pressure Balance Lubricated Plug Valve or IPB valve is a type of valve that is commonly used in hydrocarbon, petrochemical, and chemical applications. It is designed to provide effective sealing and reliable operations even at high pressures and temperatures. The valve has a plug-like structure with a hole in its center that allows the flow to pass through.The IPB valve is designed to operate with a minimum amount of torque required to open and close the valve. This is made possible through the use of an inverted pressure balance design that allows the pressure inside the valve to balance with the pressure outside the valve. As a result, the valve can be easily and smoothly operated, reducing the risk of damage and wear and tear.Another key feature of the IPB valve is its lubrication system. The valve is designed to be equipped with a lubrication system that allows for easy and regular maintenance. The lubrication system helps to ensure that the valve’s plug and stem are always well-lubricated, reducing the risk of corrosion and enhancing the valve’s lifespan.The ANSI standards for Inverted Lubricated Plug Valve, namely API 599 and API 6D, are the benchmarks for the manufacturing and quality control of such valves. These standards specify the design, material, and testing requirements for IPB valves. Manufacturers who abide by these standards are more likely to produce high-quality valves that operate effectively and efficiently.In conclusion, the Inverted Pressure Balance Lubricated Plug Valve according to ANSI is an ideal option for those looking for a reliable and efficient valve for their applications. With its unique design and lubrication system, the IPB valve can operate smoothly and reliably, even in high temperatures and pressures. It is essential to choose a manufacturer who strictly adheres to the ANSI standards to ensure that you get a high-quality valve that meets your requirements.

Read More

Types of Rotary Valve: Applications, Components and Limitations of Rotary Airlock Valve - Engineering Learn

Read More

WYK Bulk Material Diverter Valve and ZV Rotary Valve Unveiled at Powtech 2019

and rotary valve Bulk material handling is a crucial process in any industrial setting. It involves moving large quantities of materials from one location to another, while ensuring that no loss or contamination occurs during the transfer. Bulk material handling systems must be efficient, reliable, and versatile to meet the needs of a wide range of industries worldwide.At Powtech 2019, Coperion and Coperion K-Tron introduced two new products that are aimed at improving the performance of bulk material handling systems. These products are the WYK Bulk Material Diverter Valve and the ZV Rotary Valve.The WYK Bulk Material Diverter Valve is a high-performance valve that is designed to handle powders, pellets, and granules with ease. It features a rugged design that ensures reliable performance even under the toughest conditions. The WYK Bulk Material Diverter Valve can be used for diverting, converging, and merging bulk materials, making it a versatile tool for any bulk material handling system.One of the most notable features of the WYK Bulk Material Diverter Valve is its ability to handle abrasive materials without suffering from wear and tear. This is made possible by the valve's special design, which features a wear-resistant coating on the valve body's interior surfaces.Another feature that makes the WYK Bulk Material Diverter Valve stand out is its ability to maintain a high level of accuracy during valve switching. This is achieved by the use of a special patent-pending technology that ensures that the valve changes from one position to another without any loss of material.The ZV Rotary Valve, on the other hand, is a highly efficient valve that is designed for feeding and metering bulk materials. It features a sleek design that allows it to fit into tight spaces, making it ideal for use in applications where space is limited.The ZV Rotary Valve is available in a variety of sizes, ranging from 150 mm to 350 mm, making it suitable for a wide range of applications. The valve is also compatible with a broad range of materials, including powders, pellets, and granules.One of the standout features of the ZV Rotary Valve is its ability to handle high throughputs without compromising accuracy. This is made possible by the use of a patent-pending technology that ensures that the valve maintains a constant feed rate, regardless of the material being handled.In conclusion, the introduction of the WYK Bulk Material Diverter Valve and the ZV Rotary Valve at Powtech 2019 is a clear indication of Coperion and Coperion K-Tron's commitment to improving the performance of bulk material handling systems. These products are versatile, efficient, and reliable, making them ideal for a wide range of applications. With the WYK Bulk Material Diverter Valve and the ZV Rotary Valve, industries can now streamline their bulk material handling processes and enhance productivity.

