Pneumatic Conveying Systems for Flour: A Comprehensive Guide

By:Admin

In the fast-paced and ever-evolving food industry, a reliable and efficient method of transporting flour is crucial for maintaining productivity and ensuring the quality of the final product. With the introduction of a cutting-edge flour pneumatic conveying solution by {Company}, the industry is set to experience a significant transformation.

{Company} is a renowned leader in the design and manufacture of advanced material handling systems. With a strong focus on innovation and customer satisfaction, the company has consistently delivered state-of-the-art solutions to a wide range of industries, including food processing, pharmaceuticals, and chemical manufacturing.

The recently launched flour pneumatic conveying system has been specifically designed to address the challenges faced by flour producers and processors. Traditionally, the transportation of flour has been a labor-intensive and time-consuming process, often involving manual handling and the use of outdated equipment. This not only slows down the production process but also increases the risk of contamination and product loss.

The pneumatic conveying solution offered by {Company} utilizes the latest technology to streamline the transportation of flour, ensuring a seamless and efficient workflow. By harnessing the power of air pressure, the system is able to move large quantities of flour with ease, minimizing the need for manual intervention and reducing the risk of product degradation. This ultimately leads to higher productivity, lower operating costs, and improved product quality.

One of the standout features of {Company}'s pneumatic conveying system is its ability to handle a wide range of flour types, including wheat, corn, and rice flour. The system is also highly customizable, allowing for tailored solutions to suit the specific requirements of each client. This flexibility, coupled with the system's impressive performance, has garnered widespread attention and positive feedback from industry professionals.

In addition to its technical prowess, {Company} has also distinguished itself through its commitment to sustainability and environmental responsibility. The flour pneumatic conveying system is designed to minimize energy consumption and emissions, making it a greener alternative to traditional transportation methods. This aligns with {Company}'s core values of promoting eco-friendly practices and reducing its carbon footprint.

The impact of {Company}'s flour pneumatic conveying solution extends beyond the company itself and has the potential to revolutionize the food industry as a whole. By offering a more efficient and reliable method of transporting flour, the system has the power to enhance the overall productivity and competitiveness of food processing companies. This, in turn, can lead to improved supply chain dynamics and consumer satisfaction.

In response to the launch of the flour pneumatic conveying system, industry experts have expressed optimism about its potential to drive positive change. Many have praised {Company} for its forward-thinking approach and dedication to delivering high-quality solutions that address real-world challenges. It is anticipated that the system will set a new standard for flour transportation and inspire further innovations in the food industry.

Looking ahead, {Company} remains committed to pushing the boundaries of material handling technology and continuously raising the bar for industry standards. With its track record of excellence and a strong focus on customer collaboration, the company is well-positioned to continue making a meaningful impact on the food industry and beyond.

In conclusion, the introduction of {Company}'s flour pneumatic conveying system marks a significant milestone in the evolution of the food industry. By offering a more efficient, reliable, and sustainable method of transporting flour, the system has the potential to revolutionize food processing and drive positive change across the supply chain. As {Company} continues to lead the way in material handling innovation, the future looks brighter for food producers and consumers alike.

