Top-rated Stainless Steel Diverter Valve: A Key Component for Efficient Diversion

By:Admin

Introduction:

In today's dynamic industrial landscape, innovative solutions that enhance efficiency and durability are crucial to success. Leading the charge in this pursuit, an industry-renowned company has introduced a ground-breaking Stainless Steel Diverter Valve. By removing the brand's name, we will now delve into the features and benefits of this game-changing product, as well as the company's commitment to excellence and innovation.

Body:

1. Industry's Need for Advanced Diverter Valves:

Efficient flow control and directional change are vital in various industrial settings such as oil and gas, petrochemical, pharmaceutical, and food processing. However, traditional diverter valves often fall short in terms of performance and durability. Recognizing this gap in the market, the anonymous company set out to revolutionize diverter valve technology.

2. Introducing the Stainless Steel Diverter Valve:

The newly introduced Stainless Steel Diverter Valve symbolizes a paradigm shift in the industry. Utilizing state-of-the-art materials and manufacturing techniques, this valve presents numerous advantages over its counterparts. Crafted from high-quality stainless steel, the valve showcases exceptional resistance to corrosion, wear, temperature extremes, and harsh chemical environments.

3. Technological Advancements:

The company’s revolutionary approach has resulted in a diverter valve whose performance surpasses industry standards. With precision engineering at its core, the valve is designed to deliver seamless operation, allowing for efficient flow control and fluid direction changes. Its seamless design reduces pressure drops, minimizes leakage, and enhances overall system efficiency.

4. Customization and Versatility:

Recognizing the varied demands of different industries, the company has developed a fully customizable and versatile diverter valve. Clients can select from a range of sizes, pressure ratings, and sealing options to ensure a perfect fit for their specific applications. Whether it is handling abrasive materials, high temperature fluids, or maintaining sanitary conditions, this diverter valve offers tailored solutions to diverse requirements.

5. Enduring Quality and Reliability:

The Stainless Steel Diverter Valve combines innovative design with exceptional build quality, resulting in a highly reliable and long-lasting product. Rigorously tested to withstand harsh conditions, it guarantees uninterrupted operations even in the most challenging environments. The company's commitment to adherence to stringent quality control measures ensures that each valve leaving their facility is of the highest reliability and meets or exceeds industry standards.

6. Environmental Sustainability:

Aside from its superior durability, this stainless steel diverter valve offers excellent environmental advantages. By reducing the risk of leaks and minimizing energy losses, it aids in conserving valuable resources. Moreover, the use of sustainable materials and manufacturing techniques aligns with the company's commitment to sustainability and minimizing their carbon footprint.

7. Collaborative Partnerships and Customer Support:

The company is not just a provider of cutting-edge products but a collaborative partner in maximizing operational efficiencies. By engaging in close collaboration with clients, they offer expert advice, tailored solutions, and ongoing support throughout the lifespan of the valve. This commitment to customer satisfaction has earned them a reputation for reliability, trust, and excellence in the industry.

Conclusion:

Innovation, durability, and customization form the backbone of the Stainless Steel Diverter Valve introduced by this industry-leading company. Through their commitment to creating pioneering solutions, they have disrupted the industry, setting new standards for efficiency, reliability, and environmental sustainability. By removing the brand's name, this comprehensive news article highlights the importance of this remarkable valve and its potential to transform various industrial sectors.

