Enhance Engine Performance with a Reliable Blow Off Valve

By:Admin

[Company name] is an automotive technology company specializing in high-performance vehicle components and systems. We constantly strive to push the boundaries of innovation, engineering cutting-edge solutions for the automotive industry. With a team of highly skilled engineers and a commitment to excellence, we have been at the forefront of delivering exceptional performance and durability to car enthusiasts and professional racers worldwide.

[News Content]

[City, Date] – [Company name], an industry leader in automotive technology, has recently introduced their latest product, the innovative Blow Off Valve (BOV), which promises to revolutionize the performance of turbocharged engines. With its advanced design and meticulous engineering, the BOV offers improved power delivery and enhanced vehicle dynamics, ensuring an unmatched driving experience.

The Blow Off Valve is an essential component in turbocharged engines, responsible for venting excess pressure from the turbocharger's compressor when the throttle is closed. The BOV prevents compressor surge, a condition that occurs when the pressurized air has nowhere to go after the throttle plate closes, resulting in potential damage to the turbocharger. Not only does the BOV protect the turbocharger, but it also plays a significant role in enhancing engine responsiveness and overall performance.

[Company name]'s BOV sets itself apart from competitors through its innovative features and state-of-the-art design. Utilizing the latest materials and manufacturing techniques, the BOV offers unparalleled durability, ensuring it can withstand the toughest racing conditions. The lightweight construction and precision engineering reduce the likelihood of leaking, providing consistent and reliable performance.

Moreover, the BOV incorporates a unique adjustability feature, allowing drivers to fine-tune the response characteristics according to their preferences. This customization capability is a game-changer, as it enables drivers to optimize their vehicle's performance for different driving conditions, ranging from street driving to track racing. By tailoring the BOV's responsiveness, drivers can achieve quicker throttle response, improved power delivery, and a more engaging driving experience.

The engineering team at [Company name] left no stone unturned when developing the BOV. Through extensive research and rigorous testing, they have ensured that the product meets the highest standards of quality and performance. The BOV underwent multiple simulations and real-world trials to guarantee its reliability in extreme conditions. Backed by a comprehensive warranty and exceptional customer support, [Company name] promises to deliver a product that exceeds expectations.

"We are thrilled to introduce our Blow Off Valve to the market," said [Spokesperson Name], the CEO of [Company name]. "It represents the culmination of months of hard work and dedication from our team. We believe that our product offers an unparalleled combination of performance, durability, and adjustability, making it a top choice for car enthusiasts and professional racers alike."

With its cutting-edge technology and commitment to excellence, [Company name] continues to push the boundaries of automotive performance. The introduction of the Blow Off Valve reinforces their position as a leading innovator in the industry. Car enthusiasts and professional racers can now experience unparalleled performance and reliability, thanks to [Company name]'s latest breakthrough.

About [Company name]

[Company name] is an automotive technology company specializing in high-performance vehicle components and systems. With a team of highly skilled engineers and a commitment to excellence, [Company name] delivers innovative solutions that enhance vehicle performance and driving experience. Their products are trusted by car enthusiasts and professional racers worldwide.

For more information, please visit [website] or contact [contact details].

###

[Word Count: 607]