Company News & Blog

Latest News and Updates on the Indian Economy

In today’s era, where technology has made its way to every aspect of our lives, AI and automation have become the game changers. In the world of news and media, the trend of automatic news updates and analysis has been gaining popularity lately, thanks to the impressive advancements in AI.The introduction of automatic news and updates from the news media websites has brought about significant changes in the way news is presented, processed and analyzed. One such popular platform that offers automatic news and updates is The Economictimes.com (need remove brand name). This platform provides customized, fully-automated updates on various business, economic and financial news worldwide while ensuring the information is concise and accurate.The primary aim behind offering automated news updates is to make daily news consumption more efficient, accessible, and tailored to the audience's interests. With the help of AI-powered algorithms, news is delivered to people in real-time as soon as it happens. The platform is designed to cluster news into various categories - including business, economy, technology, sports, entertainment - and present it in a clean and well-organized format. This way, users can read only the stories that interest them, rather than sifting through irrelevant content.The platform's use of AI and automation is not restricted to just news distribution. Automatic news analysis using AI technology is also a significant aspect of The Economictimes.com (need remove brand name). By analyzing data from multiple sources, the platform can provide insightful analysis and predictions about market fluctuations, business trends, and consumer behavior. This way, the site can help users make informed decisions and stay updated on the key factors that could affect their lives and businesses.The efficiency and accuracy of automatic news updates are highly beneficial, especially in today's fast-paced world, where staying updated constantly is essential. With the help of AI technology, The Economictimes.com (need remove brand name) provides users with a powerful tool to stay up-to-date without having to spend a lot of time browsing through multiple news sites. Users can customize the news feeds according to their interests and get updates on the go, saving valuable time and enhancing their productivity.But what is the future of automatic news updates? Considering the growing popularity of AI and automation in the field of news and media, we can safely assume that it is here to stay. AI-powered news and analysis offer countless benefits, which are hard to ignore. Furthermore, as the technology advances, we can expect to see more sophisticated features that are more customizable, insightful, and efficient.In conclusion, automatic news and updates powered by AI and automation represent the future of news and media. Platforms like The Economictimes.com (need remove brand name) are leading the way in this trend, providing users with accurate, efficient and tailored news and analysis in real-time. The increasing popularity and adoption of AI-powered news and analysis only prove the potential of this technology to revolutionize the way we consume and process news. As we welcome this new era of news and media, we can look forward to the exciting developments that technology will bring, making our lives more seamless, productive and informed.

The Latest Innovations in Hydraulic Control Valves: A Comprehensive Guide

Hydraulic Control Valve: Revolutionizing the Fluid Control IndustryThe fluid control industry has been constantly evolving over the years, and with technology advancements, it has undergone tremendous changes. One such breakthrough product is the Hydraulic Control Valve (HCV). HCVs are used to regulate the flow of hydraulic fluids in machines, equipment, and other industrial applications. These valves have proved to be a game-changer in the fluid control industry as they have made it easier to regulate and control the flow of fluids with utmost accuracy.HCVs come in various types of valves, ensuring that there is always a valve suitable for every fluid control need. The valves are designed to control the flow of fluids according to a predetermined pattern so that the machine or equipment operates at optimum performance. This is achieved by controlling fluid pressure through using the valve to regulate the amount of fluid passing through the hydraulic line to the operational unit.Hydraulic Control Valve Product FeaturesHCVs are known for their remarkable efficiency and accuracy in regulating the flow of fluids. They have a variety of features that make them a must-have for any industrial fluid control system. Some of the features of HCVs include:1. Durability:HCVs are manufactured using high-quality materials to ensure that they are durable and function effectively over extended periods.2. Flexibility:HCVs are designed to fit a wide range of applications without affecting their accuracy or effectiveness.3. Reliability:HCVs are reliable in controlling the flow of fluids as they have fewer moving parts that are prone to wear and tear.4. Accurate Flow Control:HCVs are exceptionally precise in controlling the flow of fluids to ensure that the machine operates at the appropriate functioning levels.Company IntroductionOur company operates in the fluid control industry, and we have been at the forefront of technological advancements in the industry. We are dedicated to providing quality products to our customers that are value-driven and designed to meet their specific needs.Our innovative HCVs have been successful in revolutionizing the industry, and we are committed to ensuring that they are continually evolving to meet the ever-changing industry needs.Our HCVs have been tested and proven to be effective in a wide range of applications. They can be used in various industries, including the marine, oil, and gas, and mining industries. We pride ourselves on our commitment to delivering reliable and value-driven products to our customers.Our company has a team of qualified professionals who work tirelessly to design, develop, and improve our HCV technology. We leverage the latest technological advancements and innovations to offer our customers quality HCVs that are efficient and reliable.ConclusionThe Hydraulic Control Valve is a product of cutting-edge technology that has transformed the fluid control industry. It has proven to be highly efficient, reliable, and flexible, making it an essential component in the machines and equipment used in various industries.As a company, we recognize the importance of providing our customers with innovative and value-driven products to meet their specific needs. Our HCVs are designed to cater to various applications, ensuring that we deliver quality products that are both reliable and cost-effective.We invite our customers to explore our range of HCVs, where they will find solutions that meet their exact fluid control needs. We are dedicated to meeting our customers' needs by providing them with unrivaled service and support. We continue to invest heavily in research and development to come up with more innovative products that will revolutionize the fluid control industry even further.