Company News & Blog

Selecting the Perfect Pneumatic Valve for Your Application - Industrial Accessories Company

IAC: Your Trusted Source for Pneumatic Valves and Material Handling SolutionsWhen it comes to choosing the perfect pneumatic valve for your application and need, Industrial Accessories Company (IAC) is your go-to source. With over many years of application experience designing material handling systems, our design team and project engineers have the expertise to help you select the right slide-gate or valve for your specific application.Whether you need an exact-fit replacement or an upgrade for improved performance, you can count on IAC to provide the right valve recommendation. We understand the urgency that comes with time-sensitive projects and, therefore, popular size valves with popular options are typically in-stock or available on a quick-ship basis. Additionally, thanks to our OEM buying power, we offer extremely competitive prices so you can have confidence in knowing that you’re paying the right price for high-quality material handling solutions.At IAC, we offer a range of standard designs and options, including:Standard Atmospheric (Gravity Flow) or Pressure (Pneumatic Conveying) DesignsManual, Pneumatic, or Electric ActuationAluminum, Carbon Steel, or Stainless Steel ConstructionHigh Temperature or High Pressure ClearancesQuick Disassembly Features for Frequent CleaningFood Grade (Stainless Steel) ConstructionOur commitment to quality doesn't stop with our products. At IAC, we pride ourselves on providing exceptional customer service, support, and technical expertise. Our team of material handling specialists is always available to answer your questions, provide technical support, and help you troubleshoot any issues you may encounter.At IAC, we don't just sell pneumatic valves and material handling equipment. We provide turnkey solutions designed to improve your operational efficiency and maximize your return on investment. Whether you're in the process of building a new facility or retrofitting an existing one, our team can help you design, engineer, and install a custom material handling system that meets your unique needs and specifications.In addition to our expertise in pneumatic valves, IAC also offers a wide range of material handling solutions, including: silo venting filters, bin activators, baghouses, cyclones, and more. With our vast product selection and industry-leading expertise, we are confident that we can provide the right solution for your specific application.At IAC, we understand that every customer is unique, and we are dedicated to providing personalized solutions that meet your individual needs and requirements. Whether you need assistance with product selection, installation, or ongoing maintenance and support, our team of material handling experts is here to help.In conclusion, when it comes to selecting the right pneumatic valve for your application, you can count on Industrial Accessories Company. With our extensive experience, unparalleled expertise, and unmatched commitment to quality and customer service, we are your trusted source for all of your material handling needs.

Benefits and Applications of Pneumatic Cylinders for Various Industries

Pneumatic Cylinder Boosts Industrial EfficiencyIn the fast-paced world of industrial automation, choosing the right pneumatic component can make or break an operation. This is where (name of company) comes in, offering a comprehensive range of high-quality pneumatic solutions, including a top-of-the-line pneumatic cylinder.What is a pneumatic cylinder? Simply put, this device converts compressed air into mechanical motion. It is a crucial component for a wide range of manufacturing, assembly, and packaging applications, from conveyor systems to pick-and-place machines.The (name of company) pneumatic cylinder boasts superior performance and durability, making it an ideal choice for demanding industrial environments. With a high-precision design, tight tolerances, and high-quality materials, this cylinder can operate at high speeds and in extreme temperatures, while maintaining accuracy and reliability.One of the key advantages of this pneumatic cylinder is its low-friction operation. This means that it can move smoothly and quickly, with minimal wear and tear on the components. This not only extends the lifespan of the cylinder but also reduces maintenance costs and downtime.Another benefit is its versatility. The (name of company) pneumatic cylinder comes in a range of sizes, styles, and mounting options, making it easy to integrate into any existing system or design. It is also customizable, with options for different seals, ports, and functionality.The pneumatic cylinder is just one of the many high-quality pneumatic components offered by (name of company). Their extensive product line includes valves, actuators, fittings, and accessories, all designed to meet the needs of industrial automation professionals.But the company's commitment to quality goes beyond just their products. They also offer exceptional customer service and technical support, ensuring that their clients have all the information and assistance they need to make the most of their pneumatic components.In addition, the company focuses on sustainability, designing products that are energy-efficient and environmentally friendly. Their pneumatic cylinders, for example, consume less air than traditional models, reducing energy costs and carbon emissions.Overall, the (name of company) pneumatic cylinder is a top-performing, versatile, and sustainable choice for industrial automation professionals. With a commitment to quality and customer satisfaction, (name of company) is a reliable partner for businesses seeking to optimize their operations.