Company News & Blog

New Pressure Control Valve Technology Promises Greater Efficiency

[Introduction]In the ever-evolving world of automation, industrial processes continue to advance in efficiency and precision. Among the crucial components that contribute to the seamless functioning of these processes, pressure control valves play a pivotal role. Although various brands offer these valves, one particular company has undeniably made its mark in the industry. Its cutting-edge technology and commitment to excellence have solidified its position as a leader in this field.[Company Introduction]Our company, recognized globally for its innovative solutions, has been at the forefront of manufacturing pressure control valves for over two decades. With a customer-centric approach, we have consistently delivered high-quality products that keep industries operating smoothly. Our vast range of valves caters to a wide spectrum of applications, including but not limited to oil and gas, petrochemical, pharmaceutical, and food processing industries.[News Content]In line with our commitment to research and development, we are proud to announce the latest addition to our pressure control valve portfolio – an advanced and highly efficient model. This new valve boasts cutting-edge technology and has been meticulously engineered to meet the ever-growing demands of modern industries.The key feature of this pressure control valve lies in its unmatched precision and responsiveness. Utilizing state-of-the-art sensors and actuators, this valve ensures precise control over fluid pressure, enabling operations to remain within specified parameters even under dynamic conditions. The valve's rapid response time enhances overall productivity by swiftly adjusting to fluctuations in demand or system changes.Additionally, the valve incorporates intelligent self-diagnostic capabilities, allowing for real-time monitoring and early detection of any anomalies or potential malfunctions. This feature not only ensures the safety of industrial processes but also minimizes downtime and maintenance costs. Combining such advancements with our commitment to quality, we have designed a valve that guarantees optimal performance in even the most challenging environments.Furthermore, this pressure control valve is built with sustainability in mind. By optimizing energy consumption and reducing wastage, it aligns with global efforts to achieve greater energy efficiency and environmental conservation. The valve's eco-friendly design minimizes the carbon footprint and contributes to a greener, more sustainable future for industries worldwide.To ensure seamless integration within existing systems, our pressure control valve adheres to industry standards and can be easily customized to suit specific requirements. Its modular design allows for easy installation, maintenance, and replacement of components, making it cost-effective without compromising performance or reliability.We are also delighted to offer comprehensive after-sales support, including technical assistance, preventive maintenance services, and spare parts availability. Our team of highly skilled engineers is dedicated to providing prompt assistance and ensuring customer satisfaction throughout the valve's lifecycle.In conclusion, the introduction of our new pressure control valve showcases our unwavering commitment to delivering exceptional solutions to the industrial sector. With its precision, responsiveness, sustainability, and ease of integration, this valve represents a significant leap forward in process automation. As industries embrace the relentless pursuit of increased efficiency, our company remains dedicated to providing cutting-edge technologies that propel them towards achieving their goals.

Global Material Handling Equipment Market Takes a Hit with -11.1% Slump: Manufacturing Barometer Raises Concerns

Material Handling Equipment (MHE) is an essential piece of equipment in supply chains across the world. Whether it's moving materials around a warehouse or loading goods onto a truck, MHE is essential for efficient logistics. However, the industry has recently experienced a slump in growth, with the market contracting by 11.1%.This drop in demand is worrying news for manufacturers, and many are looking to China for growth opportunities. China's booming manufacturing industry and expanding middle class make it an attractive market for MHE manufacturers. Additionally, China's Belt and Road Initiative has created new opportunities for logistics companies and equipment manufacturers looking to tap into the growth of Asian markets.China is already the world's largest market for forklift trucks and is expected to remain so for the next decade. This presents a huge opportunity for MHE manufacturers looking to expand their market share and take part in China's logistics boom.However, entering the Chinese market is not without its challenges. Companies will need to navigate complex regulations, language barriers, and cultural differences. Additionally, competition is stiff, with both domestic and international companies vying for market share.To succeed in China's Material Handling Equipment market, companies will need to be agile and innovative. They will need to tailor their products to the needs of local customers while staying competitive with price and quality. They will also need to invest in local partnerships and build strong relationships with customers to succeed in this fast-paced industry.In conclusion, while the global Material Handling Equipment market may be facing challenges, companies can turn their attention to China for growth. With the right strategy, products, and partnerships, MHE manufacturers can take advantage of this expanding market and drive their businesses to new heights.