Gray Striped Cat with Dilute Tortoiseshell Coat Missing in West End

Lost Cat, Gray Striped (Dilute Tortoiseshell) Cat in West EndWEST END, NORTH CAROLINA - A family in West End is desperately searching for their beloved cat, who disappeared from their home earlier this week. The gray-striped dilute tortoiseshell cat, named Bella, has been missing since Wednesday, and her owners are asking for the community's help to find her.Bella is a three-year-old female cat with gray and white fur, green eyes, and a distinctive striped pattern. She is a friendly and loving cat who enjoys cuddles and playtime with her family. Her owners say she has never gone missing before and they are very worried about her.She's a sweet and gentle cat, who loves nothing more than curling up on our laps and purring, said Bella's owner, Jane Smith. We are heartbroken that she has gone missing and we are hoping that someone in the community can help us find her.Bella was last seen at her home on Wednesday morning, and her owners believe she may have wandered off to explore the surrounding area. They have searched the local streets and posted flyers around the neighborhood, but so far, there have been no sightings of the missing cat.We've been out every day, calling her name and searching for her, said Smith. We know she's out there somewhere, and we just want to bring her home safe and sound.The Smith family has enlisted the help of local animal shelters and rescue groups in their search for Bella, and they are also appealing to anyone who may have seen her to come forward. They have set up a dedicated phone number and email address for anyone with information about the missing cat to get in touch.We're hoping that someone in the community has seen her or knows where she is, said Smith. We are willing to offer a reward for her safe return, and we are just praying that she comes home soon.Anyone with information about Bella's whereabouts is urged to contact the Smith family at [INSERT PHONE NUMBER] or [INSERT EMAIL ADDRESS]. The family has also shared photos of Bella on social media in the hope that they can reach a wider audience and find their missing pet.For many families, pets are an important part of their lives, providing companionship, comfort, and joy. However, losing a pet can be a devastating experience, and it's important to take immediate action to try and find them. Bella's owners are doing everything they can to locate their missing cat, and they are grateful for the support of the local community in their efforts.At times like these, it's comforting to know that there are kind and compassionate people in our community who are willing to help us, said Smith. We are hopeful that the power of social media and word of mouth will help us find Bella and bring her home to us where she belongs.As a company that values the well-being of pets, we encourage all pet owners to take steps to keep their animals safe and secure. This includes ensuring that they are microchipped and wearing identification tags, as well as keeping them indoors at night and supervising them when they are outside. By working together as a community, we can help ensure that all pets are able to live happy and healthy lives with their owners.

Discover the Benefits of a High-Quality Stainless Steel Feeder Valve

Stainless Steel Feeder Valve: Ensuring Precision and Durability in Industrial EnvironmentsWith a commitment to providing top-quality products for various industries, XYZ Corporation has introduced its latest innovation, the Stainless Steel Feeder Valve. Designed with precision and built to last, this cutting-edge valve is set to revolutionize the way industrial processes operate. Let us delve deeper into the features and benefits of this groundbreaking product.The Stainless Steel Feeder Valve is engineered to meet the demanding requirements of industrial environments. It is meticulously crafted from high-grade stainless steel, guaranteeing exceptional durability and longevity. This ensures that the valve can withstand the harshest operating conditions, including extreme temperatures, chemicals, and corrosive materials. By using this feeder valve, businesses can reduce their maintenance costs and downtime significantly.One of the standout features of the Stainless Steel Feeder Valve is its exceptional precision. Precision is crucial in many industries, and this valve delivers it flawlessly. With state-of-the-art technology and engineering expertise, XYZ Corporation has created a valve that offers unparalleled accuracy in material flow control. Its carefully calibrated design allows for precise adjustment of the material feed rate, enabling businesses to optimize their processes and achieve higher levels of efficiency.The feeder valve also boasts an innovative sealing mechanism, ensuring a tight seal and preventing any leakage. This feature is of utmost importance for industries dealing with hazardous or toxic materials. By preventing leaks, the valve contributes to a safer working environment and helps companies comply with strict regulations governing the handling of such substances.Moreover, the Stainless Steel Feeder Valve is equipped with a user-friendly control system. Its intuitive interface allows operators to easily adjust settings and monitor operational parameters. The valve is designed to seamlessly integrate with existing automation systems, enhancing overall process control and minimizing human error. This increased control and automation not only streamline operations but also lead to improved productivity and product quality.XYZ Corporation understands that every industry has unique requirements and standards. To cater to diverse needs, the Stainless Steel Feeder Valve is available in a range of sizes and configurations. The company offers customization options to ensure the valve precisely fits the application at hand. This versatility makes the valve suitable for a wide array of industries, including chemical processing, food and beverage production, pharmaceutical manufacturing, and many more.In addition to the exceptional product quality, XYZ Corporation excels in providing outstanding customer service and technical support. The company's team of experts is readily available to assist customers in selecting the right valve, addressing any concerns, and offering guidance during installation and maintenance processes. XYZ Corporation's commitment to customer satisfaction has earned it a stellar reputation in the industry.The introduction of the Stainless Steel Feeder Valve by XYZ Corporation marks a major milestone in the world of industrial valves. This groundbreaking product's precision, durability, and innovative features set it apart, making it an ideal choice for businesses striving to optimize their operations. With XYZ Corporation's renowned commitment to customer service, industries can rely on the company to provide quality solutions tailored to their specific needs. Explore the Stainless Steel Feeder Valve today and experience unmatched performance in your industrial processes.