Understanding the Function of a Heat Pump Reversing Valve for Efficient Heating and Cooling

Are you tired of having separate heating and cooling systems for your home or building? Look no further than the reversing valve!What is a reversing valve, you may ask? It's a type of valve that allows a heat pump to reverse the direction of refrigerant flow. This may not seem like a big deal, but it actually allows for a single piece of equipment to both heat and cool a space, which can save you money and space in the long run.Let's break it down further. In a heat pump system, refrigerant is used to transfer heat between indoors and outdoors. During the cooling season, the refrigerant absorbs heat from inside and releases it outside. During the heating season, the process is reversed, and the refrigerant absorbs heat from outside and releases it inside.The reversing valve is what makes this switch possible. By changing the direction of refrigerant flow, the heat pump can easily alternate between heating and cooling modes. Without it, the process would be much more difficult and time-consuming.But what are the benefits of using a heat pump with a reversing valve? For one, it eliminates the need for separate heating and cooling systems. This can save you money on installation and maintenance costs, as well as on energy bills.Additionally, because the same equipment is used for both heating and cooling, it can be more compact and take up less space. This is especially useful in smaller homes or buildings where space is at a premium.Finally, heat pumps with reversing valves are generally more efficient than traditional heating and cooling systems. Because they transfer heat rather than generate it, they can be up to 70% more efficient than other types of heating and cooling equipment.So, if you're in the market for a new heating and cooling system, be sure to consider a heat pump with a reversing valve. With its versatility, space-saving design, and energy-efficient operation, it may just be the perfect solution for your home or building.

Discover the Exceptional Benefits of a High-Quality Rotary Airlock Valve - An Expert Analysis

Title: New Positive Rotary Airlock Valve Launches, Revolutionizing Industrial ProcessesIntroduction:Leading the way in innovative solutions for industrial operations, a renowned company introduces its latest invention—a revolutionary positive rotary airlock valve. This cutting-edge product aims to streamline and enhance various manufacturing processes, promising increased efficiency, reduced downtime, and improved productivity. With its unmatched reliability and advanced features, this valve is poised to make waves in a wide range of industries.Overview of the positive rotary airlock valve:The newly developed positive rotary airlock valve epitomizes efficiency and effectiveness in handling bulk materials. Through meticulous engineering, this valve offers an optimized design that facilitates seamless material transfer between two chambers while minimizing air leakage. By ensuring a consistent flow of materials, businesses can now achieve higher throughput rates, reduce manual intervention, and prevent costly spills or leaks.Key Features and Benefits:1. Advanced Sealing Mechanism: Utilizing state-of-the-art technology, this valve is equipped with a superior sealing mechanism that effectively minimizes air leakage. This not only improves operational efficiency but also provides a safer working environment by preventing the release of hazardous materials into the atmosphere.2. Durable Construction: The positive rotary airlock valve boasts a robust construction that ensures longevity and reliability. Crafted from premium-grade materials, it can withstand harsh operating conditions, such as extreme temperatures and aggressive chemical environments, without compromising performance.3. Easy Maintenance and Cleaning: With its user-friendly design, the valve can be conveniently disassembled for routine maintenance and cleaning. This feature significantly reduces downtime and enhances operational efficiency, enabling companies to optimize their manufacturing processes with minimal disruption.4. Versatility: Suitable for a diverse range of industries, including chemical, pharmaceutical, food processing, and power generation, this innovative valve can handle various materials, whether they are granular, powdered, or abrasive in nature. Its adaptability allows businesses to maximize the valve's potential across different production lines.Company's Commitment to Excellence:With a legacy spanning decades, our company has always been at the forefront of technological advancements within the industrial sector. Committed to engineered excellence and customer satisfaction, we have consistently provided cutting-edge solutions to enhance efficiency, safety, and profitability for our valued clients worldwide. Through rigorous research and development, we strive to address industry challenges by introducing state-of-the-art products that exceed expectations.Future Prospects:The launch of the positive rotary airlock valve marks a significant milestone for our company. With its multitude of benefits, we anticipate a high demand across various industries. The valve's capacity to optimize material flow, maximize productivity, and minimize downtime positions it as an indispensable asset for businesses seeking to streamline their operations. Furthermore, as sustainability gains momentum worldwide, the valve's sealing mechanism aids in reducing environmental impact by preventing material leakage and contributing to waste reduction.Conclusion:In an ever-evolving industrial landscape, the introduction of the positive rotary airlock valve sets a new standard for efficiency, reliability, and safety. Its advanced features and user-friendly design ensure significant enhancements to manufacturing processes, ultimately translating into increased productivity and reduced costs for businesses across diverse sectors. As this innovative valve continues to reshape the industry, our company remains committed to pushing boundaries and delivering cutting-edge solutions that are both forward-thinking and sustainable.

