End Discharge Formula (Granules, Packets) - Natural TCM Solution for Digestive Issues

TCMzone dimensions have recently introduced a new product, the Wan Dai Tang End Discharge Formula in granules or packets. This product is now available for purchase online and can be shipped within the continental U.S.Orders received before 3 p.m. MST will be shipped out the same day by UPS or USPS. In addition, orders over $200 will be shipped free of charge within the continental U.S. This offer is an added advantage to customers who are willing to purchase more of this product.However, it is to be noted that the returns or exchange of unopened products will be accepted only when it is returned within a period of 30 days from the date of purchase. A restocking fee of 20% will be applied on all returned items. No returns will be accepted after 30 days, and customers must call for a return authorization and include a copy of the invoice for fully credited returns.TCMzone dimensions take great care in filling, checking, and packaging your order. However, on rare occasions, a package may be damaged or lost in transit. If you receive a package that has been damaged, please save the original box or bottle and all its contents and call the customer service immediately for assistance. If you feel your package may have been lost in transit, contact the customer service immediately for tracking assistance.This product is designed to regulate a woman's period, manage period-related symptoms, and reduce heavy bleeding. This formula is made using traditional Chinese herbs that have proven to be effective over centuries. The product can help restore the balance of hormones in the body, promoting better overall health.One of the related products of TCMzone dimensions that can complement the Wan Dai Tang End Discharge Formula is the Women's Vitality Formula. This product is composed of several herbs that can help nourish the body, manage stress and promote better mental health. It also helps ease menstrual-related discomfort and supports overall reproductive health.TCMzone dimensions are committed to providing their customers with high-quality traditional Chinese medicine products that are backed by scientific research. Their products are safe and effective and have no side effects. They remain the go-to option for those interested in natural and holistic health care. In conclusion, Wan Dai Tang End Discharge Formula by TCMzone dimensions is a new product available, delivering effective results to women users suffering from menstruation-related issues. This reputed brand has been delivering health care products for a while and their Women's Vitality Formula is a product that supplements End Discharge Formula, leading to better energy-promoting, better reproductive health.

Read More

Exploring the Growing Market for Pipe Fittings in the Construction and Real Estate Business Directory

The construction and real estate industry have been on the rise for the past few years. With the increasing demand for residential and commercial buildings, the need for high-quality construction materials is also rising. One such material that is indispensable in the construction industry is metal air pipe fittings.Metal air pipe fittings are plumbing components that are used to connect and join air pipes together. These fittings are made of high-quality metal alloys that are corrosion-resistant and durable. They are designed to withstand high-pressure and temperature conditions in air piping systems. These fittings are widely used in compressed air systems, HVAC systems, and pneumatic systems.Construction and Real Estate Business Directory is a comprehensive directory that provides information about various suppliers, manufacturers, and distributors of pipe fittings. If you are in the construction or real estate industry, you can benefit greatly from using this directory to source for high-quality metal air pipe fittings.Why use Metal Air Pipe Fittings in Construction?There are many reasons why metal air pipe fittings are preferred over other materials in construction. Some of these reasons include:Durability: Metal air pipe fittings are made of high-quality materials that are resistant to wear and tear. They can withstand harsh working conditions and last for a long time without the need for frequent replacements.Corrosion Resistance: Metal air pipe fittings are resistant to corrosion, which makes them an ideal choice for use in humid and wet environments. They are not susceptible to rust and can withstand exposure to water and other environmental factors.High-Pressure and Temperature Resistance: Metal air pipe fittings are designed to withstand high-pressure and temperature conditions in air piping systems. They can handle pressure up to 250 PSI and are suitable for use in high-temperature environments.Easy to Install: Metal air pipe fittings are easy to install and require no special tools or expertise. They can be connected using compression fittings, flanges, or welding.Low Maintenance: Metal air pipe fittings require minimal maintenance and can be easily cleaned using a damp cloth. This makes them a cost-effective solution in the long run.Where to Source for Metal Air Pipe FittingsConstruction and Real Estate Business Directory is a one-stop-shop for all your metal air pipe fittings needs. This directory provides a list of verified suppliers, manufacturers, and distributors of high-quality metal air pipe fittings in your area. You can easily search for the type of fittings you need based on your specifications, and get in touch with the supplier directly.ConclusionMetal air pipe fittings are an essential component in any construction project. They are durable, corrosion-resistant, and can withstand high-pressure and temperature conditions. Using Construction and Real Estate Business Directory, you can easily source for high-quality metal air pipe fittings from verified suppliers, manufacturers, and distributors in your area. This will save you time and money, and ensure that you get the best quality fittings for your construction project.