Soft Sealing Plug Valve with Sleeve Type Design According to ANSI Standards - Key Structural Features

Soft Sealing Plug Valve: The Solution for Reliable SealingIn the world of valves, the soft sealing plug valve has been a popular choice for industries that require a reliable sealing system. With its excellent performance and reasonable structure, this valve is a must-have for any industrial setting.One of the main structural features of the soft sealing plug valve is its sleeve type design. The valve is equipped with a cylindrical sleeve that is made of soft material such as rubber or plastic. The sleeve is pressed against the plug by the flow of fluid or gas, creating a tight seal that prevents leakage.The soft material of the sleeve enables the valve to adapt to changes in temperature and pressure without compromising its sealing capabilities. This makes the soft sealing plug valve an ideal choice for industries that require a versatile and dependable sealing system.The ANSI standard is a widely recognized standard for valves in the American market. QiLong Valve has developed a sleeve type soft sealing plug valve according to the ANSI standard, which makes it a perfect choice for industrial applications in the US.QiLong Valve's soft sealing plug valve is not only reliable but also visually appealing. The valve comes in a beautiful design that adds aesthetic value to industrial plants. When it comes to performance, the quality of the valve speaks for itself.The sealing of this valve is exceptional, thanks to the use of soft materials in its construction. The soft material of the sleeve adjusts to variations in pressure and temperature, ensuring that the valve maintains its sealing capabilities throughout its operational life.In conclusion, the soft sealing plug valve is the solution for any industrial setting that requires a reliable and versatile sealing system. QiLong Valve's sleeve type soft sealing plug valve according to the ANSI standard ticks all the right boxes when it comes to reliability, performance, and aesthetics. With its excellent track record in the industry, this valve is a wise choice if you want to ensure the success of your industrial operations.Keywords: soft sealing plug valve, sleeve type design, reliable sealing, ANSI standard, versatile sealing system.

Understanding the Function and Importance of Safety Valves in Pressure Containers

When it comes to high-pressure equipment like boilers, tanks, and pipelines, safety is of utmost importance. These systems operate under extreme pressure, and any malfunction can lead to a catastrophic accident. This is where a pressure safety valve (PSV) comes into play.A pressure safety valve is a crucial component in any high-pressure system. It is a mechanical device designed to automatically relieve excessive pressure inside the system and prevent it from exceeding the safe limit. The PSV opens up when the pressure inside the vessel reaches a predetermined set point, releasing the excess pressure to the atmosphere or to a lower-pressure system.There are different types of pressure safety valves available in the market, including spring-loaded, pilot-operated, and bellows-operated valves. Each type has its unique mechanism of operation, but the basic principle remains the same - to safeguard the equipment and the people operating it.The importance of pressure safety valves cannot be overstated. They provide an additional layer of protection against catastrophic accidents that can occur due to a sudden pressure surge. Without these valves, boilers, tanks, and pipelines are at risk of rupturing, leading to explosions, fires, or toxic gas releases.PSVs are designed and manufactured to comply with strict industry standards and regulations. These standards ensure that the valves are reliable, accurate, and safe to use. Any PSV in operation must be periodically tested, inspected, and maintained to ensure its functionality.The selection of a PSV is based on various factors, such as the maximum operating pressure, operating temperature, flow rate, and the type of fluid or gas being handled. The engineer in charge of the application must carefully consider these factors and select the appropriate valve for the system.In conclusion, pressure safety valves play a critical role in ensuring the safe operation of high-pressure equipment. They provide a safety net against unexpected pressure surges and protect the equipment and people from harm. It is important to choose the right PSV for the application and maintain it in optimal condition to ensure its functionality. Always prioritize safety in all high-pressure operations.