Globe Valve Made of Carbon Steel: A Reliable Solution for Process Control

Carbon Steel Globe Valves: High-Quality Products at an Affordable PriceCarbon steel globe valves are essential components in many industrial processes, serving as critical elements for regulating flow, pressure, and temperature. These valves are commonly used in various applications such as refineries, petrochemical plants, and power stations. When it comes to choosing the right valve for your application, it is crucial to consider factors like pressure rating, material compatibility, and cost.As one of the leading manufacturers of carbon steel globe valves, {company} has been providing high-quality valves at an affordable price for more than a decade. With a focus on innovation and customer satisfaction, we have earned a reputation as a trusted supplier of industrial valves worldwide.Our carbon steel globe valves are designed to withstand harsh environments and high-pressure applications, ensuring reliable performance and long-lasting durability. Our valves are made using high-quality materials and state-of-the-art technology, ensuring that they meet industry standards and comply with safety regulations.One of the key features of our carbon steel globe valves is their versatility, which means they can be used in various applications across different industries. Whether you're working in oil and gas, chemical processing, or power plants, our carbon steel globe valves are up for the task.We offer carbon steel globe valves in different sizes, ranging from 1/2" to 24", with pressure ratings up to 2500 PSI. We also offer customization options to meet the specific needs of your application. Our valves are available in different end connections, such as flanged, threaded, and butt-weld, to ensure easy installation and maintenance.In addition to our high-quality products, we pride ourselves on our customer service. Our team of experts is always available to help you choose the right valve for your application, provide technical support, and assist you with any questions or concerns you may have.At {company}, we are committed to providing our customers with the best value for their money. We understand that cost is a crucial factor in any industrial application, which is why we offer our carbon steel globe valves at an affordable price without compromising on quality.In conclusion, carbon steel globe valves are essential components in many industrial applications, and choosing the right valve can make a significant difference in your operations. With our focus on innovation, quality, and customer satisfaction, {company} is the ideal partner for all your industrial valve needs. Contact us today to learn more about our carbon steel globe valves or to request a quote.