Read More

Latest Developments in Food Machinery Industry in China

China's Thriving Food Machinery Industry Continues to GrowChina's food machinery industry has experienced rapid growth in recent years, aiding the country's booming food processing and packaging sector. The industry has made significant contributions to increasing food safety, improving manufacturing efficiency, and promoting technological advancements. One of the prominent players in this space is a leading Chinese food machinery company (brand name removed), renowned for its innovative solutions that have transformed the food processing industry.Established in (year), the company has emerged as a trusted and reliable provider of food machinery and equipment. With headquarters located in (city), this esteemed organization has achieved remarkable success by combining cutting-edge technologies with a commitment to producing high-quality products. As a result, the company has gained a solid reputation both domestically and internationally.The ever-evolving food machinery industry has witnessed several major trends, and (brand name removed) has played a crucial role in driving these advancements. The company offers an extensive range of products that cater to various food processing requirements, including meat processing, dairy processing, fruit and vegetable processing, bakery and confectionery, and packaging machinery.One of the key strengths of (brand name removed) lies in its continuous research and development activities. They have a dedicated team of experts who relentlessly work towards developing and enhancing their product offerings. By understanding the unique needs of their customers, they have been able to introduce innovative machinery that improves production efficiency, reduces energy consumption, and ensures food safety.The company's commitment to quality is reflected in its state-of-the-art manufacturing facilities. Equipped with advanced technology and modern infrastructure, (brand name removed) follows strict quality control measures at every stage of production. Their products undergo rigorous testing to ensure compliance with international standards.In addition to catering to the domestic market, (brand name removed) has successfully expanded its reach globally, exporting their products to various countries. They have established strategic partnerships with international distributors and continually participate in major exhibitions and trade fairs, showcasing their diverse product range.Recently, (brand name removed) launched two groundbreaking products that have garnered significant attention within the industry. The first is an automated meat processing machine that revolutionizes the way meat is handled. This machine streamlines the process, improving efficiency and reducing the risk of contamination. It has received accolades for its ability to improve food safety standards.The second product is an advanced packaging machine that offers increased flexibility and precision. This machine is designed to minimize wastage and optimize packaging of food products, ensuring longer shelf life and improved product presentation. (Brand name removed)'s commitment to producing cutting-edge machinery has made them a preferred choice for food processing companies worldwide.Apart from their technological innovations, (brand name removed) also excels in providing exceptional customer service. Their dedicated support team is always available to assist customers with installation, maintenance, and troubleshooting, ensuring seamless operations and minimal downtime.As Chinese food processing and packaging continue to expand, companies like (brand name removed) play a pivotal role in supporting this growth. With their unwavering commitment to innovation, quality, and customer satisfaction, they are poised to maintain their dominance in the food machinery industry.In conclusion, China's food machinery industry has witnessed tremendous growth, thanks to companies like (brand name removed) that lead the way with their innovative and high-quality products. Their dedication to research and development, commitment to quality, and exceptional customer service make them a force to be reckoned with in the global food processing and packaging sector.

Read More

Plastic Valve Solutions for Industrial Needs: Experts in Valves, Global Partnerships, Fast Turnaround