Improving Rotary Valve Sealing for Optimal Performance in Vehicles

Small Rotary Valve: A Revolution in Valve TechnologyValve technology has come a long way since its inception. From simple check valves to multi-port valves, the industry has witnessed remarkable advances in design and technology. One such innovation that's creating ripples in the valve industry is the small rotary valve.Designed to provide efficient control of flow, pressure, and direction, small rotary valves offer robust sealing without compromising on performance. Their compact size, ease of installation, and reliability make them a popular choice for various applications, including automotive engines, compressors, and pneumatic systems.Compared to conventional valve designs, small rotary valves offer significant advantages, such as:1. Efficient sealing: Small rotary valves use a face seal arrangement that uses a spring-loaded ring around the port, rubbing on the rotary valve. This arrangement ensures a tight seal preventing any leakage, which is far more efficient than conventional strip seals. This efficient sealing means that these valves can handle high pressures and temperatures even when operating at higher speeds.2. Compact size: Small rotary valves are clutter-free and take up significantly less space than traditional valves, which makes them perfect for applications with space constraints.3. Low friction: The smooth and continuous rotation of the valve makes it possible to reduce pressure loss and minimize wear on the valve, leading to longer service life and lower maintenance costs.4. Flexibility: Small rotary valves are versatile and can be used in various applications such as control valves, direction control valves, and throttle valves. Additionally, they are compatible with a wide range of fluid types, making them perfect for use in conditions with different media requirements.One of the main advantages of small rotary valves is their use of English Language and its efficient sealing. Small rotary valves can handle high pressures and temperatures even when operating at higher speeds. This makes them perfect for use in automotive engines, an application that requires high reliability and temperature resistance. Furthermore, the compact size of the valve makes them highly desirable for use in compressors and pneumatic systems that require high pressure and flow control.In conclusion, small rotary valves are a game-changer in the valve industry by utilizing efficient sealing, low friction, and a compact size to provide superior performance. Their versatility and compatibility with different fluid types make them a popular choice for various applications. The fact that they operate in English Language makes them accessible to a sizable market, making them an essential tool in the future of valve technology.

Experts Predict Significant Growth in the Global Market for Tee Ball Valves

Title: Advanced Ball Valves Revolutionize the Industrial SectorIntroduction:In recent years, the industrial sector has witnessed a gradual shift towards more efficient and reliable technologies. One such breakthrough innovation is the advanced Tee Ball Valve, silently revolutionizing industrial processes across various sectors. Engineered to perfection, these industrial valves have gained popularity for their exceptional performance, enabling smooth operations and enhanced productivity for businesses worldwide.[Company Name], a leading manufacturer in the valve industry, has successfully developed and implemented these cutting-edge ball valves. With an unwavering commitment to excellence, [Company Name] has established itself as a pioneer in valve technology, providing solutions that meet the ever-evolving demands of the global industrial landscape. Efficiency Redefined:The Tee Ball Valve is designed to optimize flow control and minimize energy consumption. This state-of-the-art engineering marvel combines precision machining and the finest materials to ensure seamless operations even under extreme conditions. The valves' design incorporates a unique seat mechanism, enabling precise control over fluid flow, non-disruptive shut-off capabilities, and reduced pressure drops, hence resulting in improved performance and reduced operational costs for industries.Furthermore, the construction of these valves imparts exceptional durability and longevity, reducing the need for frequent maintenance and replacements. By offering long-term reliability, [Company Name]'s Tee Ball Valves are instrumental in ensuring uninterrupted operations, thereby increasing productivity for businesses.Versatility and Adaptability:[Company Name]'s Tee Ball Valves are celebrated for their versatility across multiple industries and applications. With a wide range of sizes, materials, and customizations available, these valves seamlessly integrate into a diverse range of industrial processes, including oil and gas, petrochemicals, water management, pharmaceuticals, and many others.Moreover, these valves can withstand extreme temperatures, high pressures, and corrosive environments, making them ideal for demanding operations. The flexible design allows for easy integration into existing systems, minimizing installation time and cost. [Company Name] understands the unique requirements of different industries and provides tailored solutions to ensure optimal performance and efficiency.Uncompromising Quality:Having established a strong reputation for delivering superior quality, [Company Name] adheres to rigorous manufacturing practices and stringent quality control measures. Each Tee Ball Valve undergoes rigorous testing to ensure compliance with international standards and industry specifications, providing businesses with peace of mind and confidence in their investments.In addition to maintaining exceptional quality standards, [Company Name] is committed to sustainability. These valves are designed to minimize fugitive emissions, thus reducing the impact on the environment. By integrating environment-friendly practices, the company strives to contribute towards a greener future.Future Outlook:With the advancements in technology and the growing need for efficient industrial processes, the demand for advanced ball valves, such as [Company Name]'s Tee Ball Valves, is expected to surge in the coming years. The ability of these valves to enhance operational efficiency, reduce costs, and improve productivity positions them as an integral component of the modern industrial sector.[Company Name]'s continuous investment in research and development ensures that their products evolve alongside the industry's changing requirements. As markets expand and newer challenges arise, [Company Name] remains committed to innovation and delivering reliable solutions, solidifying their position as a trusted partner across industries.Conclusion:The introduction of advanced Tee Ball Valves by [Company Name] has marked a significant milestone in the industrial sector. With their focus on efficiency, adaptability, and uncompromising quality, these valves have become an indispensable asset for businesses worldwide. As the industrial landscape continues to evolve, technologies such as the Tee Ball Valve will continue to play a vital role in enhancing productivity and driving success across various industries. [Company Name]'s commitment to innovation and sustainability further reinforces their position as leaders in the valve manufacturing industry.