Read More

Latest Updates and News from the Leading Online Gaming Platform

Steam Valve is a leading video game developer and digital distribution company that has been revolutionizing the gaming industry since its inception in 2003. The one-stop-shop for millions of gamers around the world, Steam Valve, has become the go-to platform for purchasing, downloading, and managing games.With a user base of over 120 million and counting, Steam Valve has taken the gaming industry by storm. The company has built a massive ecosystem of games that are available to purchase, download, and play across multiple devices, including PCs, Macs, and mobile devices.At the heart of the company's success is its innovative business model that has transformed the way gamers interact with their favorite games. Steam Valve introduced a feature-rich digital distribution platform that made it easier than ever for gamers to purchase and play games. Besides, the company established a developer-friendly culture that helped to grow its reach, as well as promote cross-collaboration and creativity within the gaming industry.While Steam Valve is primarily known for gaming, the company has also made great strides in expanding its product offerings to include software applications and hardware products. In 2015, the company launched Steam Link, which is a device that ties together a PC or Mac with a TV and enables users to play games on a big screen. Furthermore, the company has also been working on virtual reality (VR) and mobile gaming, which are the future of the gaming industry.Apart from its world-class products, Steam Valve prides itself on its passionate and innovative team of professionals who work tirelessly to provide users with an unmatched gaming experience. The company’s team comprises software engineers, gamers, designers, artists, and customer support representatives who are all passionate about the gaming industry, which is a testament to the company’s dedication to delivering top-notch products and services to its customers.Recently, Steam Valve has garnered a lot of negative media attention following its decision to ban a game from its platform which depicted rape and child abuse. The game, which was called ‘Rape Day’ attracted widespread condemnation from gamers and non-gamers alike, with many calling for Steam Valve to take action. The company promptly removed the game from its platform citing its commitment to building a safe and welcoming community for gamers.In conclusion, Steam Valve has become an iconic brand that has changed the gaming industry for good. The company has built a robust digital distribution platform that has made it easier than ever for gamers to access their favorite games. With its excellent products, innovative business model, and passionate team, Steam Valve is poised to continue leading the way in the gaming industry for years to come.

Read More

High-flow Rotary Airlock Valve: Advanced Features for Efficient Material Handling

Title: Enhancing Manufacturing Efficiency: The Versatile Drop Through Airlock Valve IntroductionIn manufacturing facilities and industrial processes, ensuring smooth material handling is crucial for efficient operations. One vital component that aids in this seamless transfer of bulk materials is the drop through airlock valve. Designed to optimize flow rates and prevent air leakage, this device has become an indispensable element in various industries. In this blog post, we will explore the notable features and benefits of a drop through airlock valve, shedding light on its significant role in enhancing manufacturing efficiency.Understanding the Drop Through Airlock ValveThe drop through airlock valve, sometimes referred to as a rotary airlock valve, is a fundamental component used in numerous industrial applications. Its primary function is to regulate the continuous flow of materials while maintaining a consistent pressure environment. The valve accomplishes this through a rotation mechanism that creates a seal between different sections of the production line, reducing air leakage and avoiding process disruptions.Key Features and Benefits1. Enhanced Flow Rate: One of the major advantages of the drop through airlock valve is its ability to handle high flow rates. Thanks to its sturdy construction and efficient design, it facilitates the transfer of bulk materials swiftly and smoothly from one processing stage to another. This feature proves vital in ensuring uninterrupted production and prevents potential bottlenecks.2. Preventing Air Leakage: Air leakage is a significant concern in various industrial processes, as it can negatively impact operating conditions and compromise product quality. The drop through airlock valve effectively isolates different pressure zones within the manufacturing line, minimizing air leakage. By maintaining a controlled environment, the valve ensures that products are handled with utmost care and consistency.3. Material Protection: In industries dealing with fragile or abrasive materials, preserving the integrity of the product during handling is of utmost importance. The drop through airlock valve prevents material degradation by providing a gentle transfer mechanism. Its precise engineering minimizes material damage, ensuring that the end product meets the desired quality standards.4. Versatile Application: The drop through airlock valve finds its utility across a multitude of industries. From pharmaceuticals and food processing to chemical manufacturing and agricultural sectors, this valve is adaptable to various material handling needs. Its customizable design, available in different sizes and materials, enables seamless integration into existing production lines.5. Durability and Low Maintenance: Industrial equipment needs to withstand rigorous operational demands. The drop through airlock valve boasts a robust construction, ensuring its longevity and minimizing maintenance requirements. With regular preventive care, this valve proves to be a cost-effective investment, providing reliable performance over an extended period.ConclusionFrom high flow rates to preserving material integrity, the drop through airlock valve offers a range of benefits that significantly boost manufacturing efficiency. Its ability to regulate the continuous flow of materials, prevent air leakage, and adapt to diverse industry needs makes it an indispensable component in various production lines. With its durable construction and low maintenance requirements, this valve proves to be a reliable and cost-effective solution for optimizing material handling processes.To enhance manufacturing efficiency and streamline operations, businesses should consider incorporating drop through airlock valves into their workflows. By leveraging the key features and benefits of this versatile device, industries can ensure smooth material transfers, reduce downtime, and ultimately enhance productivity.