Read More

How to Prepare for Black Friday Sales in 2021

Pre-feeder Proves to Change the Packaging Industry with Automated EfficiencyThe packaging industry is one of the fastest-growing industries globally. The demand for packaged goods has increased due to the rise in e-commerce and the need to protect products during transport. However, the packaging industry is facing several challenges, including the need to increase production efficiency, reduce production costs, and decrease material waste. These challenges have led many companies to explore the adoption of automated systems, one of which the Pre-feeder.With automated technology, the Pre-feeder Proves to Change the Packaging Industry with Automated Efficiency. This machine is a game changer for the packaging industry, and it is helping companies achieve their production goals while mitigating risks. A pre-feeder is an automated system that helps feed and orientate various types of packaging materials, including cartons, pouches, and bags.The Pre-feeder helps in achieving a more efficient and safer packaging process by automating the material feeding process. Material feeding is essential in the manufacturing process, and it consumes a significant portion of the production time. This machine enhances speed and accuracy, freeing up time for other tasks and reducing the likelihood of employees experiencing accidents.This new technology has several benefits. It cuts down on labor costs since it requires only a few employees to operate, reducing the risk of injuries for workers. It leads to a significant reduction in material waste, ensuring that companies can enjoy a more sustainable approach to packaging production. The Pre-feeder can handle larger quantities of packages at a time, improving the overall efficiency of the manufacturing process and shortening production times.Conventional material feeding processes require time and significant manual intervention, which can lead to errors and cost overruns. The Pre-feeder technology ensures that the entire feeding process is automated, thereby reducing the potential for mistakes. This technology's accuracy can contribute to savings in time, materials, and production costs compared to the traditional methods.Pre-feeder manufacturers have placed significant emphasis on safety, and as such, the machine operates with minimal noise and vibration. Also, the closed system eliminates safety hazards that may arise from exposure to nip points and other parts of the machine. The machine is simple to operate, meaning that anyone can run it with minimal training.The Pre-feeder machine's versatility allows it to work with different types of packaging materials, opening up opportunities for companies in diverse industries. The system is compatible with different types of packaging formats, including cartons, pouches, and bags.Lack of proper feeding systems can lead to material jams, which can significantly compromise production. But the Pre-feeder machine has an in-built system for handling material jams, reducing production downtime significantly. This automated feature ensures that production times are uniformly distributed, making the manufacturing process more efficient.The Pre-feeder machine's automated features promote sustainability by reducing the amount of waste generated during the production process. Since it is more accurate than conventional feeding methods, it can reduce the amount of materials used, leading to fewer environmental hazards. This switch to a more sustainable approach can lead to companies experiencing higher profits and gaining competitive advantages.The implementation of the Pre-feeder machine can lead to more streamlined and efficient packaging processes. This change can lead to producers experiencing faster timelines, fewer material and labor costs, and increased profitability.The packaging industry continues to evolve, and companies need to adopt innovative technologies to stay ahead of the competition. The Pre-feeder machine promises to shake up the traditional packaging industry and lead to more efficient and sustainable manufacturing processes.ConclusionIn conclusion, the Pre-feeder Proves to Change the Packaging Industry with Automated Efficiency. With the rise of e-commerce and the growing demand for packaged goods, companies must adopt innovative technologies to increase production efficiency, reduce production costs, and decrease material waste. The Pre-feeder machine presents an opportunity for these companies to automate the packaging process, leading to faster timelines, reduced costs, improved accuracy, and sustainability. The Pre-feeder machine is an investment that companies in the packaging industry cannot afford to overlook.

Read More

Find Top Ball Valve Suppliers & Exporters in India - 2 Way, 3 Way, Floating & MS Ball Valves Available

Read More

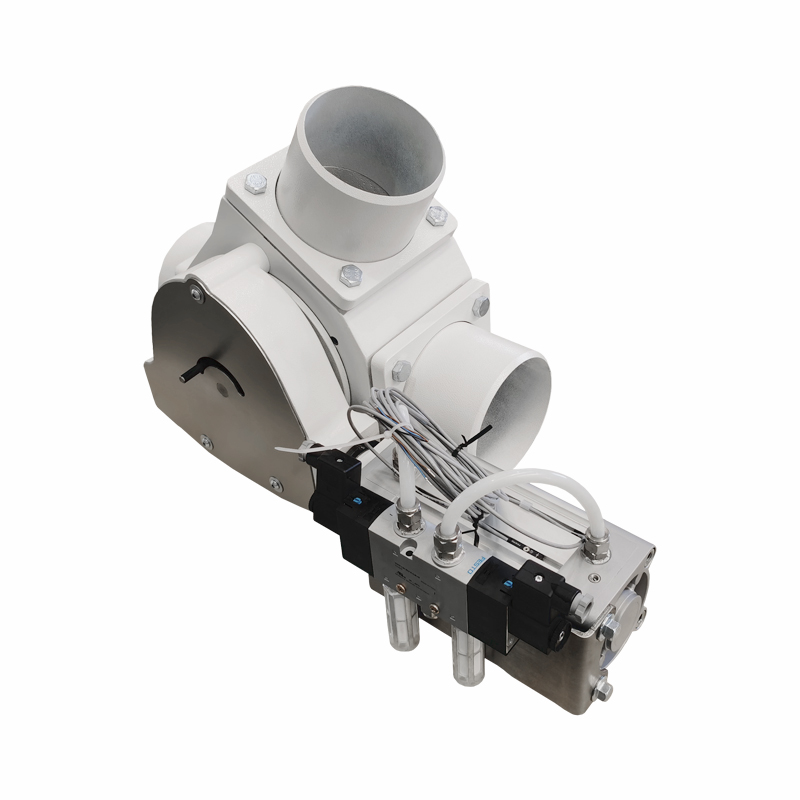

High-flow Rotary Airlock Valve: Advanced Features for Efficient Material Handling