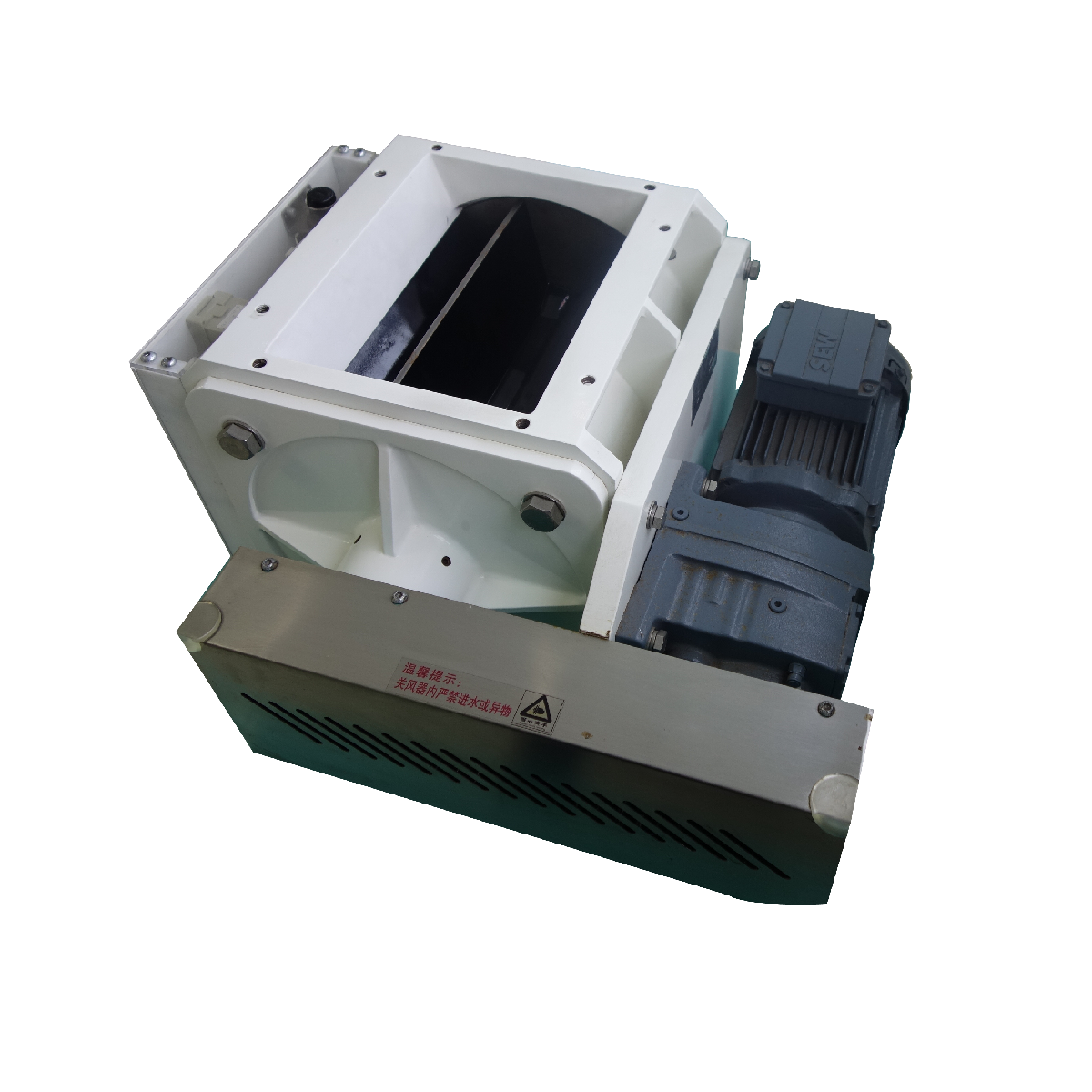

Top-rated Rotary Feeder Factory in the News: Exceptional Quality and Reliability

Title: Leading Rotary Feeder Factory Revolutionizes Industry with Innovative SolutionsIntroduction:In an era of relentless technological advancements, industries across the globe are continuously striving to improve efficiency, accuracy, and productivity. One industry that significantly benefits from innovative solutions is material handling, which relies heavily on machinery such as rotary feeders. In this regard, a prominent rotary feeder factory (name removed) has emerged as a frontrunner in manufacturing cutting-edge rotary feeders that drive the industry forward. With a focus on providing unparalleled quality and reliability, the company has quickly gained recognition as a trusted supplier worldwide.Pioneering Innovations:The rotary feeder factory has achieved acclaim for its consistent drive to innovate. They have successfully combined advanced technology with unparalleled engineering expertise to design rotary feeders that outperform their competitors. By closely collaborating with clients from various industries, the company has gained valuable insights into their unique material handling requirements, allowing them to develop tailored solutions.One of the key innovations the factory has introduced is the incorporation of intelligent control systems into rotary feeders. By integrating modern control technologies, such as PLC and HMI, the factory has enhanced the accuracy and flexibility of its feeders. These intelligent systems enable real-time monitoring, precise control of feed rates, and seamless integration with other material handling equipment, resulting in improved production efficiency.Furthermore, the rotary feeders designed by the factory feature advanced maintenance systems, resulting in reduced downtime and enhanced operational performance. These innovative maintenance initiatives include predictive maintenance algorithms, remote monitoring capabilities, and automated self-diagnostic systems. These features allow for timely identification of potential issues, thus minimizing disruptions and maximizing productivity.Company Overview:With