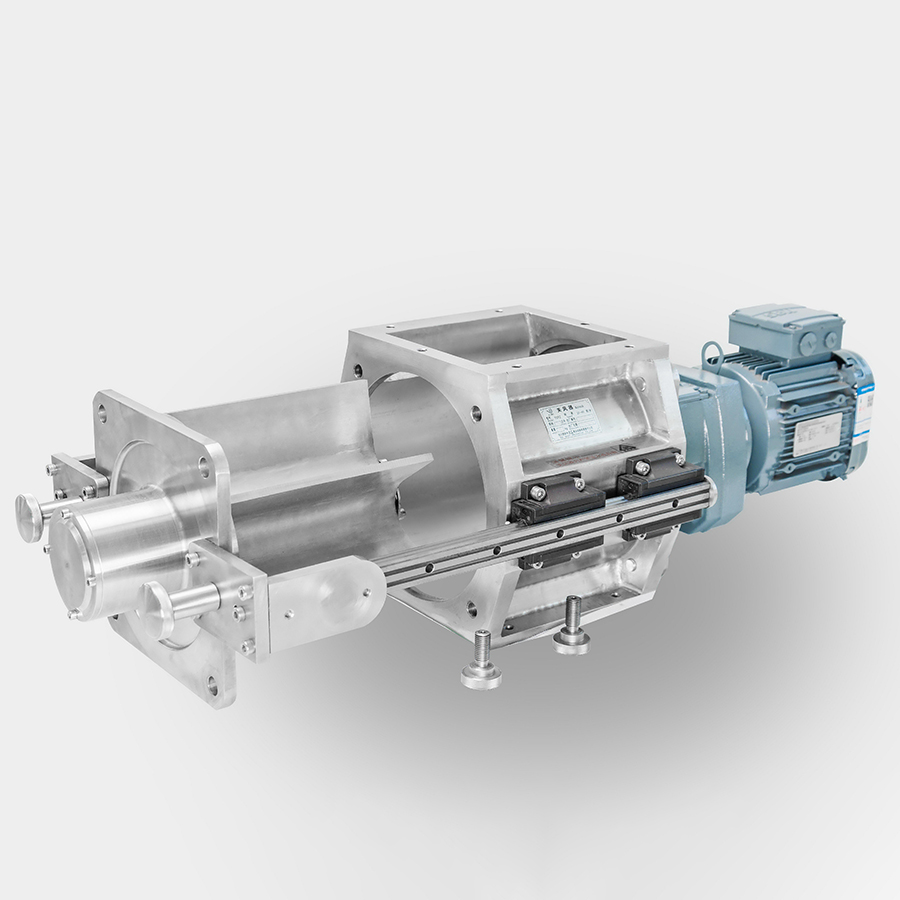

Top-rated Rotary Feeder Factory in the News: Exceptional Quality and Reliability

Title: Leading Rotary Feeder Factory Revolutionizes Industry with Innovative SolutionsIntroduction:In an era of relentless technological advancements, industries across the globe are continuously striving to improve efficiency, accuracy, and productivity. One industry that significantly benefits from innovative solutions is material handling, which relies heavily on machinery such as rotary feeders. In this regard, a prominent rotary feeder factory (name removed) has emerged as a frontrunner in manufacturing cutting-edge rotary feeders that drive the industry forward. With a focus on providing unparalleled quality and reliability, the company has quickly gained recognition as a trusted supplier worldwide.Pioneering Innovations:The rotary feeder factory has achieved acclaim for its consistent drive to innovate. They have successfully combined advanced technology with unparalleled engineering expertise to design rotary feeders that outperform their competitors. By closely collaborating with clients from various industries, the company has gained valuable insights into their unique material handling requirements, allowing them to develop tailored solutions.One of the key innovations the factory has introduced is the incorporation of intelligent control systems into rotary feeders. By integrating modern control technologies, such as PLC and HMI, the factory has enhanced the accuracy and flexibility of its feeders. These intelligent systems enable real-time monitoring, precise control of feed rates, and seamless integration with other material handling equipment, resulting in improved production efficiency.Furthermore, the rotary feeders designed by the factory feature advanced maintenance systems, resulting in reduced downtime and enhanced operational performance. These innovative maintenance initiatives include predictive maintenance algorithms, remote monitoring capabilities, and automated self-diagnostic systems. These features allow for timely identification of potential issues, thus minimizing disruptions and maximizing productivity.Company Overview:With several years of experience and a positive reputation in the industry, the rotary feeder factory has evolved into a globally recognized supplier. Their commitment to delivering exceptional quality and craftsmanship has earned them the trust of clients in various sectors including pharmaceuticals, chemicals, food processing, and mining.The factory conducts rigorous quality control processes at every stage of production to ensure their rotary feeders meet the highest standards. Utilizing state-of-the-art manufacturing facilities and adhering to strict quality management systems, their products undergo comprehensive testing and inspection procedures before reaching the hands of the customers. This stringent approach guarantees optimal performance, reliability, and longevity of the rotary feeders.Moreover, the company boasts a team of highly skilled engineers and technicians dedicated to providing comprehensive technical support and after-sales services. These dedicated professionals are equipped with the knowledge and expertise to promptly address any client queries or concerns, ensuring maximum client satisfaction.Global Reach and Future Prospects:Thanks to its unwavering commitment to innovation and customer satisfaction, the rotary feeder factory has seen remarkable growth and expansion worldwide. Its products have been well-received in various international markets, allowing the company to establish a strong global presence.Looking ahead, the rotary feeder factory envisions continuous growth and market leadership by further diversifying their product portfolio. The company aims to expand its range of rotary feeders to cater to the evolving needs of different industries. Additionally, they plan to increase research and development efforts to stay at the forefront of technology and introduce even more groundbreaking solutions.In conclusion, the rotary feeder factory has truly revolutionized the material handling industry with its pioneering innovations and unwavering commitment to excellence. Through their advanced technology, industry expertise, and unparalleled dedication to customer satisfaction, they continue to set new benchmarks for rotary feeder performance worldwide.