Read More

Enhance Engine Performance with a Reliable Blow Off Valve

[Company Introduction][Company name] is an automotive technology company specializing in high-performance vehicle components and systems. We constantly strive to push the boundaries of innovation, engineering cutting-edge solutions for the automotive industry. With a team of highly skilled engineers and a commitment to excellence, we have been at the forefront of delivering exceptional performance and durability to car enthusiasts and professional racers worldwide.[News Content][City, Date] – [Company name], an industry leader in automotive technology, has recently introduced their latest product, the innovative Blow Off Valve (BOV), which promises to revolutionize the performance of turbocharged engines. With its advanced design and meticulous engineering, the BOV offers improved power delivery and enhanced vehicle dynamics, ensuring an unmatched driving experience.The Blow Off Valve is an essential component in turbocharged engines, responsible for venting excess pressure from the turbocharger's compressor when the throttle is closed. The BOV prevents compressor surge, a condition that occurs when the pressurized air has nowhere to go after the throttle plate closes, resulting in potential damage to the turbocharger. Not only does the BOV protect the turbocharger, but it also plays a significant role in enhancing engine responsiveness and overall performance.[Company name]'s BOV sets itself apart from competitors through its innovative features and state-of-the-art design. Utilizing the latest materials and manufacturing techniques, the BOV offers unparalleled durability, ensuring it can withstand the toughest racing conditions. The lightweight construction and precision engineering reduce the likelihood of leaking, providing consistent and reliable performance.Moreover, the BOV incorporates a unique adjustability feature, allowing drivers to fine-tune the response characteristics according to their preferences. This customization capability is a game-changer, as it enables drivers to optimize their vehicle's performance for different driving conditions, ranging from street driving to track racing. By tailoring the BOV's responsiveness, drivers can achieve quicker throttle response, improved power delivery, and a more engaging driving experience.The engineering team at [Company name] left no stone unturned when developing the BOV. Through extensive research and rigorous testing, they have ensured that the product meets the highest standards of quality and performance. The BOV underwent multiple simulations and real-world trials to guarantee its reliability in extreme conditions. Backed by a comprehensive warranty and exceptional customer support, [Company name] promises to deliver a product that exceeds expectations."We are thrilled to introduce our Blow Off Valve to the market," said [Spokesperson Name], the CEO of [Company name]. "It represents the culmination of months of hard work and dedication from our team. We believe that our product offers an unparalleled combination of performance, durability, and adjustability, making it a top choice for car enthusiasts and professional racers alike."With its cutting-edge technology and commitment to excellence, [Company name] continues to push the boundaries of automotive performance. The introduction of the Blow Off Valve reinforces their position as a leading innovator in the industry. Car enthusiasts and professional racers can now experience unparalleled performance and reliability, thanks to [Company name]'s latest breakthrough.About [Company name][Company name] is an automotive technology company specializing in high-performance vehicle components and systems. With a team of highly skilled engineers and a commitment to excellence, [Company name] delivers innovative solutions that enhance vehicle performance and driving experience. Their products are trusted by car enthusiasts and professional racers worldwide.For more information, please visit [website] or contact [contact details].###[Word Count: 607]

Read More