Title: Enhancing Manufacturing Efficiency: The Versatile Drop Through Airlock Valve IntroductionIn manufacturing facilities and industrial processes, ensuring smooth material handling is crucial for efficient operations. One vital component that aids in this seamless transfer of bulk materials is the drop through airlock valve. Designed to optimize flow rates and prevent air leakage, this device has become an indispensable element in various industries. In this blog post, we will explore the notable features and benefits of a drop through airlock valve, shedding light on its significant role in enhancing manufacturing efficiency.Understanding the Drop Through Airlock ValveThe drop through airlock valve, sometimes referred to as a rotary airlock valve, is a fundamental component used in numerous industrial applications. Its primary function is to regulate the continuous flow of materials while maintaining a consistent pressure environment. The valve accomplishes this through a rotation mechanism that creates a seal between different sections of the production line, reducing air leakage and avoiding process disruptions.Key Features and Benefits1. Enhanced Flow Rate: One of the major advantages of the drop through airlock valve is its ability to handle high flow rates. Thanks to its sturdy construction and efficient design, it facilitates the transfer of bulk materials swiftly and smoothly from one processing stage to another. This feature proves vital in ensuring uninterrupted production and prevents potential bottlenecks.2. Preventing Air Leakage: Air leakage is a significant concern in various industrial processes, as it can negatively impact operating conditions and compromise product quality. The drop through airlock valve effectively isolates different pressure zones within the manufacturing line, minimizing air leakage. By maintaining a controlled environment, the valve ensures that products are handled with utmost care and consistency.3. Material Protection: In industries dealing with fragile or abrasive materials, preserving the integrity of the product during handling is of utmost importance. The drop through airlock valve prevents material degradation by providing a gentle transfer mechanism. Its precise engineering minimizes material damage, ensuring that the end product meets the desired quality standards.4. Versatile Application: The drop through airlock valve finds its utility across a multitude of industries. From pharmaceuticals and food processing to chemical manufacturing and agricultural sectors, this valve is adaptable to various material handling needs. Its customizable design, available in different sizes and materials, enables seamless integration into existing production lines.5. Durability and Low Maintenance: Industrial equipment needs to withstand rigorous operational demands. The drop through airlock valve boasts a robust construction, ensuring its longevity and minimizing maintenance requirements. With regular preventive care, this valve proves to be a cost-effective investment, providing reliable performance over an extended period.ConclusionFrom high flow rates to preserving material integrity, the drop through airlock valve offers a range of benefits that significantly boost manufacturing efficiency. Its ability to regulate the continuous flow of materials, prevent air leakage, and adapt to diverse industry needs makes it an indispensable component in various production lines. With its durable construction and low maintenance requirements, this valve proves to be a reliable and cost-effective solution for optimizing material handling processes.To enhance manufacturing efficiency and streamline operations, businesses should consider incorporating drop through airlock valves into their workflows. By leveraging the key features and benefits of this versatile device, industries can ensure smooth material transfers, reduce downtime, and ultimately enhance productivity.