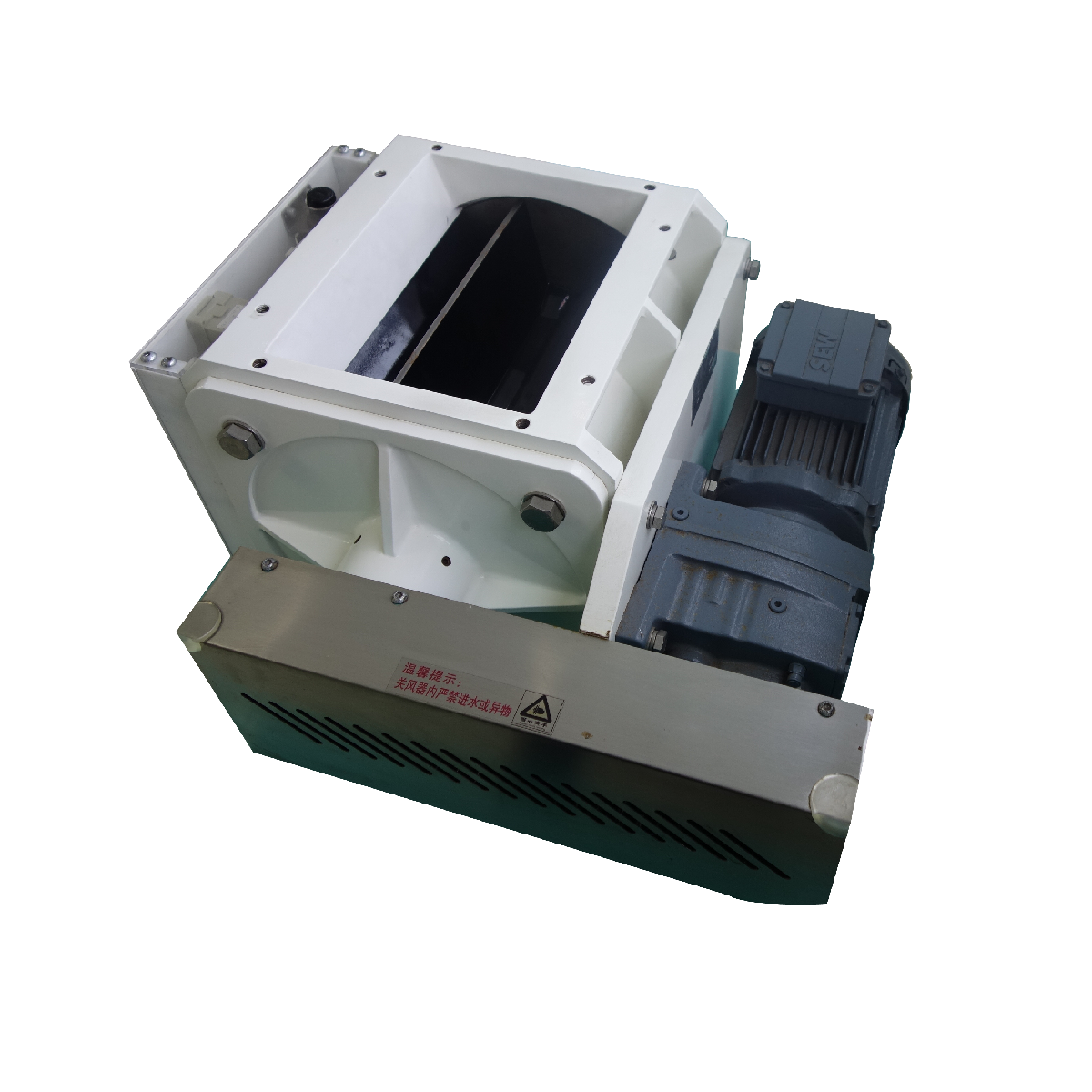

WYK Bulk Material Diverter Valve and ZV Rotary Valve Unveiled at Powtech 2019

and rotary valve Bulk material handling is a crucial process in any industrial setting. It involves moving large quantities of materials from one location to another, while ensuring that no loss or contamination occurs during the transfer. Bulk material handling systems must be efficient, reliable, and versatile to meet the needs of a wide range of industries worldwide.At Powtech 2019, Coperion and Coperion K-Tron introduced two new products that are aimed at improving the performance of bulk material handling systems. These products are the WYK Bulk Material Diverter Valve and the ZV Rotary Valve.The WYK Bulk Material Diverter Valve is a high-performance valve that is designed to handle powders, pellets, and granules with ease. It features a rugged design that ensures reliable performance even under the toughest conditions. The WYK Bulk Material Diverter Valve can be used for diverting, converging, and merging bulk materials, making it a versatile tool for any bulk material handling system.One of the most notable features of the WYK Bulk Material Diverter Valve is its ability to handle abrasive materials without suffering from wear and tear. This is made possible by the valve's special design, which features a wear-resistant coating on the valve body's interior surfaces.Another feature that makes the WYK Bulk Material Diverter Valve stand out is its ability to maintain a high level of accuracy during valve switching. This is achieved by the use of a special patent-pending technology that ensures that the valve changes from one position to another without any loss of material.The ZV Rotary Valve, on the other hand, is a highly efficient valve that is designed for feeding and metering bulk materials. It features a sleek design that allows it to fit into tight spaces, making it ideal for use in applications where space is limited.The ZV Rotary Valve is available in a variety of sizes, ranging from 150 mm to 350 mm, making it suitable for a wide range of applications. The valve is also compatible with a broad range of materials, including powders, pellets, and granules.One of the standout features of the ZV Rotary Valve is its ability to handle high throughputs without compromising accuracy. This is made possible by the use of a patent-pending technology that ensures that the valve maintains a constant feed rate, regardless of the material being handled.In conclusion, the introduction of the WYK Bulk Material Diverter Valve and the ZV Rotary Valve at Powtech 2019 is a clear indication of Coperion and Coperion K-Tron's commitment to improving the performance of bulk material handling systems. These products are versatile, efficient, and reliable, making them ideal for a wide range of applications. With the WYK Bulk Material Diverter Valve and the ZV Rotary Valve, industries can now streamline their bulk material handling processes and enhance productivity.