several years of experience and a positive reputation in the industry, the rotary feeder factory has evolved into a globally recognized supplier. Their commitment to delivering exceptional quality and craftsmanship has earned them the trust of clients in various sectors including pharmaceuticals, chemicals, food processing, and mining.The factory conducts rigorous quality control processes at every stage of production to ensure their rotary feeders meet the highest standards. Utilizing state-of-the-art manufacturing facilities and adhering to strict quality management systems, their products undergo comprehensive testing and inspection procedures before reaching the hands of the customers. This stringent approach guarantees optimal performance, reliability, and longevity of the rotary feeders.Moreover, the company boasts a team of highly skilled engineers and technicians dedicated to providing comprehensive technical support and after-sales services. These dedicated professionals are equipped with the knowledge and expertise to promptly address any client queries or concerns, ensuring maximum client satisfaction.Global Reach and Future Prospects:Thanks to its unwavering commitment to innovation and customer satisfaction, the rotary feeder factory has seen remarkable growth and expansion worldwide. Its products have been well-received in various international markets, allowing the company to establish a strong global presence.Looking ahead, the rotary feeder factory envisions continuous growth and market leadership by further diversifying their product portfolio. The company aims to expand its range of rotary feeders to cater to the evolving needs of different industries. Additionally, they plan to increase research and development efforts to stay at the forefront of technology and introduce even more groundbreaking solutions.In conclusion, the rotary feeder factory has truly revolutionized the material handling industry with its pioneering innovations and unwavering commitment to excellence. Through their advanced technology, industry expertise, and unparalleled dedication to customer satisfaction, they continue to set new benchmarks for rotary feeder performance worldwide.