Experts Predict Significant Growth in the Global Market for Tee Ball Valves

Title: Advanced Ball Valves Revolutionize the Industrial SectorIntroduction:In recent years, the industrial sector has witnessed a gradual shift towards more efficient and reliable technologies. One such breakthrough innovation is the advanced Tee Ball Valve, silently revolutionizing industrial processes across various sectors. Engineered to perfection, these industrial valves have gained popularity for their exceptional performance, enabling smooth operations and enhanced productivity for businesses worldwide.[Company Name], a leading manufacturer in the valve industry, has successfully developed and implemented these cutting-edge ball valves. With an unwavering commitment to excellence, [Company Name] has established itself as a pioneer in valve technology, providing solutions that meet the ever-evolving demands of the global industrial landscape. Efficiency Redefined:The Tee Ball Valve is designed to optimize flow control and minimize energy consumption. This state-of-the-art engineering marvel combines precision machining and the finest materials to ensure seamless operations even under extreme conditions. The valves' design incorporates a unique seat mechanism, enabling precise control over fluid flow, non-disruptive shut-off capabilities, and reduced pressure drops, hence resulting in improved performance and reduced operational costs for industries.Furthermore, the construction of these valves imparts exceptional durability and longevity, reducing the need for frequent maintenance and replacements. By offering long-term reliability, [Company Name]'s Tee Ball Valves are instrumental in ensuring uninterrupted operations, thereby increasing productivity for businesses.Versatility and Adaptability:[Company Name]'s Tee Ball Valves are celebrated for their versatility across multiple industries and applications. With a wide range of sizes, materials, and customizations available, these valves seamlessly integrate into a diverse range of industrial processes, including oil and gas, petrochemicals, water management, pharmaceuticals, and many others.Moreover, these valves can withstand extreme temperatures, high pressures, and corrosive environments, making them ideal for demanding operations. The flexible design allows for easy integration into existing systems, minimizing installation time and cost. [Company Name] understands the unique requirements of different industries and provides tailored solutions to ensure optimal performance and efficiency.Uncompromising Quality:Having established a strong reputation for delivering superior quality, [Company Name] adheres to rigorous manufacturing practices and stringent quality control measures. Each Tee Ball Valve undergoes rigorous testing to ensure compliance with international standards and industry specifications, providing businesses with peace of mind and confidence in their investments.In addition to maintaining exceptional quality standards, [Company Name] is committed to sustainability. These valves are designed to minimize fugitive emissions, thus reducing the impact on the environment. By integrating environment-friendly practices, the company strives to contribute towards a greener future.Future Outlook:With the advancements in technology and the growing need for efficient industrial processes, the demand for advanced ball valves, such as [Company Name]'s Tee Ball Valves, is expected to surge in the coming years. The ability of these valves to enhance operational efficiency, reduce costs, and improve productivity positions them as an integral component of the modern industrial sector.[Company Name]'s continuous investment in research and development ensures that their products evolve alongside the industry's changing requirements. As markets expand and newer challenges arise, [Company Name] remains committed to innovation and delivering reliable solutions, solidifying their position as a trusted partner across industries.Conclusion:The introduction of advanced Tee Ball Valves by [Company Name] has marked a significant milestone in the industrial sector. With their focus on efficiency, adaptability, and uncompromising quality, these valves have become an indispensable asset for businesses worldwide. As the industrial landscape continues to evolve, technologies such as the Tee Ball Valve will continue to play a vital role in enhancing productivity and driving success across various industries. [Company Name]'s commitment to innovation and sustainability further reinforces their position as leaders in the valve manufacturing industry.