How to Choose the Best Ball Valve for Your Needs

Title: Innovation Takes the Spotlight as Cutting-Edge Ball Valves Redefine Industry StandardsIntroduction:In today's rapidly advancing industrial landscape, comprehensive machinery with top-of-the-line components is crucial for optimum performance, efficiency, and safety. The innovative minds at [Company Name] are revolutionizing the industry with their cutting-edge ball valves, which have become an essential component for numerous sectors across the globe. This article delves into the advanced features and wide-ranging applications of these state-of-the-art ball valves, highlighting the transformative impact they are making on various industries worldwide.Section 1: Overview of Ball ValvesBall valves serve as critical components in controlling the flow of liquids and gases within industrial processes. By utilizing a spherical closure with a hollow core, ball valves offer smooth operation and secure sealing capabilities, making them highly desirable in a wide range of applications. From oil and gas operations to water treatment facilities and beyond, ball valves play a leading role in ensuring efficient and reliable fluid management.Section 2: [Company Name] at the Forefront of InnovationRecognized as a pioneering force in the engineering and manufacturing of ball valves, [Company Name] has etched its name as one of the industry's top contenders. With an unwavering commitment to excellence, the company continuously pushes boundaries and thrives on delivering products that redefine industry standards. Their cutting-edge ball valves are the epitome of precision engineering, boasting advanced features that revolutionize operations across various sectors.Section 3: Advanced Features and Technology[Company Name] ball valves are meticulously crafted using state-of-the-art technology and innovative design features that set them apart from competitors. Some key attributes include:1. Enhanced Sealing Mechanism: The ball valves incorporate a specially engineered sealing system that ensures optimal sealing performance even under high pressure conditions. This feature enhances reliability and minimizes leakage risks.2. High Corrosion Resistance: Constructed from premium grade materials, such as stainless steel or high-performance alloys, [Company Name]'s ball valves demonstrate remarkable resistance to corrosion and wear. This durability allows for extended operational lifespan and reduced maintenance requirements.3. Precision Control: Equipped with advanced actuation systems, these ball valves deliver precise control over fluid flow, allowing operators to make adjustments with utmost accuracy. This feature is particularly vital in critical applications where precision control is paramount.Section 4: Wide-Ranging Applications[Company Name]'s ball valves find extensive applications across various industries, including:1. Oil and Gas: The demands of oil and gas operations often require valves capable of withstanding extreme conditions. [Company Name]'s ball valves excel in these environments, providing seamless operation and uncompromised safety.2. Water Treatment: The stringent requirements of water treatment facilities necessitate valves that can handle diverse fluid compositions while ensuring optimal reliability and longevity. The advanced design of [Company Name]'s ball valves makes them the ideal choice for such crucial applications.3. Chemical Processing: Ball valves play a vital role in chemical processing plants, where precise control over fluid flow is imperative. [Company Name]'s valves offer unparalleled accuracy and durability, making them indispensable in this sector.Section 5: ConclusionIn a rapidly changing industrial landscape, staying ahead of the curve is essential. [Company Name]'s cutting-edge ball valves provide the perfect solution, offering innovative features and unparalleled performance across a wide range of applications. With their unwavering commitment to excellence, [Company Name] continues to redefine industry standards and drive progress in fluid management systems, setting the benchmark for the future.