Exploring the Growing Market for Pipe Fittings in the Construction and Real Estate Business Directory

The construction and real estate industry have been on the rise for the past few years. With the increasing demand for residential and commercial buildings, the need for high-quality construction materials is also rising. One such material that is indispensable in the construction industry is metal air pipe fittings.Metal air pipe fittings are plumbing components that are used to connect and join air pipes together. These fittings are made of high-quality metal alloys that are corrosion-resistant and durable. They are designed to withstand high-pressure and temperature conditions in air piping systems. These fittings are widely used in compressed air systems, HVAC systems, and pneumatic systems.Construction and Real Estate Business Directory is a comprehensive directory that provides information about various suppliers, manufacturers, and distributors of pipe fittings. If you are in the construction or real estate industry, you can benefit greatly from using this directory to source for high-quality metal air pipe fittings.Why use Metal Air Pipe Fittings in Construction?There are many reasons why metal air pipe fittings are preferred over other materials in construction. Some of these reasons include:Durability: Metal air pipe fittings are made of high-quality materials that are resistant to wear and tear. They can withstand harsh working conditions and last for a long time without the need for frequent replacements.Corrosion Resistance: Metal air pipe fittings are resistant to corrosion, which makes them an ideal choice for use in humid and wet environments. They are not susceptible to rust and can withstand exposure to water and other environmental factors.High-Pressure and Temperature Resistance: Metal air pipe fittings are designed to withstand high-pressure and temperature conditions in air piping systems. They can handle pressure up to 250 PSI and are suitable for use in high-temperature environments.Easy to Install: Metal air pipe fittings are easy to install and require no special tools or expertise. They can be connected using compression fittings, flanges, or welding.Low Maintenance: Metal air pipe fittings require minimal maintenance and can be easily cleaned using a damp cloth. This makes them a cost-effective solution in the long run.Where to Source for Metal Air Pipe FittingsConstruction and Real Estate Business Directory is a one-stop-shop for all your metal air pipe fittings needs. This directory provides a list of verified suppliers, manufacturers, and distributors of high-quality metal air pipe fittings in your area. You can easily search for the type of fittings you need based on your specifications, and get in touch with the supplier directly.ConclusionMetal air pipe fittings are an essential component in any construction project. They are durable, corrosion-resistant, and can withstand high-pressure and temperature conditions. Using Construction and Real Estate Business Directory, you can easily source for high-quality metal air pipe fittings from verified suppliers, manufacturers, and distributors in your area. This will save you time and money, and ensure that you get the best quality fittings for your construction project.