WYK Bulk Material Diverter Valve and ZV Rotary Valve Unveiled at Powtech 2019

and rotary valve Bulk material handling is a crucial process in any industrial setting. It involves moving large quantities of materials from one location to another, while ensuring that no loss or contamination occurs during the transfer. Bulk material handling systems must be efficient, reliable, and versatile to meet the needs of a wide range of industries worldwide.At Powtech 2019, Coperion and Coperion K-Tron introduced two new products that are aimed at improving the performance of bulk material handling systems. These products are the WYK Bulk Material Diverter Valve and the ZV Rotary Valve.The WYK Bulk Material Diverter Valve is a high-performance valve that is designed to handle powders, pellets, and granules with ease. It features a rugged design that ensures reliable performance even under the toughest conditions. The WYK Bulk Material Diverter Valve can be used for diverting, converging, and merging bulk materials, making it a versatile tool for any bulk material handling system.One of the most notable features of the WYK Bulk Material Diverter Valve is its ability to handle abrasive materials without suffering from wear and tear. This is made possible by the valve's special design, which features a wear-resistant coating on the valve body's interior surfaces.Another feature that makes the WYK Bulk Material Diverter Valve stand out is its ability to maintain a high level of accuracy during valve switching. This is achieved by the use of a special patent-pending technology that ensures that the valve changes from one position to another without any loss of material.The ZV Rotary Valve, on the other hand, is a highly efficient valve that is designed for feeding and metering bulk materials. It features a sleek design that allows it to fit into tight spaces, making it ideal for use in applications where space is limited.The ZV Rotary Valve is available in a variety of sizes, ranging from 150 mm to 350 mm, making it suitable for a wide range of applications. The valve is also compatible with a broad range of materials, including powders, pellets, and granules.One of the standout features of the ZV Rotary Valve is its ability to handle high throughputs without compromising accuracy. This is made possible by the use of a patent-pending technology that ensures that the valve maintains a constant feed rate, regardless of the material being handled.In conclusion, the introduction of the WYK Bulk Material Diverter Valve and the ZV Rotary Valve at Powtech 2019 is a clear indication of Coperion and Coperion K-Tron's commitment to improving the performance of bulk material handling systems. These products are versatile, efficient, and reliable, making them ideal for a wide range of applications. With the WYK Bulk Material Diverter Valve and the ZV Rotary Valve, industries can now streamline their bulk material handling processes and enhance productivity.

Soft Sealing Plug Valve with Sleeve Type Design According to ANSI Standards - Key Structural Features