How to Prepare for Black Friday Sales in 2021

Pre-feeder Proves to Change the Packaging Industry with Automated EfficiencyThe packaging industry is one of the fastest-growing industries globally. The demand for packaged goods has increased due to the rise in e-commerce and the need to protect products during transport. However, the packaging industry is facing several challenges, including the need to increase production efficiency, reduce production costs, and decrease material waste. These challenges have led many companies to explore the adoption of automated systems, one of which the Pre-feeder.With automated technology, the Pre-feeder Proves to Change the Packaging Industry with Automated Efficiency. This machine is a game changer for the packaging industry, and it is helping companies achieve their production goals while mitigating risks. A pre-feeder is an automated system that helps feed and orientate various types of packaging materials, including cartons, pouches, and bags.The Pre-feeder helps in achieving a more efficient and safer packaging process by automating the material feeding process. Material feeding is essential in the manufacturing process, and it consumes a significant portion of the production time. This machine enhances speed and accuracy, freeing up time for other tasks and reducing the likelihood of employees experiencing accidents.This new technology has several benefits. It cuts down on labor costs since it requires only a few employees to operate, reducing the risk of injuries for workers. It leads to a significant reduction in material waste, ensuring that companies can enjoy a more sustainable approach to packaging production. The Pre-feeder can handle larger quantities of packages at a time, improving the overall efficiency of the manufacturing process and shortening production times.Conventional material feeding processes require time and significant manual intervention, which can lead to errors and cost overruns. The Pre-feeder technology ensures that the entire feeding process is automated, thereby reducing the potential for mistakes. This technology's accuracy can contribute to savings in time, materials, and production costs compared to the traditional methods.Pre-feeder manufacturers have placed significant emphasis on safety, and as such, the machine operates with minimal noise and vibration. Also, the closed system eliminates safety hazards that may arise from exposure to nip points and other parts of the machine. The machine is simple to operate, meaning that anyone can run it with minimal training.The Pre-feeder machine's versatility allows it to work with different types of packaging materials, opening up opportunities for companies in diverse industries. The system is compatible with different types of packaging formats, including cartons, pouches, and bags.Lack of proper feeding systems can lead to material jams, which can significantly compromise production. But the Pre-feeder machine has an in-built system for handling material jams, reducing production downtime significantly. This automated feature ensures that production times are uniformly distributed, making the manufacturing process more efficient.The Pre-feeder machine's automated features promote sustainability by reducing the amount of waste generated during the production process. Since it is more accurate than conventional feeding methods, it can reduce the amount of materials used, leading to fewer environmental hazards. This switch to a more sustainable approach can lead to companies experiencing higher profits and gaining competitive advantages.The implementation of the Pre-feeder machine can lead to more streamlined and efficient packaging processes. This change can lead to producers experiencing faster timelines, fewer material and labor costs, and increased profitability.The packaging industry continues to evolve, and companies need to adopt innovative technologies to stay ahead of the competition. The Pre-feeder machine promises to shake up the traditional packaging industry and lead to more efficient and sustainable manufacturing processes.ConclusionIn conclusion, the Pre-feeder Proves to Change the Packaging Industry with Automated Efficiency. With the rise of e-commerce and the growing demand for packaged goods, companies must adopt innovative technologies to increase production efficiency, reduce production costs, and decrease material waste. The Pre-feeder machine presents an opportunity for these companies to automate the packaging process, leading to faster timelines, reduced costs, improved accuracy, and sustainability. The Pre-feeder machine is an investment that companies in the packaging industry cannot afford to overlook.

Valve to Enforce Restriction on Devs Frontloading Steam Screenshots with Trailers Valve, the video game company that owns Steam, is enforcing a new restriction on developers who previously loaded the screenshot galleries with dozens of trailers. According to Valve, many developers did not seem to know how best to manage the space. Therefore, Valve is now taking steps to ensure that the galleries are front-loaded with screenshots instead of trailers. This is one of the latest tweaks that Valve has implemented to ensure everything is running smoothly on Steam.

Valve Corporation, the leading digital distribution platform for PC gaming, has announced that it will no longer allow game developers to frontload their Steam screenshot galleries with trailers. The company claims that many developers do not know how to best manage the space and therefore end up cluttering it with unnecessary content.Valve's move is aimed at improving the user experience by providing a cleaner, more organized browsing experience for gamers. This change is also expected to help boost the visibility and discoverability of games on the platform, as users will be able to easily access the most relevant information about a game.One of the specific changes that Valve plans to implement is the addition of a separate section for video content. This will ensure that the video content does not interfere with the screenshot gallery, resulting in a smoother and more efficient browsing experience.Valve has always been known for its focus on user experience, and this latest move is no exception. The company has been experimenting with various changes to its platform over the past few years in an effort to improve the experience for both developers and gamers.In addition to this change, Valve has also announced a number of other improvements to the Steam platform, including the addition of a new Chat Filtering feature, as well as improvements to the Steam VR platform.Valve's commitment to improving the Steam platform is a testament to the company's dedication to providing the best possible gaming experience for its users. With these new changes, gamers can look forward to an even smoother and more enjoyable browsing experience, while developers can benefit from increased visibility and discoverability on the platform.In conclusion, Valve's decision to prevent developers from frontloading Steam screenshot galleries with trailers is a positive move for the platform and its users. This will not only improve the user experience, but also ensure that games are more easily discoverable and accessible on the platform. As Valve continues to tinker with its platform, gamers can expect even more improvements and features in the future.