Read More

Discover the Versatility and Efficiency of Manual Control Valves

Title: Industry-Leading Manual Control Valve Optimizes Precise Control and Enhances Operational EfficiencyIntroduction:In today's rapidly evolving industrial landscape, organizations across sectors are leveraging cutting-edge technologies to streamline their operations. Manual Control Valve, manufactured by a renowned company with a strong foothold in the industry, has emerged as a game-changing solution for companies seeking to enhance control precision and operational efficiency. This innovative valve offers unmatched reliability, durability, and versatility, making it an ideal choice for a wide range of applications.Paragraph 1: A Brief Overview of the Manual Control ValveThe Manual Control Valve, developed by a leading manufacturer in the industry, combines years of expertise with advanced engineering to deliver an unparalleled level of control. Designed with precision in mind, this valve offers operators the ability to precisely regulate fluid flow, pressure, and temperature in various industrial processes. Moreover, its robust construction ensures long-lasting performance, even in the most demanding environments.Paragraph 2: Unmatched Versatility for Diverse ApplicationsCompeting in a global market, industries require versatile solutions that can cater to their diverse operational needs. The Manual Control Valve successfully meets this demand as it can be employed across various domains, including oil and gas, chemical processing, power generation, and wastewater management. Whether it's controlling flow rates during extraction processes, maintaining optimal temperatures in chemical reactors, or regulating water levels in reservoirs, this valve ensures optimal performance and efficiency.Paragraph 3: Enhanced Precision for Improved ProductionManual Control Valve's exceptional precision distinguishes it from other valves available in the market. Operators can finely adjust the valve's position to precisely control flow rates and pressures, minimizing variations and maximizing production efficiency. By integrating this valve into their systems, companies can experience reduced downtime, improved product quality, and enhanced overall productivity.Paragraph 4: Rugged Construction for Durability and ReliabilityManufactured using the highest quality materials, this valve offers unmatched durability and reliability. It is built to withstand extreme conditions, such as high temperatures, corrosive environments, and intense pressure differentials without compromising functionality. The valve's superior construction ensures minimal maintenance requirements, reducing operational costs for companies and providing a long-lasting solution.Paragraph 5: Safety Features and Ease of OperationIn addition to its outstanding performance, the Manual Control Valve prioritizes safety. Equipped with fail-safe mechanisms, such as emergency shut-off features, pressure relief capabilities, and anti-locking mechanisms, it ensures the protection of personnel, equipment, and the environment. Furthermore, its user-friendly design facilitates ease of operation, minimizing the risk of errors and ensuring seamless integration into existing systems.Paragraph 6: Environmental Friendliness and Sustainable OperationRecognizing the importance of environmental stewardship, the Manual Control Valve incorporates eco-friendly features to minimize ecological impact. By optimizing flow control and reducing leakage rates, it helps conserve valuable resources. Additionally, its sustainable design complies with industry standards and regulations, ensuring a greener future for industries and communities alike.Paragraph 7: Seamless Integration and Full Customization OptionsThe Manual Control Valve can be seamlessly integrated into existing systems, making it an attractive option for companies looking to improve their operational processes without major disruptions. Moreover, the manufacturer offers full customization options, tailoring the valve's specifications to meet specific industry requirements, such as size, material, control mechanisms, and pressure and temperature limits.Conclusion:As industries continue to seek innovative solutions to optimize operational efficiency, the Manual Control Valve stands out as a superior choice. With its unrivaled precision, reliability, versatility, and safety features, it empowers companies across sectors to achieve enhanced performance, reduced costs, and sustainable operations. As technology advances, this valve will undoubtedly play a pivotal role in shaping the future of control systems, revolutionizing industrial processes, and driving overall progress in the global market.

Read More

Types of Rotary Valve: Applications, Components and Limitations of Rotary Airlock Valve - Engineering Learn

Read More

Discover the Function and Construction of Diaphragm Valves

Diaphragm valves, also known as membrane valves, are essential components of industrial plants and processes worldwide. These valves are designed to regulate the flow of fluid in pipes and pipelines with the help of a flexible diaphragm. In today's blog post, we'll discuss what diaphragm valves are, how they work, and where they are commonly used.What are Diaphragm Valves?A diaphragm valve is a type of valve with a flexible diaphragm that separates the flow of fluid from the closure element. This valve comprises a valve body with several ports, a diaphragm, and a weir or saddle that serves as the seat. The diaphragm is clamped between two halves of the valve body and pressed against the saddle to close the valve. The valve's closure mechanism can be manual, pneumatic, or electric actuation.How do Diaphragm Valves Work?Diaphragm valves work by varying the pressure on the flexible diaphragm's upstream and downstream sides. When there is no pressure difference, the diaphragm rests on the saddle, and the valve remains open. When the upstream pressure exceeds the downstream pressure, the diaphragm is lifted off the saddle, allowing the fluid to flow through the valve. Conversely, when the downstream pressure exceeds the upstream pressure, the diaphragm is pushed down onto the saddle, cutting off the fluid flow.Where are Diaphragm Valves Used?Diaphragm valves are commonly used in industries that require precise flow control and cleanliness. Some of the industries that utilize diaphragm valves include water treatment, chemical processing, pharmaceuticals, food and beverage, and biotechnology. Because diaphragm valves feature a completely closed flow path and no exposed metal parts, they are ideal for controlling sterile or corrosive liquids, toxic gases, or high-purity fluids.Benefits of Diaphragm ValvesDiaphragm valves present numerous advantages, such as a simple design, low cost, ease of maintenance, and robustness. These valves can also handle high-pressure applications and work in extreme temperatures. Additionally, the diaphragm acts as a seal between the valve body and the fluid, preventing contamination, making them an excellent choice for use in the food and beverage industry, where hygiene is paramount.ConclusionDiaphragm valves are essential components in many industrial processes that require precise flow control. They offer high resistance to corrosion and abrasion, high-purity capabilities, and flexibility concerning media and temperature. If you are looking for an affordable, reliable, and efficient flow control solution, diaphragm valves should be your go-to choice. Next time you come across these valves, you will know how they work and where they are used.

Read More