Major News: Unveiling an Innovative Content Drop Method via Rotary Valve

Title: Industry Leading Valve Manufacturer Introduces Revolutionary Content Drop SolutionIntroduction:In the relentless pursuit of innovation and advancement, renowned valve manufacturer X has recently introduced a groundbreaking technology called the Content Drop through Rotary Valve (CDRV). As a leading player in the industry, X continues to excel in providing state-of-the-art solutions to various sectors. With the introduction of CDRV, the company aims to revolutionize the valve manufacturing process, offering enhanced efficiency, precision, and reliability while catering to the diverse needs of their clients.1. Background of Valve Manufacturing Industry:The valve manufacturing industry plays a crucial role in numerous sectors, including oil and gas, chemical processing, power generation, and water treatment. Valves are essential components that control the flow of fluids and gases, ensuring safe and reliable operations. As technology advances, companies are constantly seeking new solutions to address the challenges posed by demanding applications, fluctuating temperatures, and the need for efficiency.2. Introducing Content Drop through Rotary Valve (CDRV):X's CDRV innovation encompasses a revolutionary approach to valve manufacturing. The new technology allows for the seamless introduction of metered content into the valve chamber, enabling precise control while improving efficiency and reducing downtime. Through the Content Drop mechanism, operators can accurately regulate the flow and properties of the content, ensuring optimal performance and reliability.3. Enhanced Efficiency and Precision:CDRV significantly improves the efficiency and precision of the valve manufacturing process, minimizing wastage, and reducing operational costs for clients. With the Content Drop mechanism, the valves can be customized to meet specific requirements, whether it be controlling fluid flow, pressure, or temperature regulation. The advanced design allows for seamless integration into existing systems, requiring minimal modifications and enhancing productivity.4. Reliability and Safety:Maintaining utmost reliability and safety standards is paramount in the valve manufacturing industry. X's CDRV solution ensures the consistent and precise function of valves, reducing the risk of leaks, downtime, and potentially hazardous situations. By incorporating advanced technology and engineering practices, X provides clients with peace of mind, knowing that their operations are secure and optimized.5. Wide-Spectrum Applications:X's CDRV innovation caters to a wide range of applications across various industries. From the rigor of the oil and gas sector, where valves are subjected to extreme temperatures and pressures, to the sensitive requirements of the pharmaceutical and food industries, valving solutions need to meet stringent criteria. The Content Drop through Rotary Valve system caters to this diverse array of applications, offering unparalleled versatility and adaptability.6. Sustainable Manufacturing Practices:X is committed to sustainable manufacturing processes and environmental responsibility. The CDRV technology aligns with the company's core values by minimizing material wastage and optimizing energy consumption. By reducing the need for extensive maintenance and overhauls, X's CDRV solution ensures extended operational life cycles, resulting in reduced waste generation and a greener footprint.Conclusion:X's introduction of Content Drop through Rotary Valve (CDRV) highlights their ongoing commitment to innovation and industry excellence. This game-changing technology allows for enhanced efficiency, precision, and safety in valve manufacturing, catering to a broad range of applications. With its versatility, reliability, and sustainability focus, X reaffirms its market leadership and continues to drive the valve manufacturing industry towards a more advanced and efficient future.

Efficient and Quick Cleaning Rotary Valve: The Latest Innovation in Cleaning Technology

Fast Cleaning Rotary Valve: A Breakthrough in Material Handling TechnologyIn the ever-evolving world of material handling technology, the demand for efficient and reliable equipment is continuously growing. Manufacturers and processors are constantly seeking solutions that can streamline their operations, improve productivity, and reduce downtime. Addressing this need, a leading player in the industry has introduced an innovative Fast Cleaning Rotary Valve, showcasing their commitment to delivering cutting-edge solutions to their customers.The Fast Cleaning Rotary Valve, developed by [Company Name], has quickly gained attention for its exceptional performance and unique design. This revolutionary valve is specifically engineered to minimize downtime during cleaning and maintenance procedures, making it an ideal choice for applications that require frequent product changes or strict hygiene standards.One of the key features of the Fast Cleaning Rotary Valve is its quick-release capabilities, allowing for swift and easy access to the rotor and housing for cleaning and inspection. This not only reduces the time required for maintenance but also improves overall operational efficiency. Additionally, the valve is designed to ensure thorough cleaning, preventing cross-contamination and maintaining product integrity.The design of the Fast Cleaning Rotary Valve also prioritizes durability and longevity. Constructed from high-quality materials and precision-engineered components, the valve is built to withstand the rigors of heavy-duty applications, delivering reliable performance and minimizing the need for frequent replacements.Furthermore, [Company Name] offers customization options for the Fast Cleaning Rotary Valve to suit specific application requirements. Whether it is the choice of materials, rotor configurations, or additional features, customers have the flexibility to tailor the valve to their exact needs, further enhancing its versatility and effectiveness.Incorporating state-of-the-art technologies and innovative engineering, the Fast Cleaning Rotary Valve exemplifies [Company Name]'s dedication to pushing the boundaries of material handling solutions. With a strong focus on research and development, the company continues to drive advancements in the industry, consistently staying ahead of the curve and setting new standards for performance and reliability.Founded over [X] years ago, [Company Name] has established itself as a trusted and respected name in the field of material handling equipment. With a comprehensive range of products and solutions, the company serves a diverse clientele across various industries, including food processing, pharmaceuticals, chemicals, and more. Known for their commitment to quality, reliability, and customer satisfaction, [Company Name] has built a solid reputation as a leader in the market.The introduction of the Fast Cleaning Rotary Valve is a testament to [Company Name]'s dedication to meeting the evolving needs of their customers, as well as their capacity for innovation and excellence. By addressing the challenges faced by manufacturers and processors in material handling, the company has once again demonstrated its ability to deliver practical and impactful solutions that drive efficiency and productivity.As industries continue to seek ways to optimize their operations and maximize productivity, the Fast Cleaning Rotary Valve stands out as a game-changing innovation that offers tangible benefits. Its ability to streamline maintenance processes, enhance cleanliness, and endure demanding conditions makes it a valuable addition to any material handling setup.In conclusion, the Fast Cleaning Rotary Valve represents a significant advancement in material handling technology, and its introduction underscores [Company Name]'s unwavering commitment to innovation and customer satisfaction. With its exceptional performance, durability, and customization options, the valve is set to make a lasting impact in the industry, setting a new standard for efficiency and reliability in material handling equipment.