Soft Sealing Plug Valve: The Solution for Reliable SealingIn the world of valves, the soft sealing plug valve has been a popular choice for industries that require a reliable sealing system. With its excellent performance and reasonable structure, this valve is a must-have for any industrial setting.One of the main structural features of the soft sealing plug valve is its sleeve type design. The valve is equipped with a cylindrical sleeve that is made of soft material such as rubber or plastic. The sleeve is pressed against the plug by the flow of fluid or gas, creating a tight seal that prevents leakage.The soft material of the sleeve enables the valve to adapt to changes in temperature and pressure without compromising its sealing capabilities. This makes the soft sealing plug valve an ideal choice for industries that require a versatile and dependable sealing system.The ANSI standard is a widely recognized standard for valves in the American market. QiLong Valve has developed a sleeve type soft sealing plug valve according to the ANSI standard, which makes it a perfect choice for industrial applications in the US.QiLong Valve's soft sealing plug valve is not only reliable but also visually appealing. The valve comes in a beautiful design that adds aesthetic value to industrial plants. When it comes to performance, the quality of the valve speaks for itself.The sealing of this valve is exceptional, thanks to the use of soft materials in its construction. The soft material of the sleeve adjusts to variations in pressure and temperature, ensuring that the valve maintains its sealing capabilities throughout its operational life.In conclusion, the soft sealing plug valve is the solution for any industrial setting that requires a reliable and versatile sealing system. QiLong Valve's sleeve type soft sealing plug valve according to the ANSI standard ticks all the right boxes when it comes to reliability, performance, and aesthetics. With its excellent track record in the industry, this valve is a wise choice if you want to ensure the success of your industrial operations.Keywords: soft sealing plug valve, sleeve type design, reliable sealing, ANSI standard, versatile sealing system.

Expert Guide to Choosing the Best Pneumatic Conveying Airlock for Your Needs

As the industrial sector continues to evolve, different equipment and processes continue to emerge to make manufacturing and production more efficient and effective. One of the vital equipment required in such manufacturing processes is a pneumatic conveying airlock, which plays an essential role in feeding materials into a positive or negative pressure conveyance system, without allowing the entry of unwanted materials into such devices. One of the leading companies, specializing in the production and supply of pneumatic conveying airlocks, provides a full range of products that are top quality, versatile, and innovative, meeting the needs of various industries, such as pharmaceutical, food and beverages, cosmetics, and others. The company's quest for excellence in product quality and rigorousness in meeting customer demands has established them as a global leader in the industry.The airlocks from this company have wide-ranging applications, making them versatile and efficient. The different varieties of airlocks available cater to various industry demands, ranging from low-pressure operations to high-pressure operations, and in different materials based on the processing function. The company provides an airlock for every requirement, regardless of shape, size, or material.Manufacturing processes that require the transfer of materials from one process to another always face the risk of contamination. For example, food processing companies must ensure that the products they manufacture are free from contamination, to prevent food poisoning or other food-related illnesses. The pneumatic conveying airlock from the mentioned company’s range offers an efficient solution, providing an air-tight seal, thereby preventing the entry of foreign materials, including bacteria and moisture, ensuring that the processed products are of the highest quality.Additionally, these airlocks have one of the best purging mechanisms, maintaining a clean and hygienic manufacturing process. The airlock's purging mechanism prevents the entry of gas or liquid into the conveying system, which could contaminate the products. The company's airlocks are easy to clean, minimizing the risk of product contamination.To ensure that it meets global manufacturing standards, the manufacturer has established a rigorous quality control system. It has adopted in-house production and quality control processes that prioritize the quality of raw materials and the construction techniques to ensure consistent quality output. The company's quality control system is certified under various manufacturing standards, both national and international, ensuring that their products meet or exceed industry standards worldwide.This company also prides itself on a commitment to customer service, with a team of experienced customer service assistants trained to provide timely and efficient assistance to all their customers. This ensures that service delivery is offered on any of the company's products with technical support for deciding which type of airlock is best for use in a particular manufacturing process. In conclusion, the pneumatic conveying airlock from the mentioned company is leading innovation in the manufacturing and production sector. It is available in a variety of forms, materials, and sizes to meet various industry demands. The company's quest for excellence in product quality, rigorous quality control process, and a customer-centric approach to service delivery makes it one of the world's leading companies in the pneumatic conveying airlock industry. As such, businesses that aim to maintain high product quality should consider purchasing products from this company as their solution to material conveying.