Discover the Latest Advancements in Rotary Feeder Technology

Title: High-Performance Rotary Feeder Innovates Material Handling ProcessesIntroduction:In a constant quest for superior material handling solutions, companies across industries rely heavily on innovative technology to enhance productivity and efficiency. One such groundbreaking development is the recently launched Valve Rotary Feeder, designed to revolutionize material handling processes. Developed by a prominent engineering firm, this state-of-the-art rotary feeder seamlessly combines exceptional performance with precision, ensuring seamless material flow and optimal operations.Body:1. Transition to discussing the Valve Rotary Feeder:The Valve Rotary Feeder showcases a range of cutting-edge features that set it apart from conventional material handling systems. Built with the latest advancements in engineering technology, this comprehensive solution has the potential to redefine material handling across various sectors.2. Efficient Material Handling:The Valve Rotary Feeder boasts an unmatched ability to handle bulk materials with the utmost precision. Its high-performance operation drastically reduces issues related to contamination, spillages, and product loss during transfer. This innovative technology ensures continuous, uniform material flow, thus streamlining downstream processes and improving overall productivity.3. Reliable and Durable Construction:Engineered using top-grade materials, the Valve Rotary Feeder exhibits remarkable strength and durability, guaranteeing a long operational life for companies investing in this solution. Its resilient construction also ensures resistance to various abrasive materials and harsh working conditions, making it an ideal choice for industries handling challenging materials.4. Precision Control:With the incorporation of advanced control mechanisms, the Valve Rotary Feeder enables precise material dosing and flow control. This feature facilitates accurate material distribution and ensures optimal usage, significantly reducing waste and associated costs. The feeder's ability to handle a wide range of materials of varying textures and characteristics enhances its adaptability, making it suitable for diverse industry applications.5. Easy Maintenance and Enhanced Safety:Designed with user convenience in mind, the Valve Rotary Feeder offers hassle-free maintenance procedures while adhering to strict safety standards. Its modular design allows for quick and easy repairs or replacements, reducing downtime and maximizing productivity. Furthermore, the incorporation of safety features, such as emergency shut-off mechanisms and enhanced sealing, ensures the well-being of operators and prevents potential accidents.6. Versatile Applications:The Valve Rotary Feeder finds vast applications in numerous sectors, including but not limited to cement, mining, food processing, pharmaceuticals, and chemicals. Its ability to handle various materials, such as powders, granules, pellets, and abrasive substances, makes it an indispensable asset for industries prioritizing seamless material handling with minimal downtime.7. Environmental Considerations:Keeping sustainability in mind, the Valve Rotary Feeder minimizes the risk of emissions and dust, thereby reducing environmental impact. Its efficient material handling and precise control contribute to responsible resource utilization, ensuring companies meet stringent environmental regulations without compromising on operational efficiency.8. Industry Impact and Potential:The introduction of the Valve Rotary Feeder holds significant potential for revolutionizing material handling practices across industries. Its ability to automate processes, optimize efficiency, and minimize product loss positions it as a game-changer in the field of material handling. As a result, companies investing in this advanced solution can yield higher productivity, reduce costs, and gain a competitive edge in the market.Conclusion:In conclusion, the Valve Rotary Feeder represents a breakthrough in material handling technology, offering unparalleled precision, efficiency, and reliability. With its innovative design, the feeder addresses longstanding challenges in material flow, ensuring optimal operational performance across various industries. By investing in this state-of-the-art solution, companies can streamline their processes, increase productivity, and stay at the forefront of a rapidly evolving market.